308–293 13

Operation

Pressure Relief Procedure

WARNING

PRESSURIZED

EQUIPMENT HAZARD

The system pressure must be manually relieved to

prevent the system from starting or spraying acci

-

dentally. T

o reduce the risk of an injury from acci

-

dental spray from the gun, splashing fluid, or

moving parts, follow the

Pressure Relief Proce

-

dure

whenever you:

D

are instructed to relieve the pressure,

D

stop spraying,

D

check or service any of the system equipment,

D

or install or clean the spray nozzle.

1. T

urn of

f the air and fluid supply to the gun.

2. T

rigger the gun into a grounded metal waste

container to relieve air and fluid pressure.

Applying the Fluid

When

using the HVLP spray gun, instead of a conven

-

tional air spray gun, you may need to use a slightly

slower hand movement and make fewer passes with

the gun to coat a part. This is due to the reduced spray

velocity produced by lower HVLP air pressures, along

with a larger fluid particle size because there is less air

to blow of

f solvents than what is produced by conven

-

tional air spray

. T

ake care to avoid runs or sags as you

spray.

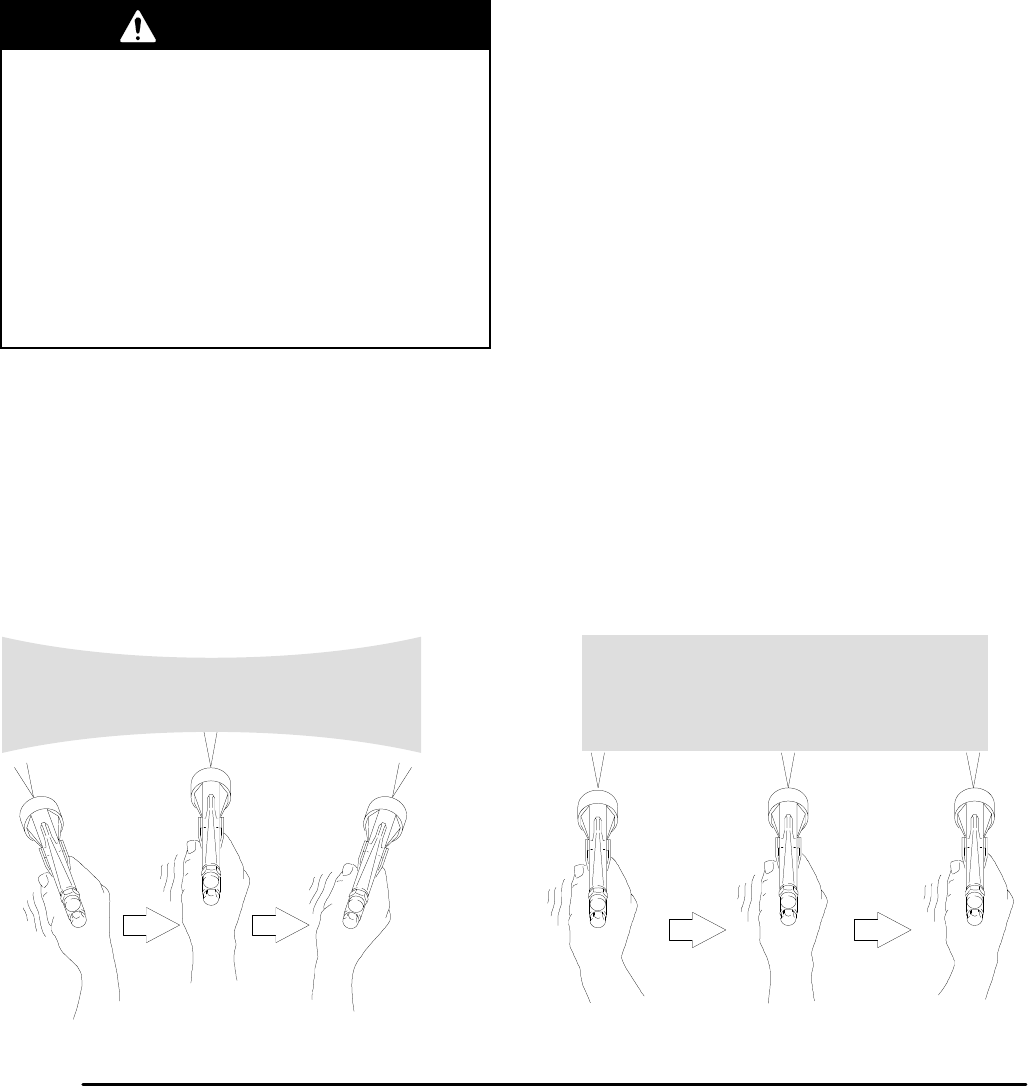

1. T

o achieve the best results when applying fluid,

keep the gun perpendicular to the surface and

maintain a consistent distance of approximately 6

to 8 inches (150 to 200 mm) from the object being

sprayed. See Fig. 14.

2. T

o obtain an even finish, use smooth, even strokes

across the object being sprayed with 50% overlap.

3.

Paint using parallel strokes. This spray gun applies

all coatings evenly without cross coating.

NOTE: T

o eliminate the need to shut of

f the air pres

-

sure at the air supply

, install a quick-disconnect at the

gun inlet fitting. See

Accessories.

WRONG RIGHT

Fig. 14

0793