30

.

Changing The Blade

To prevent personal injury, always discon-

nect plug from power source before chang-

i

ng blades.

Using the Correct Blade

IMPORTANT:

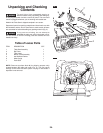

The saw blade provided on this tool has a

carbide-tipped kerf width of .128” and a plate (body) thickness

t

hat is .086” thick. When looking for a replacement blade, select

one with dimensions close to the original blade. This information

may not be printed on the blades packaging. If not, check the

m

anufacturers catalog or website. Bosch offers an extensive line

of Premium-Quality Professional Saw Blades that match the

requirements for this tool. You must select a blade with a kerf

w

idth of .092” or more and a plate (body) thickness .088” or less

(Fig. 10).

To reduce the risk of injury, do not use extra

thin kerf saw blades.

The kerf of the blade

must be wider than .092”. Extra thin kerf saw blades (less than

.092”) may cause the work piece to bind against the riving knife

during cutting. It is recommended that the kerf of the

replacement blade used on this saw be .092” or more.

To reduce the risk of injury, do not use saw

blades made with a thick body plate.

If the

replacement saw blade's plate thickness is greater than .088”,

the riving knife would not properly serve as an aid to reduce

kickback. The replacement blade's plate thickness must be less

than .088”.

To reduce the risk of injury, do not use blade

“dampeners,” “stabilizers,” or “stiffening

collars” on both sides of a replacement blade.

These are

metal plates positioned against the sides of the blade to reduce

deflection that may occur when using thin saw blades. Use of

these devices on both sides will prevent the blade from being

properly aligned with the riving knife, which may bind the work

piece during cutting. One “stabilizer” plate may be placed only

against the outside of a thin replacement blade. These plates are

not required with the supplied Bosch blade.

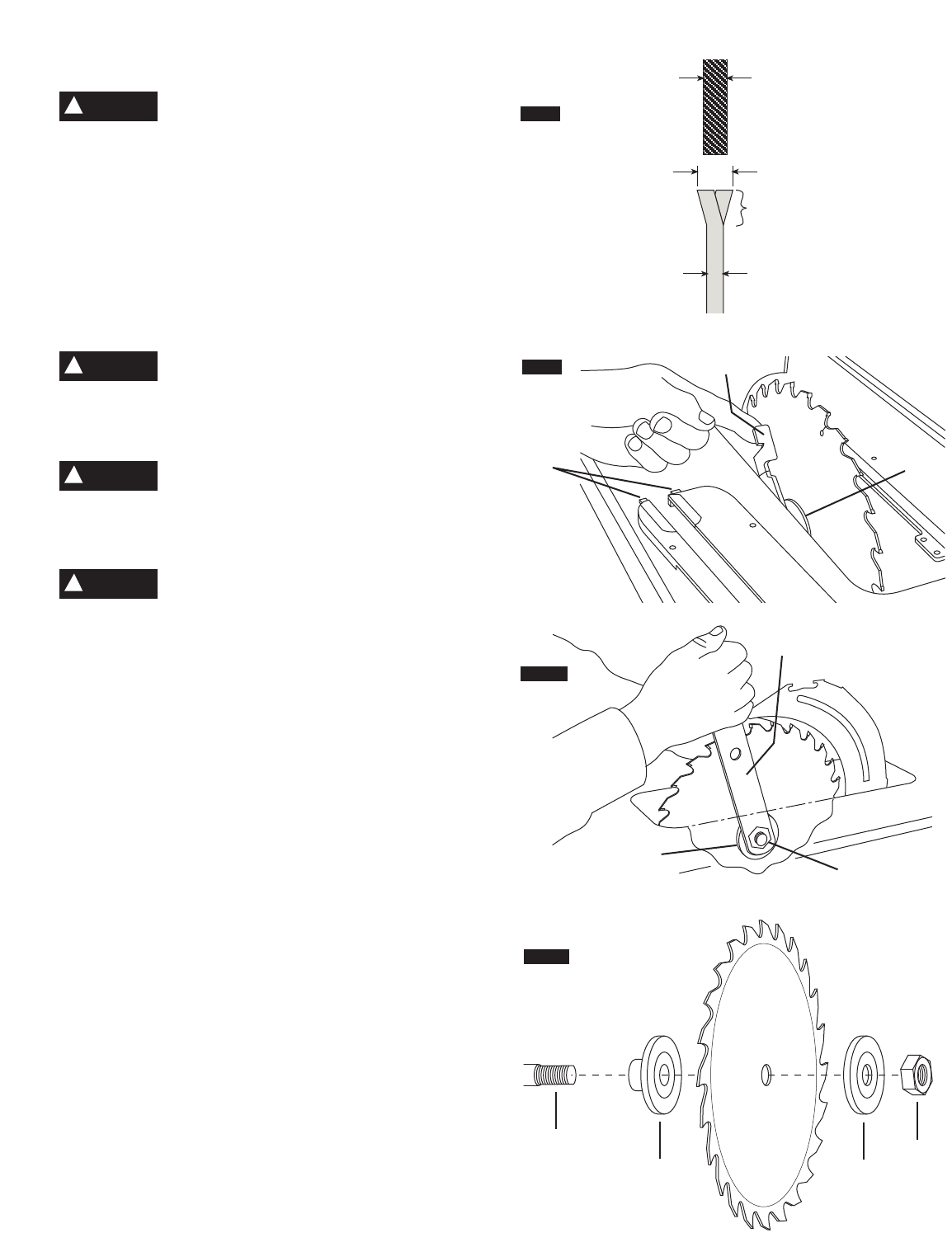

Changing the Blade

1. Turn elevation wheel clockwise until the blade is up as high as

it will go, remove table insert

1 using finger hole (Fig. 11).

2.

Lift up arbor lock lever

2 and slowly rotate blade by hand until

lock fully engages saw arbor and stops rotation (Fig. 11).

Loosen arbor nut

3 counter clockwise with the arbor wrench 4

provided (Fig. 12). Set wrench aside and continue to loosen

arbor nut

3 by hand and remove arbor nut 3 and outer washer

5. Blade may now be removed or installed by sliding on or off

arbor shaft

6.

3. Assemble inner washer

7 and new blade as shown in figure

13, making certain the TEETH OF THE BLADE ARE

POINTING DOWN AT THE FRONT OF THE TABLE.

NOTE: The printing on different saw blades are not always on

the same side.

4.

Assemble outer washer

5, arbor nut 3 as shown in figure 13.

While lifting up arbor lock lever

2 securely tighten arbor nut 3

clockwise with the wrench 4. (Fig. 12).

5. Position table insert in pocket of table so tabs

8 on table insert

1 are in slots in pocket of table and push down and secure in

place.

B

LADE BODY PLATE

P

LAQUE DU CORPS DE LA LAME

PLACA DEL CUERPO DE LA HOJA

MUST BE .088” OR LESS

DOIT ÊTRE DE 0,088 PO OU MOINS

DEBE SER 0.088 PULGADAS O MENOS

KERF WIDTH

LARGEUR DE VOIE

ANCHURA DE LA SECCIÓN DE CORTE

RIVING KNIFE

COUTEAU DIVISEUR

CUCHILLA SEPARADORA

M

UST BE .092” OR MORE

D

OIT ÊTRE DE 0,092 PO OU PLUS

DEBE SER 0.092 PULGADAS O MÁS

.

090”

BLADE TEETH

DENTS DE LA SCIE

DIENTES DE LA HOJA

FIG. 12

FIG. 13

2

7

1

FIG. 11

FIG. 10

8

3

4

5

W

ARNING

!

WARNING

!

WARNING

!

WARNING

!

3

5

7

6