10

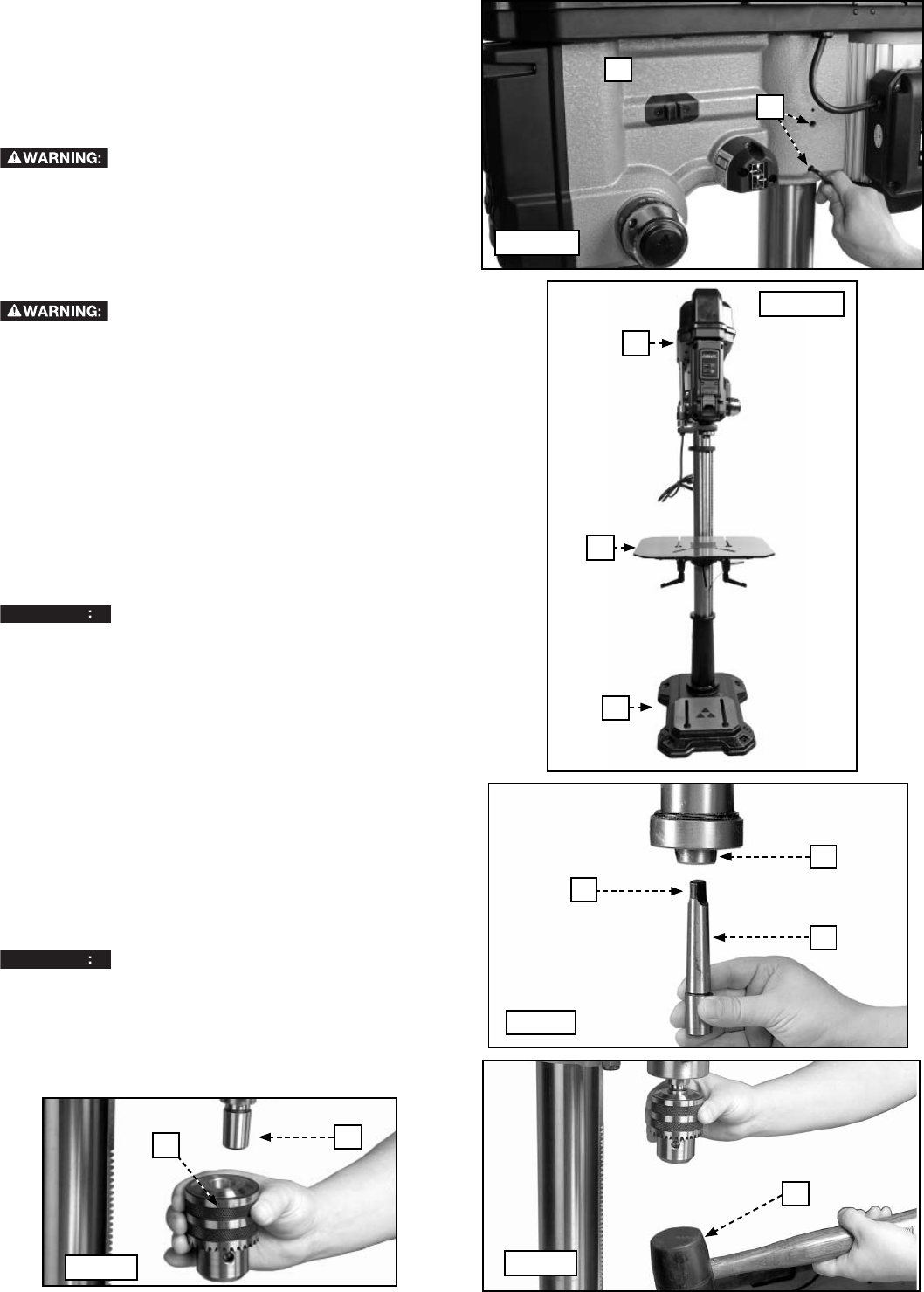

Fig. 12

Y

X

Fig. 13

Z

ASSEMBLING HEADSTOCK

TO COLUMN AND BASE

To assemble the headstock to the column:

1. Place the drill press head (P) Fig. 9 on the column as far

as it will go.

NOTE: Be sure the head-locking screws (R) are do not

block the drill press head from fully seating on the column.

To reduce the risk of injury, always use at

least two people when lifting.

2. Align the head (P) Fig. 10 with the table (Q) and the

base (B).

3. Tighten the two head-locking screws (R) Fig. 9 with the

5 mm hex wrench supplied.

INSTALLING THE CHUCK

To reduce the risk of injury, turn unit off

and disconnect it from power source before installing

and removing accessories, before adjusting or when

making repairs. An accidental start-up can cause injury.

IMPORTANT: Make certain that the tapered hole in the

bottom of spindle (U) Fig. 11, and the taper on the spindle

adapter (V) are clean and free of grease, lacquer or rust-

preventive coatings.

NOTE: Remove the rust-preventative oil from the chuck

using a soft cloth moistened with mineral spirits, paint

thinner or denatured alcohol.

Push the spindle adapter (V) Fig. 11 into the spindle (U).

making certain that the tang (W) engages the mating slot

inside the spindle (U).

NOTICE

RISK OF PROPERTY DAMAGE. To avoid

damage to the laser, prevent the cleaning solution from

coming in contact with the laser pod. You can clean the

laser pod with a dry cotton cloth.

IMPORTANT: Make certain the spindle taper (X) Fig. 12, and

tapered hole in chuck (Y) are clean and free of any grease,

lacquer or rust preventive coatings.

NOTE: Remove the rust-preventative oil from the chuck

using a soft cloth moistened with mineral spirits, paint

thinner or denatured alcohol.

IMPORTANT: Rotate the chuck until the chuck jaws are

fully retracted inside the chuck. Hold the chuck on the taper

of the spindle. Tap it with a soft-tip hammer (Z) Fig. 13 or a

block of wood and hammer to set the chuck.

NOTICE

RISK OF PROPERTY DAMAGE. To avoid

damage to the chuck, NEVER drive the chuck on the spindle

with a metal hammer.

Fig. 11

U

V

W

P

Fig. 9

R

P

Fig. 10

Q

B