Dukane Manual Part No. 403-570-01

Page 63

Section 7 - Optimizing Performance

Since weld depth affects the joint strength and the amount

of ash generated, it is important to design the weld joint

properly to meet both requirements simultaneously. The

incorporation of ash trap features is recommended to

produce acceptable appearance without compromising

strength.

Hold

During the hold phase, vertical press travel initially brings

the molten parts closer together (dynamic hold) and

then allows the molten material to solidify (static hold).

Amourphous plastics will normally take longer to solidify

than semicrystalline plastics. The dynamic hold distance is

typically a small value compared to the weld distance. An

approximate staring point for initial application setup is 10%

of weld distance. The static hold time can vary depending on

the size of the part, but is usually in the 1-3 second range.

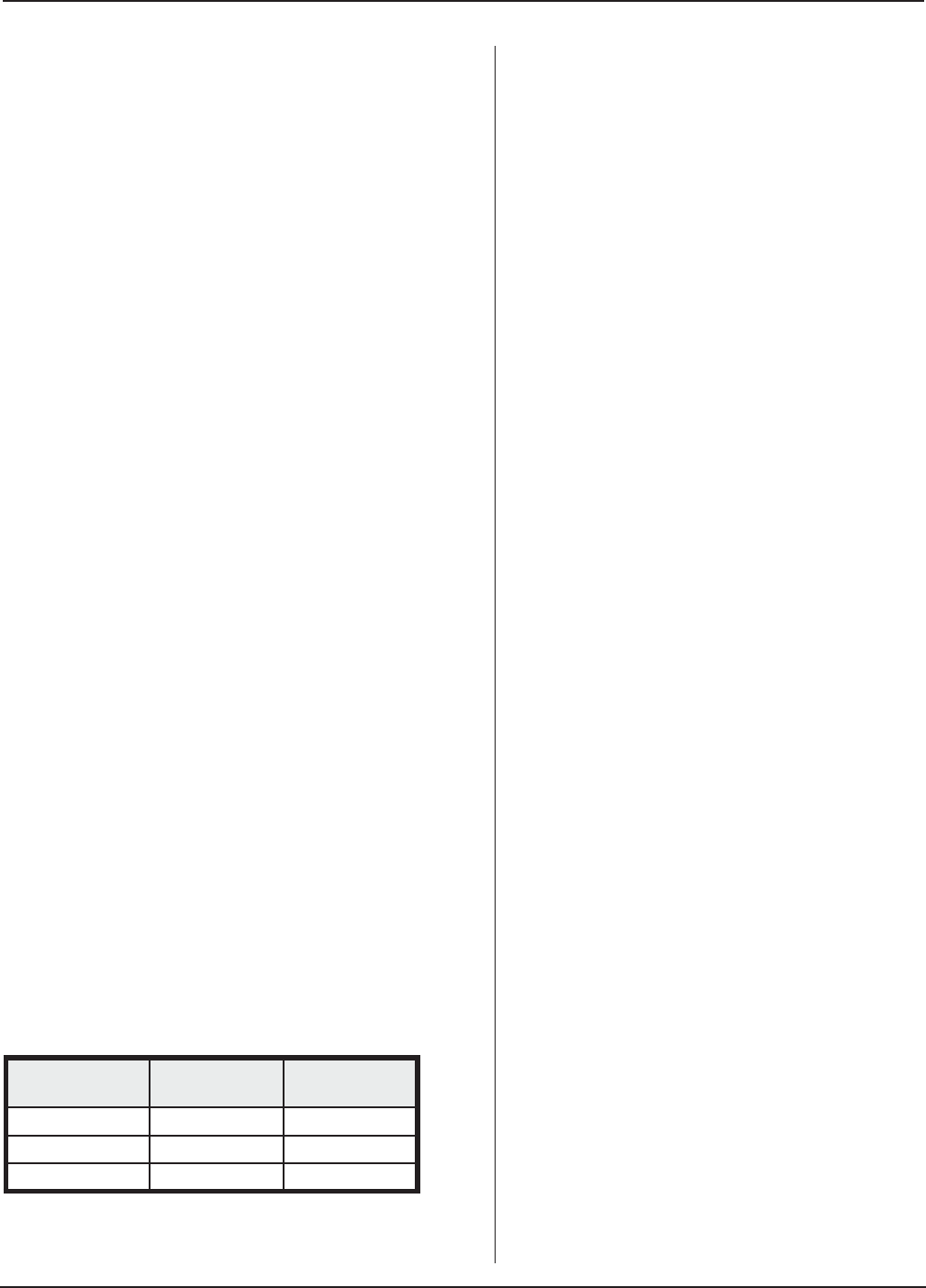

Weld Diameter

Range (in)

Machine

Model

Peak RPM

up to 2.0 SVT042VR 4000

.5 to 4 SVT032VR 3000

4 to 7 SVT012VR 750

Table 7- I

Part Size

Machine model selection will mostly depend on the weld

diameter of the parts. Refer to Table 7-I for approximate

guidelines.

For diameters under 4 inches, the SVT032VR model is

recommended due to its torque capacity. The SVT042VR

model is used where high RPM (>3000) is required.

Please contact the Dukane Applications Laboratory (see

Chapter 11) for a recommendation concerning your specic

application.