-15-

USING SELF-PILOTED BITS

Self-piloted bits have an integral round tip or

ball bearing which rides against the work

surface above or below the cutter to control

horizontal cutting depth (Fig. 17). When using

these bits, neither the roller guide or the

straight guide is required. When guiding

against a laminated surface, use wax or other

lubricant and do not apply excess pressure or

the piloted end may mar the work. Bearing

pilots must be kept clean and free of adhesive

or other residue. Router bit bearings are

sealed and permanently lubricated, and should

be replaced when they no longer turn freely to

avoid damaging the work surface.

PR003 ROLLER/BUSHING GUIDE

(Included with PR20EVSNK, also available as

optional accessory)

The optional PR003 Roller/Bushing Guide is

used when edge-forming or trimming with

unpiloted bits, non-bearing bits.

Attachment of Roller/Bushing Guide

The PR003 roller/bushing guide (Fig. 18) is

attached using the wing screw and washer.

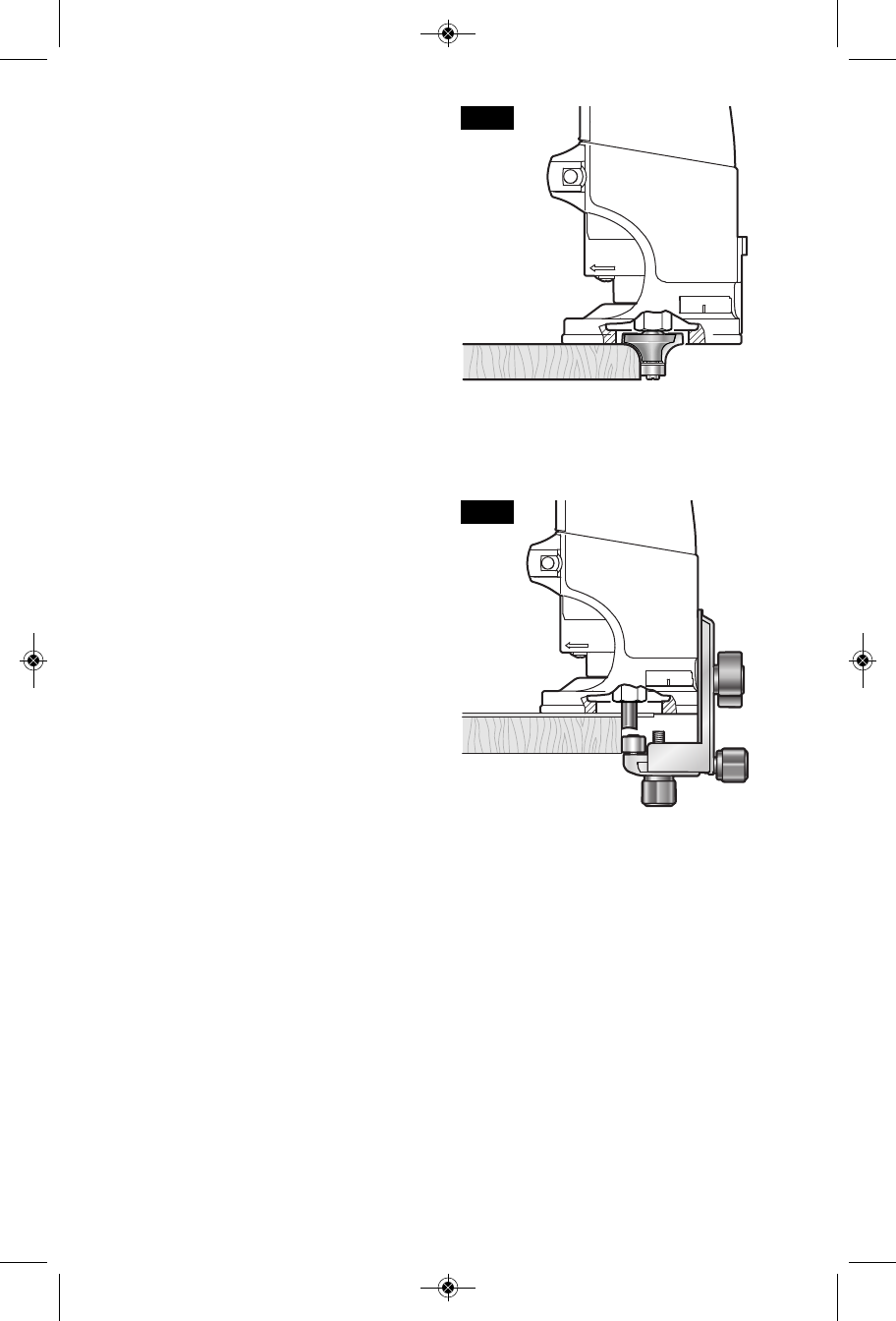

Adjustment of Roller/Bushing Guide

Vertical Adjustment:

1. Loosen the wing screw and adjust up or

down as necessary to allow roller/bushing to

ride on the intended guiding surface.

2. Tighten wing screw.

Horizontal Adjustment:

Whether making straight or bevel cuts, the

width of material removed is determined by the

distance between the front of the router bit’s

cutter and the front of the roller/bushing. Adjust

the front of the roller/bushing as follows:

1. Loosen wing nut at bottom.

2. Rotate the wing nut on the back of the guide

to move the roller/bushing in or out to create

amount of cutter exposure needed to trim

the laminate flush with the guiding surface or

to create the desired bevel.

3. Be sure the bit clears the top of the

roller/bushing guide by at least 1/8" (3 mm)

to avoid damage.

4. Tighten wing nut on the bottom of the guide

assembly

5. Make a trial cut to check the setting and

readjust as necessary.

Use of the Roller/Bushing Guide

1. With the guide installed and adjusted, the

router should be fed normally, keeping the

guide in contact with the edge of the

workpiece at all times.

2. To maintain a consistent width of cut, a

consistent angle must be maintained

between the router and the workpiece.

FIG. 17

FIG. 18

BM 2610021461 06-12_BM 2610021461 06-12.qxp 6/26/12 1:38 PM Page 15