308–293

5

Selection

Charts

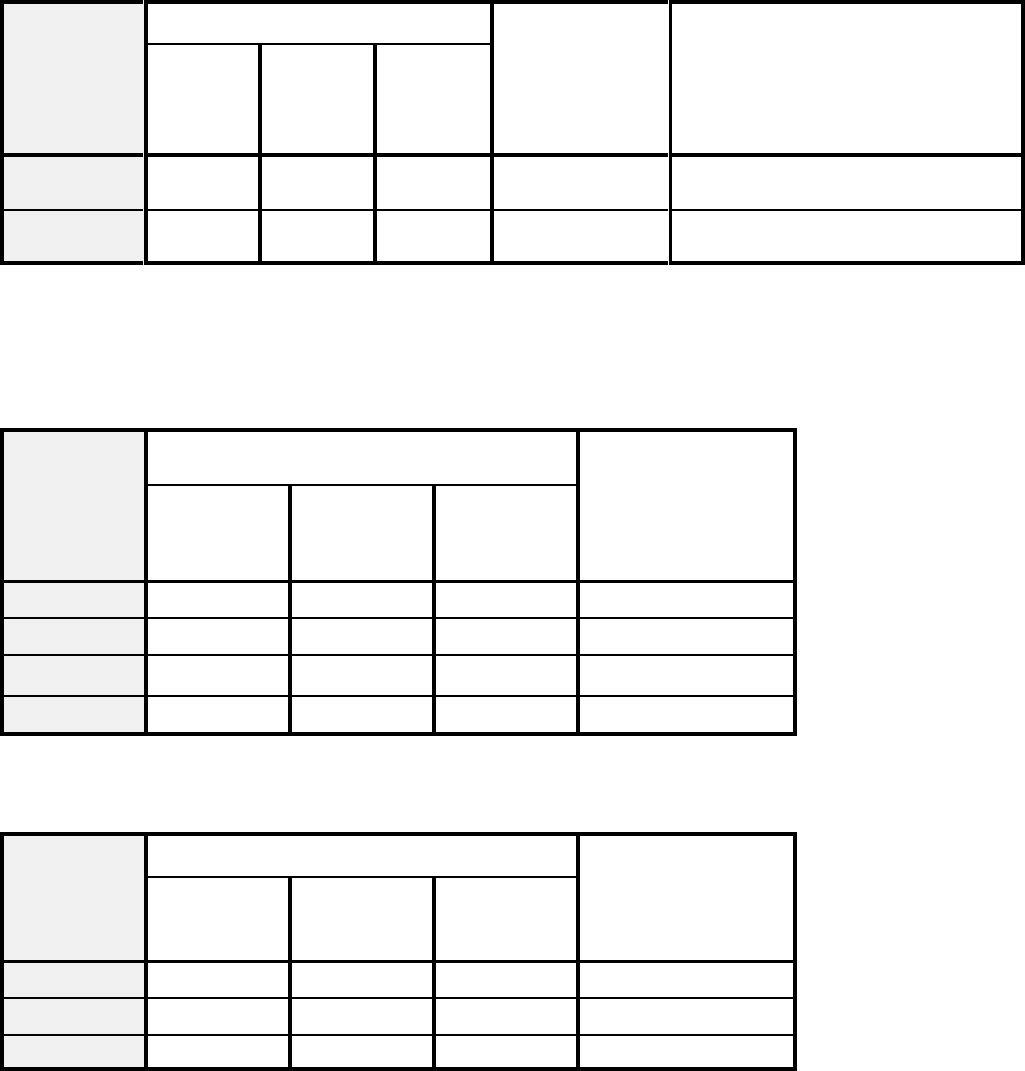

CHART 1: GUN ASSEMBLIES, Series B (continued)

Optional

Non-HVLP Compliant Gun Assemblies

With

standard needle and nozzle and optional high pressure air cap

Includes:

Optional

Complete

Gun

Assy

.

Part No.

Needle

Assy.

P/N

*

Nozzle

P/N

{ High

Pressure

Air Cap

P/N

Orifice Size

Material Usage

(See TERMS on page 4)

236–023 238–217 276–293 189–755 0.042”

(1.067 mm)

Light

to Medium Fluids or Low Fluid Flow

[5–8

oz./min. (0.15–0.24 l/min.)]

236–024 238–218 276–294 189–755

0.055” (1.397 mm)

Light to Medium Fluids or Medium Fluid

Flow

[6–12 oz./min. (0.18–0.36 l/min.)]

* Maximum

recommended torque to install molded fluid nozzle in the spray gun is 35 in-lbs (4 N

S

m).

{

See atomizing air pressure chart on page 7.

CHART 2: NEEDLE/NOZZLE/AIR CAP KITS

Standard

Needle/Nozzle/Air Cap Kits

Standard

Includes:

Standard

Needle/

Nozzle/Air

Cap Kit

Part No.

{ Needle

Assy.

P/N

*

Nozzle

P/N

Air Cap

P/N

Orifice Size

238–233 238–217 276–293 188–754 0.042”

(1.067 mm)

238–234 238–218 276–294 188–754

0.055” (1.397 mm)

238–235 238–219 276–295 188–755

0.070” (1.778 mm)

238–236 238–220 276–296 188–756

0.086” (2.184 mm)

{

See

page 6 for needle assembly replacement tips.

Optional

Needle/Nozzle/Air Cap Kits – available as “Build to Order”

Optional

Needle/

Includes:

Needle/

Nozzle/Air

Cap Kit

Part No.

{ Needle

Assy.

P/N

*

Nozzle

P/N

Air Cap

P/N

Orifice Size

235–306 238–703 276–290 188–754 0.020”

(0.508 mm)

235–307 238–703 276–291 188–754

0.026” (0.660 mm)

235–308 238–703 276–292 188–754

0.030” (0.762 mm)

* Maximum

recommended torque to install molded fluid nozzle in the spray gun is 35 in-lbs (4 N

S

m).

{

See page 6 for needle assembly replacement tips.