English

5

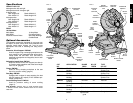

4. Depress the spindle lock button (Fig. 3) while carefully

rotating the saw blade by hand until the lock engages.

5. Keeping the button depressed, use the other hand and

the wrench provided (D) to loosen the blade screw.

(Turn clockwise, left-hand threads)

6. Remove the blade screw (E), outer clamp washer (F),

and blade (G). The 1" (25.4mm) blade adapter (H), if

used, and the inner clamp washer (I), may be left on

the spindle.

NOTE: For blades with a blade hole of 5/8" (15.88mm), the

1" (25.4mm) blade adapter is not used.

Installing a Blade

1. Unplug the saw.

2. With the arm raised, the lower guard held open and the

pivot plate raised, place the blade on the spindle, onto

the blade adapter [if using a blade with a 1" (25.4mm)

diameter blade hole] and against the inner clamp

washer with the teeth at the bottom of the blade point-

ing toward the back of the saw.

3. Assemble the outer clamp washer onto the spindle.

4. Install the blade screw and, engaging the spindle lock,

tighten the screw firmly with wrench provided. (Turn

counterclockwise, left-hand threads)

NOTE: When using blades with a 5/8" (15.88mm) diame-

ter blade hole, the blade adapter will not be used and

should be stored in a safe place for future use.

5. Return the guard bracket to its original position and

firmly tighten the guard bracket screw to hold bracket

in place.

WARNING:

• The guard bracket must be returned to

its original position and the screw

tightened before activating the saw.

• Failure to do so may allow the guard

to contact the spinning saw blade

resulting in damage to the saw and

severe personal injury.

Installing Extension Kit

Side Table Extension (Some Models)

BE SURE TO OBSERVE ALL OF THE SAFETY

INSTRUCTIONS IN YOUR MITER SAW INSTRUCTION

MANUAL.

UNPLUG THE MITER SAW BEFORE INSTALLING,

ADJUSTING OR REMOVING THE EXTENSION KIT.

The extension kit can be used on either or both sides of the

saw. The supplied extension kit is factory installed on the

left side:

1. Install the self-tapping stud into the hole underneath

the saw.

2. Install extension tube making sure the clamping brack-

et will catch the legs.

3. Tighten clamping bracket against the legs.

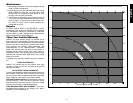

45

5

5

40

3

5

50

4

5

FIG. 4

LOCK

DOWN

PIN

FIG. 5

G

F

E

DISTANCE FROM

BLADE MUST BE

EQUAL

I

FIG. 6

A

H

WARNING: Do not lift, support, or carry the miter saw

by the extension kit. To do so may cause tipping and loss

of control, leading to personal injury.

NOTE: Before transporting the saw, remove the extension

or telescope it into the base.

Rear Lower Guard Adjustment

Check the rear lower guard to ensure that it is located such

that the saw blade is in the center and equidistant from

each side, as shown in Figures 6 and 7. Adjust as neces-

sary by loosening the two screws and moving the guard.

Firmly tighten both screws. Never remove this guard.

Transporting the Saw

TURN OFF AND UNPLUG THE MITER SAW BEFORE

ATTEMPTING TO MOVE IT OR MAKE ANY ADJUST-

MENTS WHAT-SO-EVER!

In order to conveniently carry the miter saw from place to

place, a carrying handle has been included on the top of

the saw arm, as shown in Figure 3. To transport the saw,

lower the arm and depress the lock down pin shown in

Figure 4.

Adjustments

PERFORM ALL ADJUSTMENTS WITH THE MITER

SAW UNPLUGGED

NOTE: Your miter saw is fully and accurately adjusted at

the factory at the time of manufacture. If readjustment due

to shipping and handling or any other reason is required,

follow the steps below to adjust your saw.

Once made, these adjustments should remain accurate.

Take a little time now to follow these directions carefully to

maintain the accuracy of which your saw is capable.

MITER SCALE ADJUSTMENT

Place a square against the saw’s fence and blade, as

shown in Figure 8. (Do not touch the tips of the blade teeth

with the square. To do so will cause an inaccurate meas-

urement.) Loosen the miter clamp knob (see Fig. 9) and

swing the miter arm until the miter latch locks it at the 0

miter position. Do not tighten the clamp knob. If the saw

blade is not exactly perpendicular to the fence, loosen the

three screws that hold the miter scale to the base (shown

in Fig. 9) and move the scale/miter arm assembly left or

right until the blade is perpendicular to the fence, as meas-

ured with the square. Retighten the three screws. Pay no

attention to the reading of the miter pointer at this point.

MITER POINTER ADJUSTMENT

Loosen the miter clamp knob and squeeze the miter latch

to move the miter arm to the zero position, as shown in

Figure 9. With the miter clamp knob loose allow the miter

latch to snap into place as you rotate the miter arm past

zero. Observe the pointer and miter scale through the

viewing opening shown in Figure 10. If the pointer does

not indicate exactly zero, gently pry it left or right using a

flat bladed screwdriver.

A

B

D