18 308584

Operation

Operating the Spray Gun

WARNING

FIRE AND EXPLOSION HAZARD

To reduce the risk of fire and explosion,

only use this equipment to spray non-

flammable, waterborne fluids as defined

on the front cover of this manual.

WARNING

ELECTRIC SHOCK HAZARD

Contact with the charged components of

the spray gun will cause an electric

shock. Do not touch the gun nozzle or

electrode or come within 4 inches (101.6 mm) of

the front of the gun during gun operation or until

after following the Fluid Voltage Discharge and

Grounding Procedure on page 16.

Follow the Fluid Voltage Discharge and Ground-

ing Procedure on page 16 when you stop spray-

ing and whenever you are instructed to discharge

the voltage.

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of an injury, follow the Pressure

Relief Procedure on page 16 when you stop

spraying, before installing or cleaning the fluid

nozzle, and whenever you are instructed to relieve

the pressure.

WARNING

COMPONENT RUPTURE HAZARD

To reduce the risk of component rupture,

which can cause serious injury, do not

exceed the maximum working pressure

of the lowest rated system component. This equip-

ment has a 100 psi (0.7 MPa, 7 bar) maximum

working air and fluid pressure.

Follow the steps below to establish the correct fluid

flow and air flow. Do not turn the ES ON-OFF lever to

ON yet:

1. Follow the Operating Checklist on page 17.

2. Make sure the system voltage is discharged.

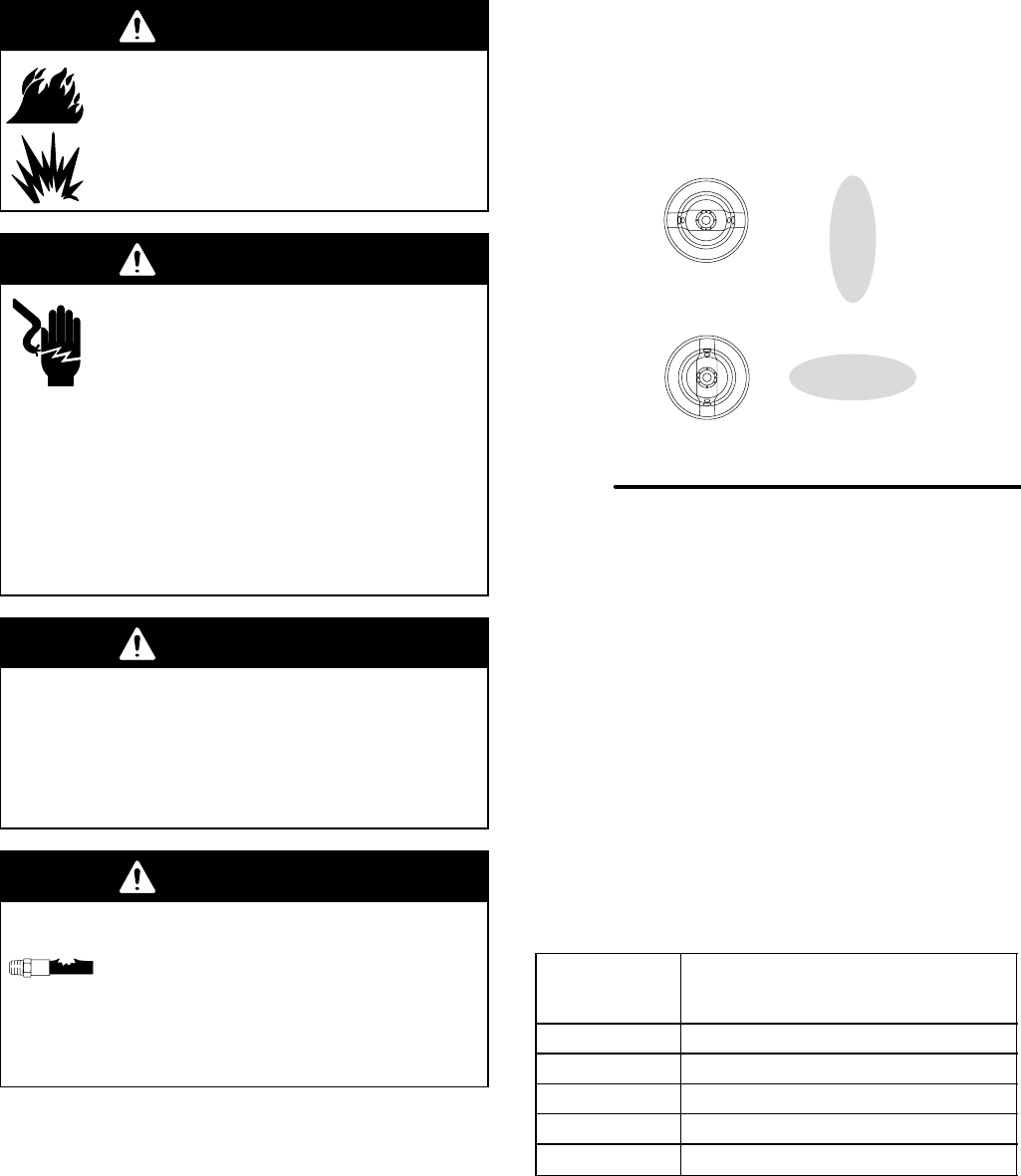

Loosen the air cap retaining nut, and rotate the air

cap for a vertical or horizontal spray pattern. See

Fig. 9. Then tighten the retaining nut until the air

cap is held firmly in place; you should not be able

to rotate the air cap horns by hand.

Fig. 9

02020

Horizontal Pattern

Vertical Pattern

3. Pressurize the fluid supply, and adjust the fluid

flow by using the fluid pressure regulator installed

in the fluid line. Refer to instruction manual 307803

to set the fluid pressure for various fluid flows,

according to the size of the fluid nozzle being

used.

4. If necessary, further adjust the fluid flow rate with

the fluid adjustment knob (J). See Fig. 10.

5. Fully open the fan air valve (P).

6. Set the air pressure with the air pressure regulator.

The following chart shows the air hose inlet pres-

sure required to get full voltage from the power

supply. To avoid shortening the turbine life, do not

exceed the recommended air pressures.

Air Hose

Length

ft. (m)

Dynamic pressure at air hose inlet

required for full voltage

psi (kPa, bar)

15 (4.6) 45 to 50 (314 to 345, 3.1 to 3.4)

25 (7.6) 50 to 55 (345 to 379, 3.4 to 3.7)

50 (15.3) 60 to 65 (410 to 444, 4.1 to 4.4)

75 (22.9) 68 to 73 (465 to 501, 4.5 to 5.0)

100 (30.5) 75 to 80 (514 to 550, 5.1 to 5.5)