8

308–293

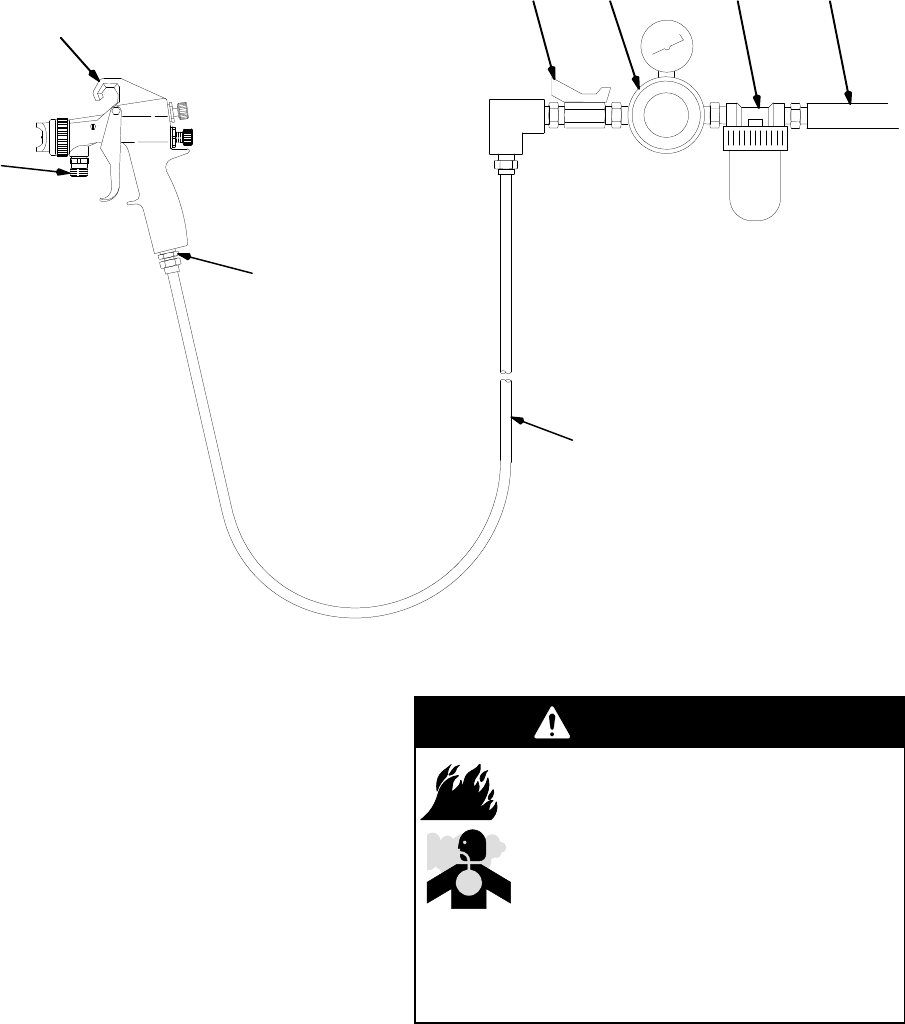

Typical

Installation

KEY

A Model

M-1265 Spray Gun

See page 4 for part numbers.

B

Fluid Inlet; 3/8 npsm (R3/8–19)

C

Air Inlet; 1/4 npsm

D

Air Hose

Recommend

5/16” (7.9 mm) ID hose

Optional

3/8” (9.5 mm) ID hose

E

Air Shut-of

f V

alve

F

Air Regulator

G

Air Filter

H

Air Supply Line

A

B

C

D

EF G

02018

NOTE:

See the

Accessories

section for

accessories recommended to install the system.

H

The M-1265 HVLP Spray Gun

The

Model M-1265 HVLP Spray Gun was designed to

produce the highest quality finish with today’

s fluids as

well as the the Low V

.O.C. (volatile organic compound)

fluids of tomorrow

.

This spray gun can spray most coatings or finishes

currently being used for automotive refinish, industrial,

aerospace, marine, wood, plastic and architectural

applications, while easily operating from any paint

delivery system, including cups, pressure pots, or

remote pumps for production line operation.

The Model M-1265 HVLP Spray Gun typically utilizes

65 psi (444 kPa, 4.4 bar) inbound air pressure to

produce high quality paint finishes at 10 psi (0.07 bar)

atomizing air pressure.

The air regulator must have a minimum air flow

capacity of 30 scfm at 100 psi (0.7 MPa, 7 bar) air

pressure.

NOTE:

If the gun’

s hanging hook is needed, remove

the gun trigger and replace the gun plate with the

hook, then reinstall the trigger

. See the parts drawing,

page 24.

Ventilate the Spray Booth

WARNING

To

prevent hazardous concentrations of

toxic and/or flammable vapors, spray

only in a properly ventilated spray booth.

Do not operate the spray gun unless

ventilation fans are operating.

Check and follow all of the National,

State and Local codes regarding air ex

-

haust velocity requirements.

Check and follow all local safety and fire codes.