17

Maintenance

1. After the first 10 hours of working, empty the crank case

of oil and refill with clean oil by removing the crank case

oil plug (left hand side of the crank case at the bottom)

Note. Use good quality compressor lubricating oil.

• SAE30 or L-DAB 100 over 10°C

2. After each subsequent 250 hours of operation, again

drain the oil and refill the crank case with clean oil.

3. After each day of operation unscrew the two drain cocks

(9) under the tanks to drain out any condensation that

is in the tanks. This will protect the tanks from rusting

and prolong the product life. Once the draining has

been completed screw the drain cocks (9)closed and re

assemble the air compressor.

Note. Both tanks have independent drain cocks and both

have to be drained after each day of use.

CAUTION. The top tank must be removed from the

compressor prior to draining every time.

4. Regularly check the air filter insert cartridge inside the

air filter assembly (15) and clean or replace the insert

when necessary.

5. Check daily the operation of the safety valves (7). This

check should be performed when the tank contains close

to max pressure in the tank.

To check the valves, pressurise the tank, and pull the ring

OUTWARDS on the safety valve.

Air should discharge from the valve.

Release the ring of the safety valves. When the ring is

released the air discharge must stop.

WARNINGS.

Safety glasses must be worn when performing this test.

Do not have your face close to the safety valve when

performing this test as air will discharge from the valve at a

high force.

If the safety valve does not operate correctly in any way as

described above, turn off the compressor immediately and

have the compressor and safety valve checked and tested

at an authorised Service centre.

DO NOT CONTINUE TO USE THE COMPRESSOR

IN ANY WAY IF THE SAFETY VALVE DOES NOT

WORK AS ABOVE.

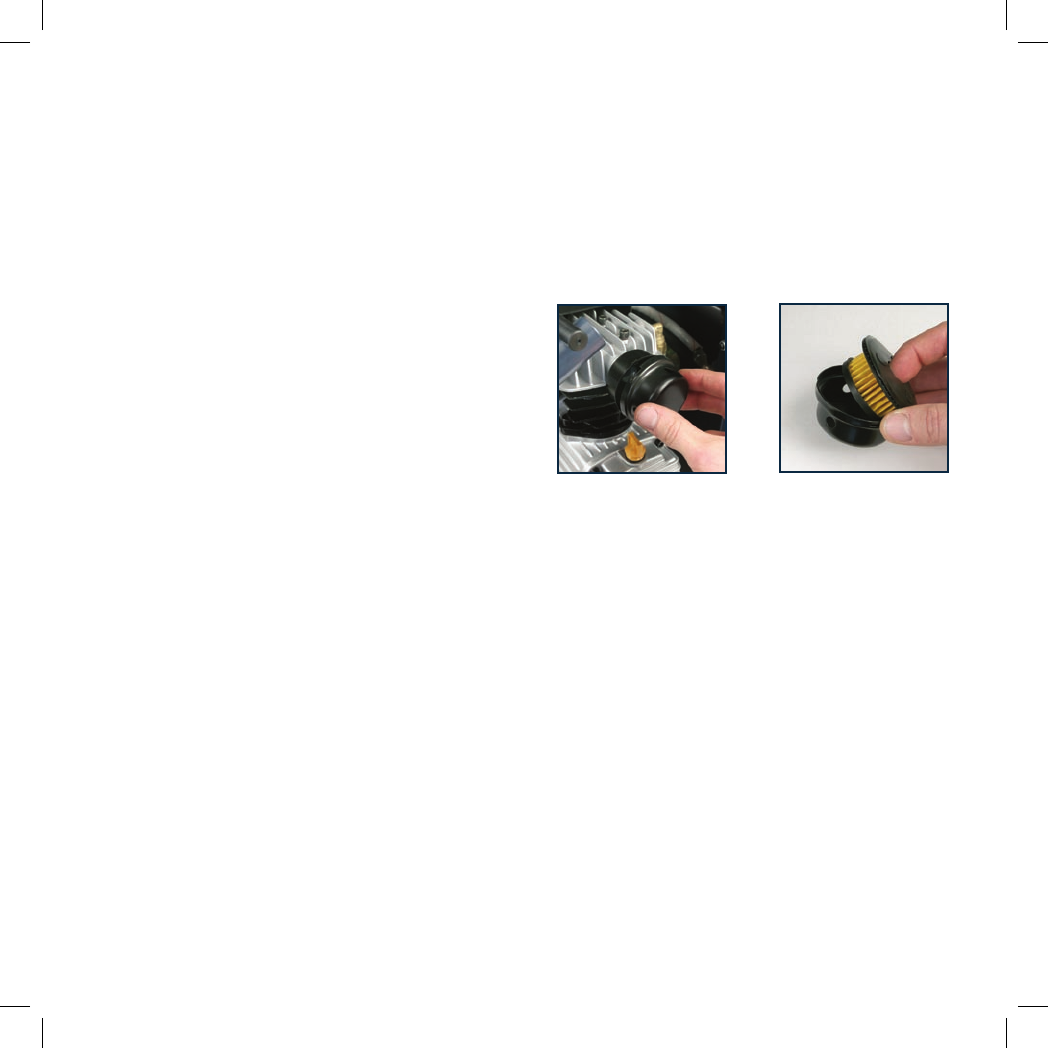

Maintaining the air filter

1. To clean the air filter insert you need to take the air filter

(15) apart first. Remove the cover along by twisting it

anti-clockwise.

2. Pull out the air filter and tap it a few times against a

surface that is dry and clean to loosen up and remove

any dust and build up. Then vacuum it for a minute or so

to draw out the more stubborn particles.

3. Replace the air filter insert cartridge, then re-install the

filter cover back on by firstly lining up the lugs and then

twisting it clockwise, to lock into position.

General inspection

1. Regularly check that all the fixing screws are tight.

2. The supply cord of the tool should be checked frequently

for damage. If damaged, have the cordset replaced by an

authorised service facility to avoid

a hazard.

Cleaning

1. Keep the tool’s air vents unclogged and clean at

all times.

2. Remove dust and dirt regularly. Cleaning is best done

with a soft brush or a rag.

3. Re-lubricate all moving parts at regular intervals.