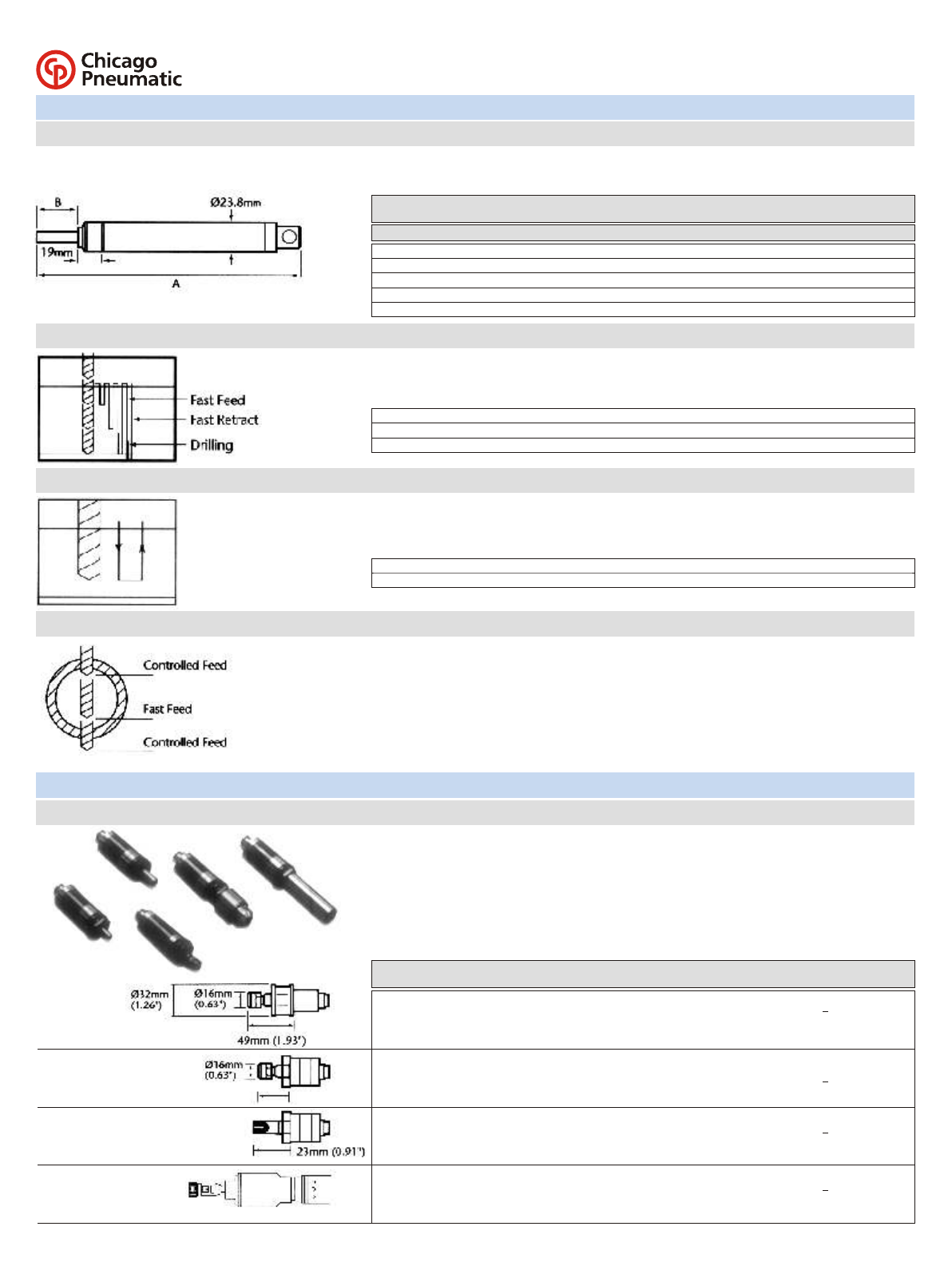

l Interchangeable modular output spindles

l Precision option for collet types, R2 and R36

Used when hole depth is five times hole diameter. Helps clear chips, avoids overheating and bit

breakage. Hole accuracy is improved. For use with Full Feature Control Block.

peck feed control

25mm (1”) stroke 92282

50mm (2”) stroke 92292

75mm (3”) stroke 92302

D4

D5

D6

Minimises burring on breakthrough. Constant feed maintained in all operating conditions.

Hydraulic fluid sealed for life.

9

AFD Control Options

adjustable feed control unit

2.3 544 0.73 25 199 30.1 91942

2.3 544 0.73 50 276 55.5 91952

2.3 544 0.73 75 352 80.9 91962

4.1 357 0.45 102 417 106 104452

4.1 357 0.45 127 474 132 104462

MIN. PLUNGER MAX. LOAD MINIMUM FEED RATE MAX. STROKE A B PART NO.

OPERATING LOAD AT 2230N (500LBS) LOAD

kg kg mm mm mm mm

D1

D2

D3

D7

D8

Used to dwell drill at bottom of stroke. Can be used to spot face, blind hole polish, friction weld

plastic components and spin rivet. For use with Full Feature Control Block.

dwell control

Dwell Control Unit Complete 92372

Dwell for AFD60 78482

E1

—

skip feed control

Skip Drilling – custom H.C.U.’s available on request.

Skip control ensures minimum cycle times without

breakthrough burrs when drilling tubes, pocketed

castings etc, with two controlled feed movements

linked by a distance of fast travel.

Information Required

1. Depth of first cut

2. Depth of skip

3. Depth of second cut

4. Drill point anlge

AFD205 / AFD215, AFDE200, AFTE270

Output Spindles

High Speed Output K42 Collect Chuck can be fitted to any AFDE200 375263 <5250 rpm

Spindle to step up speed by 4.28 : 1.

Note: Max allowable speed 27000 rpm.

FUNCTION ORDER FEATURES PART NO. RECOMMENDED

CODE SPEED RANGE

Collect Chuck K2 See range of collets. 357183 <18800 rpm

No. 1 Jacobs Taper K32 No. 1 Jacobs Taper and for use with chucks or. 382213 <9600 rpm

Output Spindle multi spindle heads

Tapping Head H21 4.5-8.0MM (3/16”-5/16”) capacity. 357193 <1200 rpm

Output Spindle

25.5mm (1”)