308–293 23

Service

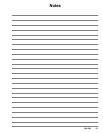

8. T

ighten the packing adjustment screw (31) with the

gun wrench (35), as shown in Fig. 10, until you can

feel a slight drag on the fluid needle. Do not over-

tighten the screw as this may bind the needle

movement.

Fig. 10

02104A

31

35

9.

Install the trigger (3). T

orque the screw (5) to

10–15 in-lbs (1.1–1.7 N

S

m). See Fig. 12.

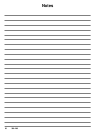

10. Remove

the

u-cup seal (32) from the fluid adjustment

nut (6). See Fig. 11. Be careful not to damage the

seal

surface or the nut’

s internal threads.

11.

Install the new u-cup seal (32) with the seal instal

-

lation tool (42); the u-cup lips must face toward the

tool as shown in Fig. 1

1. This will help apply even

pressure to the u-cup lips and avoid damaging

them.

12.

Push the u-cup seal (32) into the fluid adjustment

nut (6) until a definite snap is felt.

13.

Install the new packing ring (22).

Fig. 11

32

42

1

1

U-cup

lips

face

the

tool

02021

6

22

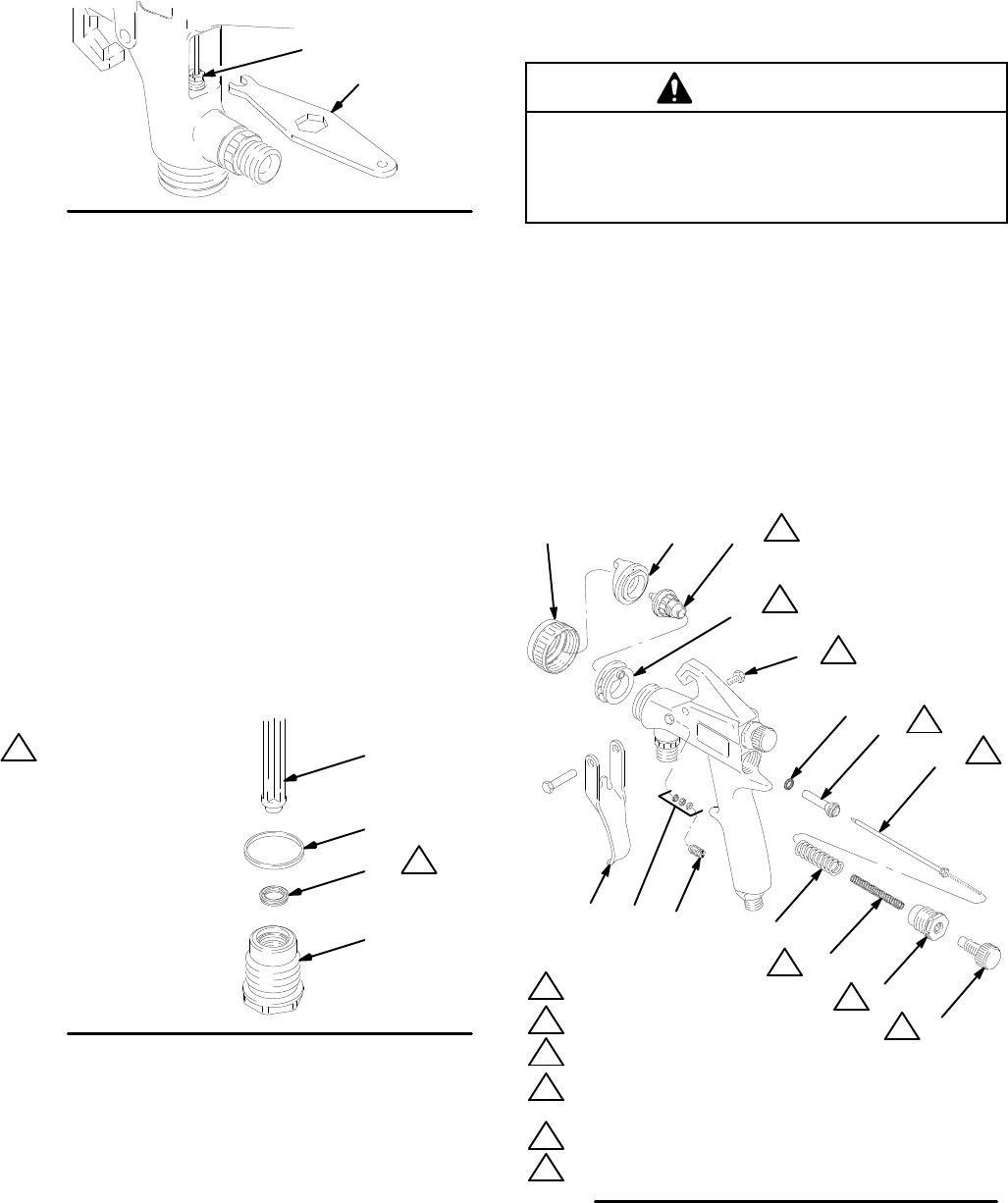

14. Install

the spring (15) and fluid adjustment nut (6).

T

orque the nut to 25–35 in-lbs (2.8–4.0 N

S

m). See

Fig. 12.

15. Install

the spring (16)

and fluid adjustment knob (8).

16. Trigger

the gun to test the needle movement. If the

needle does not return after the trigger is released

or is slow in returning, loosen the packing adjust

-

ment screw (31) with the gun wrench (35) until the

needle returns freely

. See Fig. 10.

17. T

rigger the gun while you install the fluid nozzle

(20) with the gun wrench (35).

CAUTION

When tightening the nozzle, do not exceed 40 in-lbs

(4.5 N

S

m) torque. Over-tightening the nozzle can

cause the nozzle hex to round, can af

fect the spray

pattern, and is unnecessary to guarantee a seal.

18.

Install the air cap ring (12) and air cap (19).

19.

Make sure the gun fluid packing assembly is

sealing properly by spraying solvent at low pres

-

sure before fully pressurizing the gun with the fluid

to be sprayed.

If the fluid packing leaks, tighten the packing

adjustment screw (31) slightly and retest until the

packing seals completely

.

Fig. 12

12 19 20

16

8

31

3

5

21

02103A

1

Lightly

lubricate

Lightly lubricate threads

T

orque to 35–40 in-lbs (3.9–4.5 N

Sm)

Be sure the baf

fle protrusion is properly inserted

into

the gun insert hole before tightening the nozzle

T

orque to 25–35 in-lb (2.8–4.0 N

Sm)

T

orque to 10–15 in-lb (1.1–1.7 N

Sm)

2

3

2

1

3

1

6

6

15

33

14

39

1

11

4

4

5

5

6