18 308–293

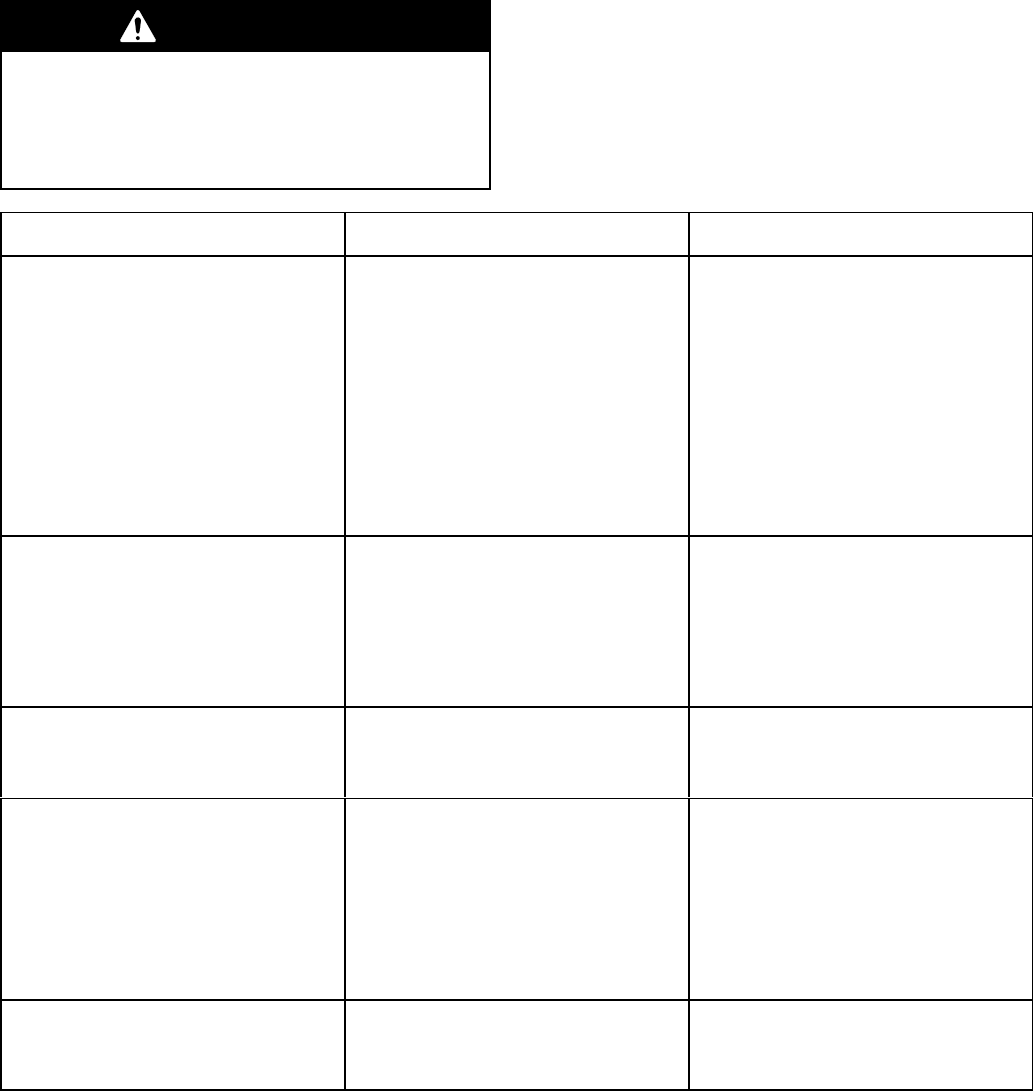

Troubleshooting

WARNING

PRESSURIZED EQUIPMENT HAZARD

T

o reduce the risk of a serious injury

, follow the

Pressure Relief Procedure

on page 13 before

checking or repairing any part of the gun or sys

-

tem.

PROBLEM CAUSE SOLUTION

Fluid flow is fluttering while spraying

1.

Fluid nozzle not tight enough

2.

Fluid filter clogged

3.

Fluid adjustment knob not

properly set

4. Baf

fle (item 1

1) installed wrong

or damaged

1. T

ighten fluid nozzle; Do not

exceed 35 in-lbs (4 N

Sm) torque.

2.

Check fluid filter

.

3. T

urn the fluid adjustment knob

out for less feathering or use a

larger size nozzle.

4.

Check if baf

fle protrusion is

properly inserted into gun insert

hole; see page 24. Replace

baf

fle if damaged.

Fluid flow fades while spraying high

viscosity fluids

1.

Air hose size is too restricted for

higher air flows

2.

Fluid pressure too low

, causing

fluid flow to reduce when gun is

elevated

1.

Use larger 3/8 in. (9.5 mm) ID

air hose, part no. 185–353. See

Accessories.

2.

Raise fluid pressure at source or

use a smaller fluid nozzle.

No round pattern control

Baf

fle (item 1

1) installed wrong or

damaged

Check if baf

fle protrusion is properly

inserted into gun insert hole; see

page 24. Replace baf

fle if damaged.

Pattern becomes of

f-set or heavy

on ends

1.

Fluid nozzle is over-tightened

2.

Air cap too tight

3.

Air cap horn holes plugged

1.

Do not exceed 35 in-lbs (4 N

Sm)

torque on nozzle. Replace

nozzle if damaged.

2.

Loosen air cap retaining ring.

3.

Clean air cap horn holes with

non-metallic item such as a

toothpick.

Fluid system will not operate at low

enough fluid pressure [below 10 psi

(70, kPa, 0.7 bar)]

There’

s no fluid regulator

, or air reg-

ulator on pressure pot is not sensi

-

tive enough at low pressures

Add low pressure fluid regulator

, or

add more sensitive air regulator on

pressure pot.