15307741

Service

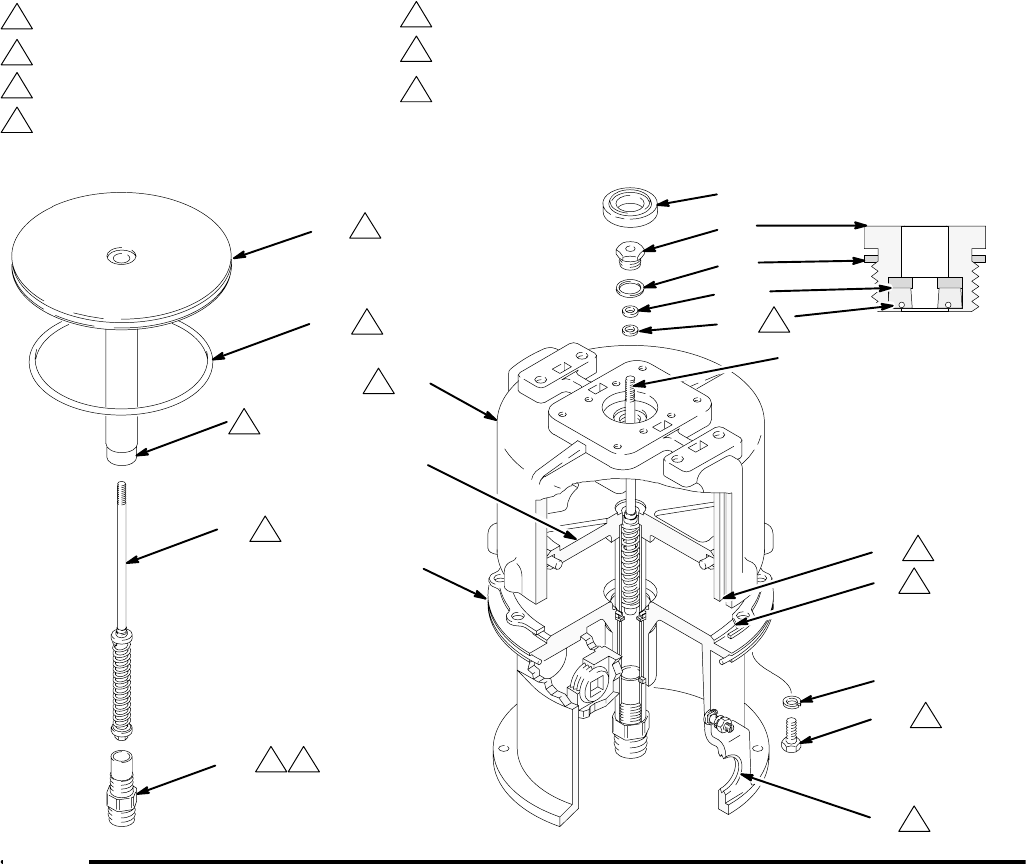

NOTE: Refer to Fig. 7 for steps 6 to 10.

6. Grease the trip rod (40) with light, water-proof

grease and slide it into the piston (34) shaft. Clean

the threads of the piston and the connecting rod

stud (39). Apply LoctiteR 242 or the equivalent to

both. Screw the stud into the piston and torque it

to 200–220 NSm (148–162 ft-lb).

7. Place the cylinder (36) upside down on the base

(47). Grease the piston (34), o-ring (33*), and

inside of the cylinder. Place the o-ring around the

piston; the o-ring is larger than the piston groove.

Install the piston in the cylinder so the excess of

the o-ring fits into one of the air channels (M) of

the cylinder. Use your fingers to push the o-ring

out of the channel and seat it in the piston groove.

Very carefully lower the piston into the cylinder.

8. Regrease the inside of the cylinder (36). Carefully

turn the piston assembly and cylinder over and

guide it into the base (47). Align one of the cylin-

der’s air channels (M) with the notch (K) in the

gasket (35) and with the optional fluid outlet (L) of

the base. Install the lockwashers (13) and screws

(31) and torque to 34 NSm (25 ft-lb).

9. Install the backup washer (64*) and v-block pack-

ing (65*) in the bearing (37) so the lips of the

packing face out of the bearing. Install the gasket

(66) on the bearing. Grease the trip rod (40) and

thread the bearing onto the trip rod and into the

cylinder (36). Use a 1 in. deep-well socket wrench

to tighten the bearing.

10. Install the rubber pad (8) in the cylinder (36).

Fig. 7

1

3

4

2

Grease with light, waterproof grease.

Align air channel (M) and notch (K) in gasket (35)

with the optional fluid outlet (L) in the base (47).

Apply Loctiter 242 or equivalent to threads.

Torque to 200–220 NSm (148–162 ft-lb).

Grease inside wall of cylinder.

5

6

7

Torque to 34 NSm (25 ft–lb).

Lips must face down, out of bearing (37).

07283A

8

37

66

64*

65*

36

13

31

34

47

40

03701

40

39

34

33*

M

K

L

1

2

2

3

1

1

4

5

6

7

7

7