12

307-712

MAINTENANCE

To

C

lea

n o

r C

hang

e A

i

r C

a

p a

n

d F

lui

d N

ozzle

CAUTION

Do

not use metal tools to clean the air cap holes as

this may scratch them, and make sure the elec-

trode

wire is not damaged. Scratches in

the air cap

holes

or a damaged electrode wire can distort the

spray

pattern.

Equipment needed:

Soft bristle brush (supplied).

Fluid nozzle wrench (supplied).

Solvent compatible with fluid being sprayed.

Procedure:

1. Follow

the

Pressure Relief Procedure W

arning

on

page

9.

2.

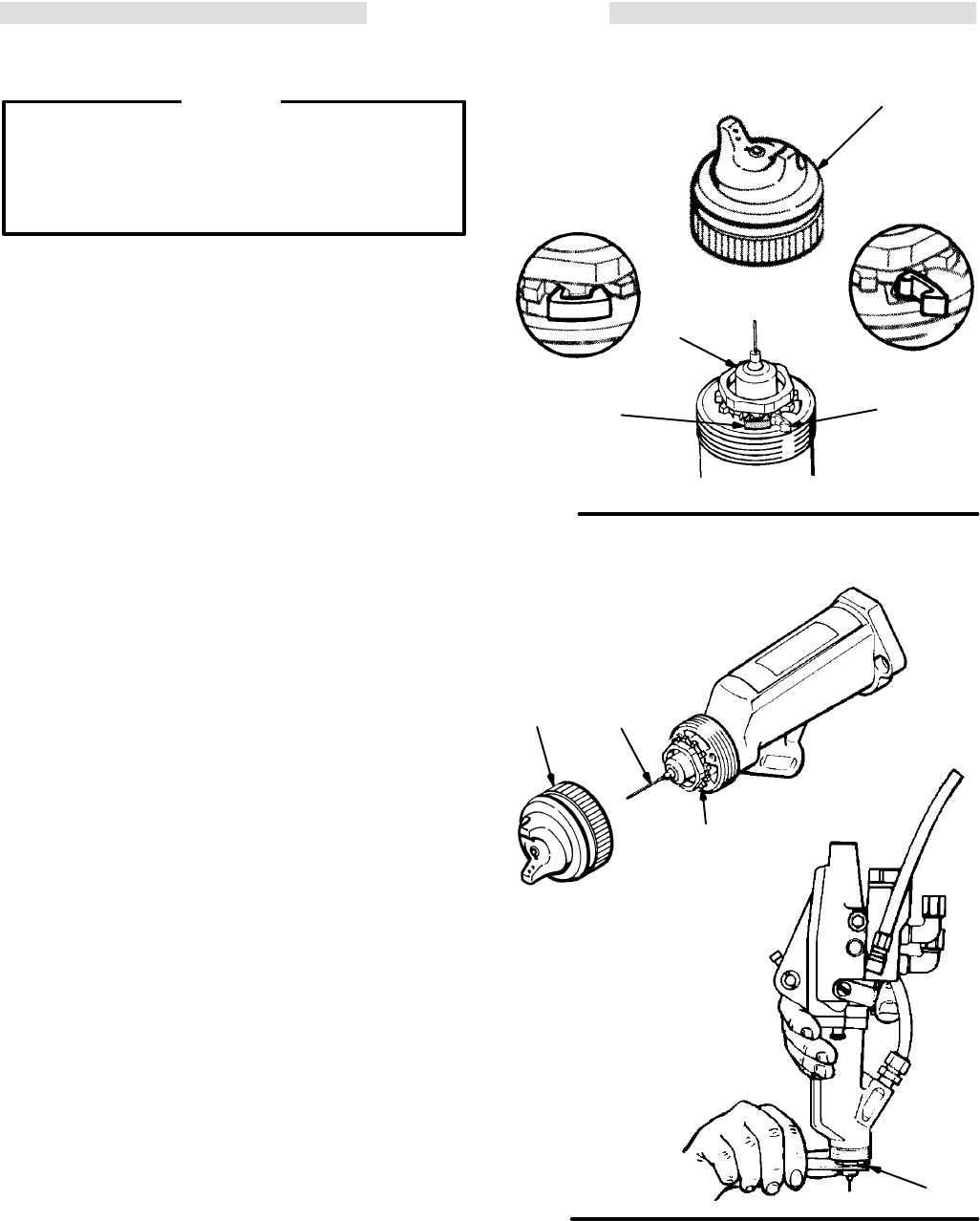

Remove the air cap assembly (BB). See Fig 6.

3. T

urn the locking pin (81) to the unlocked position.

4. Squeeze

the gun trigger and remove the fluid nozzle

(15) with the fluid nozzle wrench (66g) supplied.

Make

sure the front of the gun is pointed down. See

Fig

6.

5. Use

the soft bristle

brush (66a) supplied and solvent

to

clean the air cap, fluid nozzle, and front part of the

gun.

6. Squeeze the gun trigger and screw the fluid nozzle

back into the gun. Tighten the nozzle securely with

the

wrench (66g) supplied. T

orque the fluid nozzle to

1.1–1.4

N

S

m (10–12

in–lb). See Fig 6. T

urn the lock

-

ing

pin to the locked position.

7. Carefully

reinstall the air cap assembly

. A

void bend

-

ing

the electrode (CC).

8. Tighten

the retaining nut so it is snug. If the nut is

tight

enough,

you will feel resistance when turning the air

cap.

If too tight, the spray pattern will be distorted.

Fig 5

KEY

15 Fluid

Nozzle

BB

Air Cap Assembly

81

Locking Pin

BB

15

Locked

Position

Unlocked

Position

DETAIL

DETAIL

81

81

Fig

6

KEY

CC Electrode

15 Fluid

Nozzle

16

Air Cap Assembly

66g Wrench

CC

15

16

T

orque to

1.1–1.4 N

Sm

(10–12 in–lb)

66g