12—ENG

MGP-SL10120H-2A

INSTALLATION AND BREAK-IN PROCEDURES

Piping

NoteNote

NoteNote

Note

For underground installation, bury air

lines below the frost line and avoid

pockets where condensation can gather

and freeze. Apply pressure before un-

derground lines are covered to make

sure all pipe joints are free from leaks.

Plastic or PVC pipe is not designed for use

with compressed air. Regardless of its indi-

cated pressure rating, plastic pipe can burst

from air pressure. Use only metal pipe for

air distribution lines.

NoteNote

NoteNote

Note

Where a remote air intake is used, en-

large the size of the air intake piping by

one pipe size for each 10 feet of length.

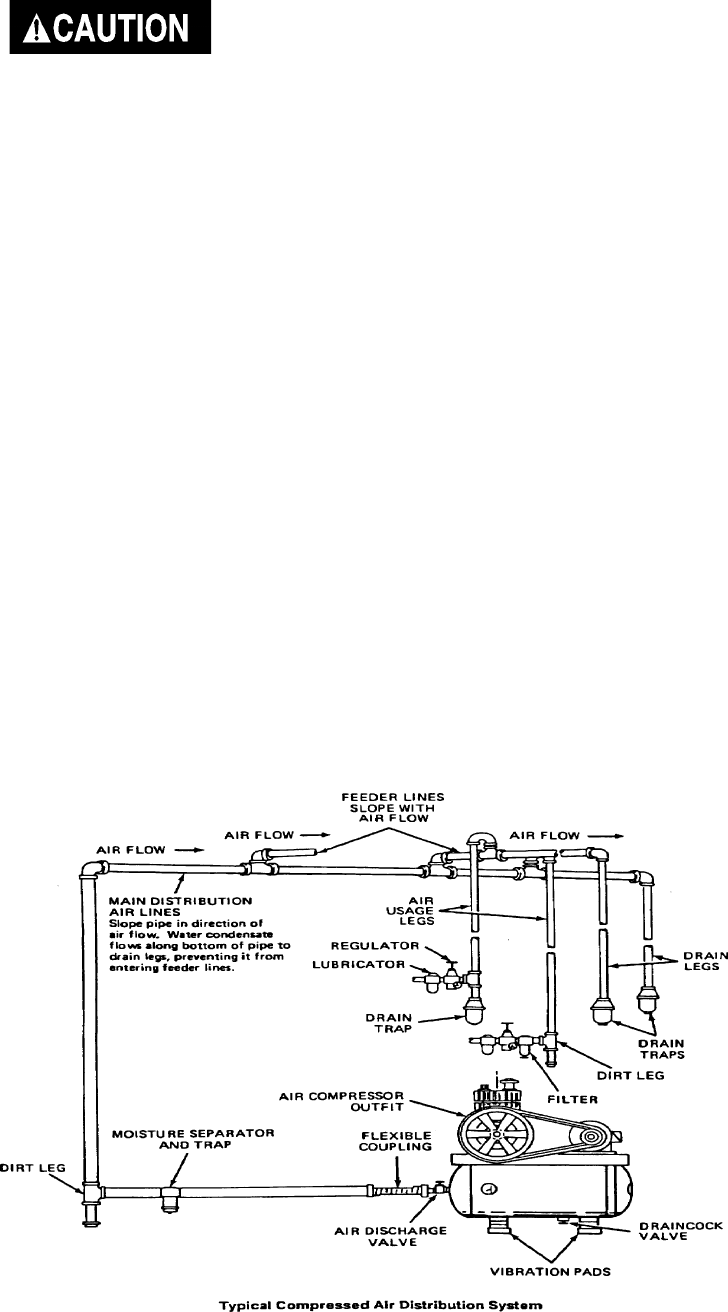

A typical compressed air distribution system as shown

below should be of sufficient pipe size to keep the

pressure drop between the supply and point of use to a

minimum. All pipes and fittings used must be certified

safe for the pressures involved. Pipe thread sealant must

be used on all threads, and all joints are to be made up

tight, since small leaks in the piping system are the

largest single cause of high operating costs.

All piping should be sloped to an accessible drain point

and all outlets should be taken from the top of the main

distribution air line so that moisture cannot enter the

outlet.

The main distribution air line should not be smaller than

the compressor air discharge valve outlet. A smaller line

will restrict the flow of air. If piping is over 100 feet long,

or if required air flow will exceed 15 SCFM, use 3/4"

piping.

It is recommended that a flexible coupling be installed

between the air discharge valve outlet and main air

distribution line to allow for vibration.

To remove dirt, oil and water, install a separator in the

main distribution line. Install separator a minimum of 5 to

6 feet from compressor to allow the air to cool to room

temperature before passing through the separator. Addi-

tional separators or filters may be used depending on the

application.

Liquid water occurs naturally in air lines as a result of

compression. Moisture vapor in ambient air is concen-

trated when pressurized and condenses when cooled in

downstream air piping. Compressed air dryers reduce

the water vapor concentration and prevent liquid water

formation in compressed air lines. Dryers are a neces-

sary companion to filters, aftercoolers, and automatic

drains for improving the productivity of compressed air

systems.

Water and water vapor removal increases the efficiency

of air operated equipment, reduces contamination and

rusting, increases the service life of pneumatic equip-

ment and tools, prevents air line freeze-ups, and reduces

product rejects. The use of dryers and filters are recom-

mended when these moisture related problems are

reported to our factory or distributor service department.