Troubleshooting

30 309856P

Troubleshooting

1. Follow Pressure Relief Procedure, page 18,

before checking or repairing gun.

2. Check all possible problems and causes before

disassembling gun.

CAUTION

To prevent cross-contamination of the gun’s wetted

parts, do not interchange A component (isocyanate)

and B component (resin) parts.

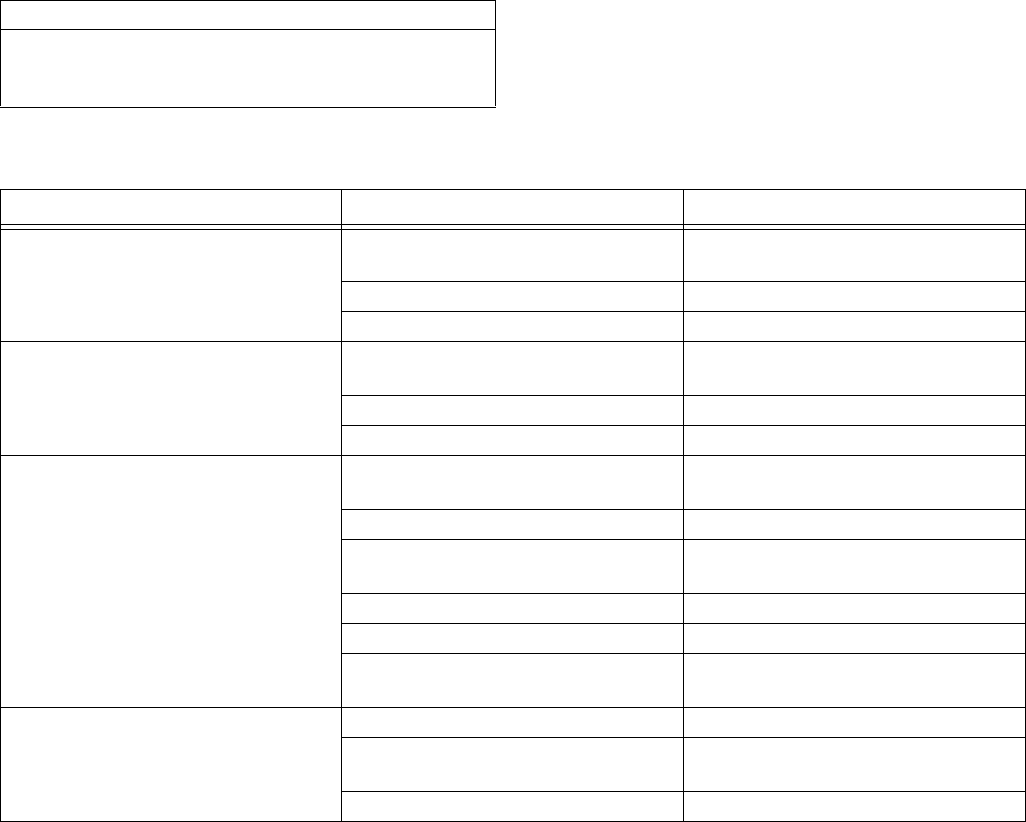

PROBLEM CAUSE SOLUTION

Gun does not fully actuate when trig-

gered.

Piston safety lock engaged. Disengage piston safety lock, page

12.

Plugged muffler (22). Clean, page 22.

Damaged air valve o-rings (24). Replace, page 44.

Fluid does not spray when gun is fully

actuated.

Closed fluid valves (12b). Open.

Plugged impingement ports. Clean, page 23.

Plugged check valves (36). Clean, page 41.

Gun actuates slowly or with delayed

action.

Plugged muffler (22). Clean, page 22.

Damaged piston o-rings (16, 19). Replace, page 42.

Dirty air valve, or damaged o-rings

(24).

Clean air valve or replace o-rings,

page 44.

Mix module nut (25) too tight. Loosen nut, then retighten, page 37.

Incorrect purge rod adjustment. Adjust Purge Rod, page 15.

Loose lock ring (11). Tighten, use tool if necessary. Adjust

Purge Rod, page 15.

Purge rod will not actuate. No air pressure. Connect air supply.

Low air pressure. Set air pressure above 80 psi (0.56

MPa, 5.6 bar).

Buildup on purge rod (31). See Clean Purge Rod, page 27.