12 308–293

Setup

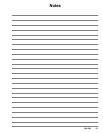

6. Adjust the Spray Pattern

(continued)

E. Open

the pattern adjustment valve (13a) by turning

it fully counterclockwise for a full fan pattern.

02017

Fig. 12

13a

Open

(wider

pattern)

Close

(narrower

pattern*)

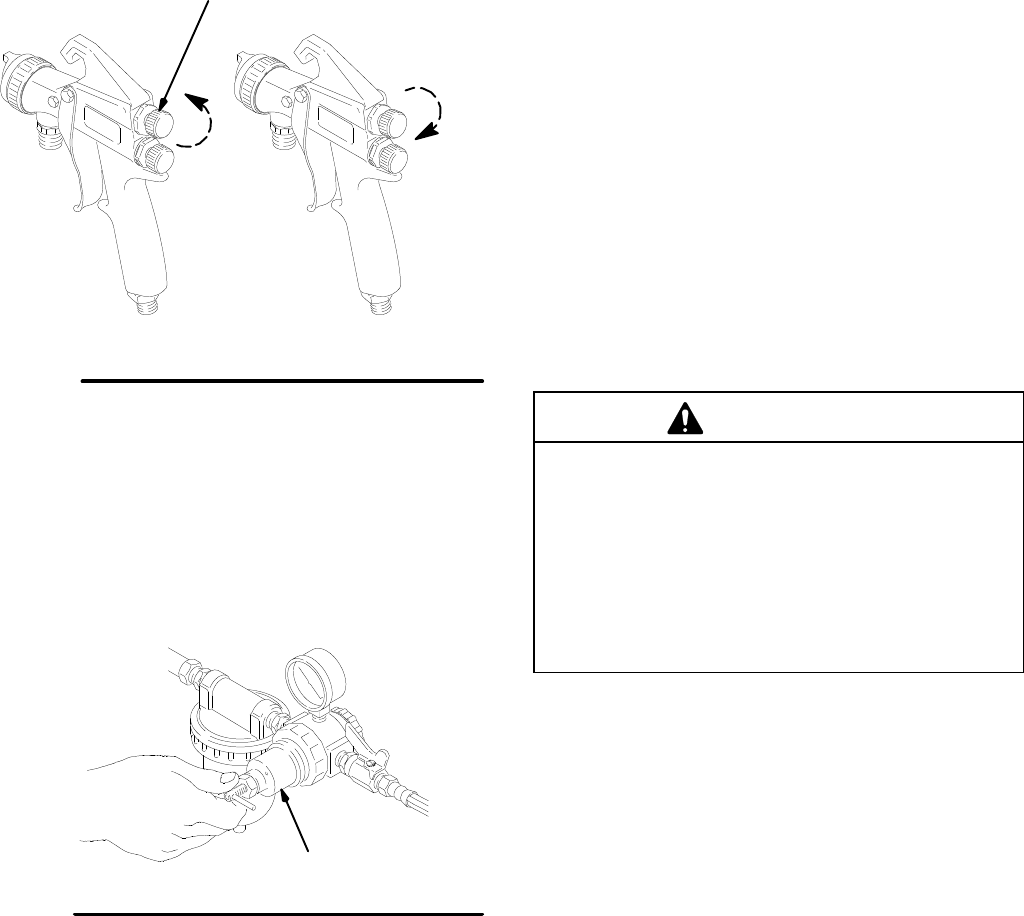

F.

Using the air pressure regulator (F), set the gun air

supply pressure at 50 psi (345 kPa, 3.4 bar) at the

gun inlet.

If available, use the fluid manufacturer

’

s recom

-

mendations to set the air line pressure for a high

volume, low pressure, spray gun application.

NOTE:

Local laws may limit the maximum pres

-

sure to 10 psi (70 kPa, 0.7 bar) at the air cap for

HVLP compliance.

Fig. 13

F

01997

G. T

est the spray pattern and atomization while hold

-

ing the gun about 6 to 8 inches (150 to 200 mm)

from the test piece.

H.

The spray pattern may be too wide with the pattern

adjustment knob (13a) turned fully counterclock

-

wise. T

urn the pattern adjustment knob clockwise

until you have the desired pattern size.

NOTE:

Turning

the pattern adjustment knob fully

clockwise will produce a round pattern.

I.

Check the atomization quality again. Increase the

gun air supply pressure with the air pressure regu

-

lator in 5 psi (34 kPa, 0.3 bar) increments until you

obtain the desired atomization.

J.

If after increasing the gun air supply pressure the

atomization is still unacceptable, try installing a

larger fluid nozzle size to reduce the fluid velocity

.

Refer to Fig. 10. Repeat steps 6-E to 6-I until you

obtain the desired atomization.

CAUTION

T

rigger the gun whenever you tighten or remove the

nozzle. This keeps the needle seat away from the

nozzle seating surface and prevents the seat from

being scratched.

When tightening the nozzle, do not exceed 35 in-lbs

(4 N

Sm)

torque. Over-tightening the nozzle can cause

the nozzle hex to round, can affect the spray pattern,

and

is unnecessary to guarantee a seal.