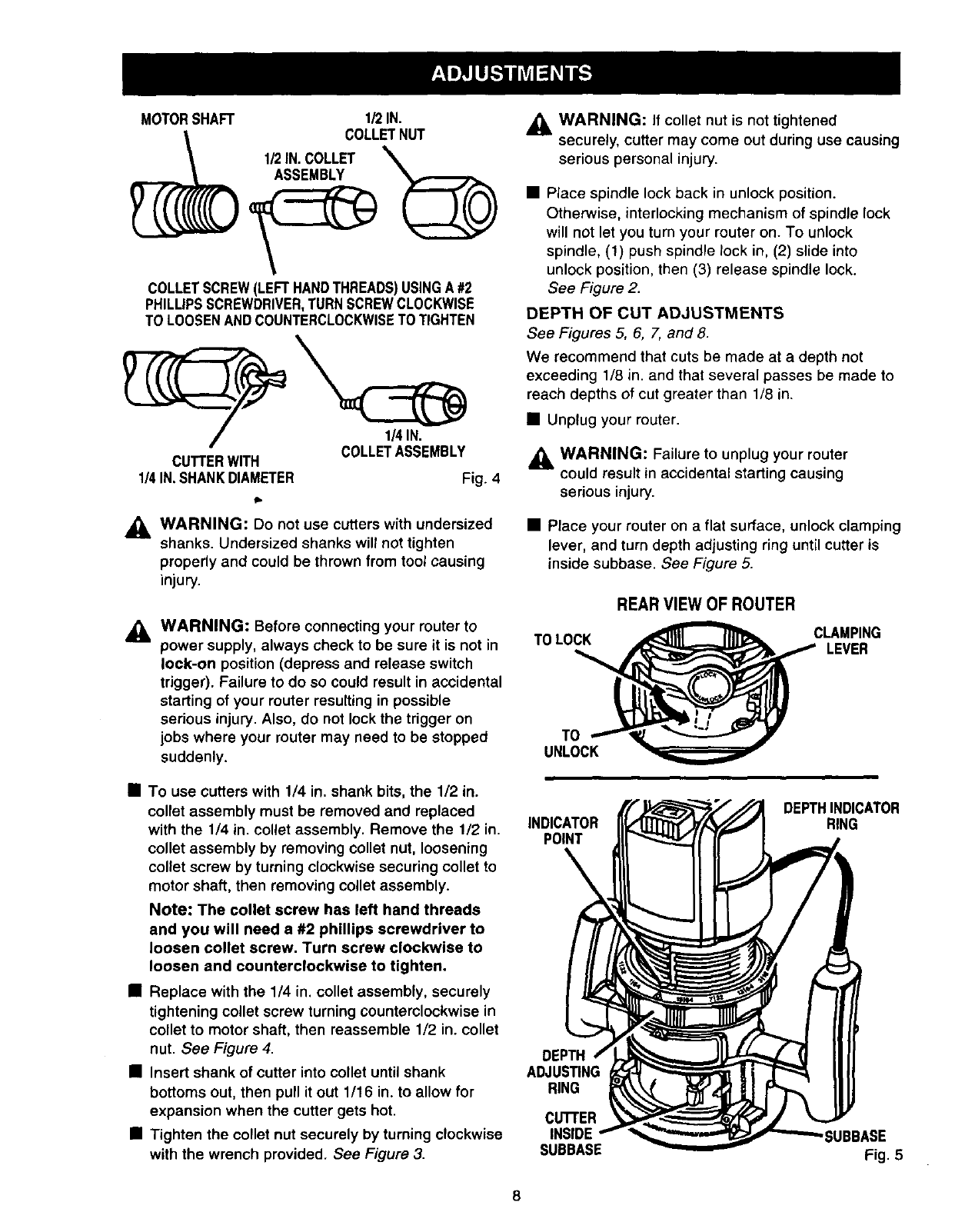

MOTORSHAFT 1/2IN.

COLLETSCREW(LEFTHANDTHREADS)USINGA#2

PHILLIPSSCREWDRIVER,TURNSCREWCLOCKWISE

TOLOOSENANDCOUNTERCLOCKWISETO TIGHTEN

COLLETASSEMBLY

CUTTERWITH

1/4IN.SHANKDIAMETER Fig. 4

_1= WARNING: Do not use cutters with undersized

shanks. Undersized shanks will not tighten

properly and could be thrown from tool causing

injury.

_, WARNING: Before connecting your router to

power supply, always check to be sure it is not in

lock-on position (depress and release switch

trigger). Failure to do so could result in accidental

starting of your muter resulting in possible

serious injury. Also, do not lock the trigger on

jobs where your router may need to be stopped

suddenly.

,_ WARNING: If collet nut is not tightened

securely, cutter may come out during use causing

serious personal injury.

• Place spindle lock back in unlock position.

Otherwise, interlocking mechanism of spindle lock

will not let you turn your router on. To unlock

spindle, (!) push spindle lock in, (2) slide into

unlock position, then (3) release spindle lock.

See Figure 2.

DEPTH OF CUT ADJUSTMENTS

See Figures 5, 6, 7, and 8.

We recommend that cuts be made at a depth not

exceeding 1/8 in. and that several passes be made to

reach depths of cut greater than 1/8 in.

• Unplug your router.

_, WARNING: Failure to unplug your router

could result in accidental starting causing

serious injury.

• Place your router on a flat surface, unlock clamping

lever, and turn depth adjusting ring until cutter is

inside subbase. See Figure 5.

REAR VIEW OF ROUTER

TOLOCK CLAMPING

LEVER

TO

UNLOCK

• To use cutters with 1/4 in. shank bits, the 1/2 in.

collet assembly must be removed and replaced

with the 1/4 in. collet assembly. Remove the 1/2 in. INDICATOR

POINT

collet assembly by removing toilet nut, loosening

collet screw by turning clockwise securing collet to

motor shaft, then removing collet assembly.

Note: The collet screw has left hand threads

and you will need a #2 phillips screwdriver to

loosen collet screw. Turn screw clockwise to

loosen and counterclockwise to tighten.

• Replace with the 1/4 in, collet assembly, securely

tightening collet screw turning counterclockwise in

collet to motor shaft, then reassemble 1/2 in. collet

nut. See Figure 4. DEPTH

• Insert shank of cutter into collet until shank ADJUSTING

bottoms out, then pull itout 1/16 in. to allow for RING

expansion when the cutter gets hot. CUTTER

• Tighten the collet nut securely by turning clockwise INSIDE

with the wrench provided. See Figure 3. SUBBASE

DEPTHINDICATOR

RING

SUBBASE

Fig. 5

8