24 308584

Troubleshooting

Voltage Loss Troubleshooting (continued)

11. A dielectric breakdown is most likely in one of the

following three areas. Repair or replace the com-

ponent that is failing.

D Fluid hose

Check for leakage or any bulges in the outer

jacket, which may indicate a pin-hole leak

through the PTFE layer. Disconnect the fluid

hose from the gun, and look for signs of fluid

contamination on the outside of the PTFE

portion of the fluid tube.

Inspect the end of the hose connected to the

voltage block. Look for cuts or nicks.

Make sure the hose is properly stripped; see

Fig. 4, page 12, for hose stripping dimensions.

Restrip or replace the hose.

D Fluid packings

Remove the packing assembly from the gun

as instructed on page 33, and look for signs of

fluid leakage or any blackened areas, which

would indicate arcing is occurring along the

packing rod.

D Fluid hose connection joint to the spray gun

A breakdown at the fluid hose connection joint

would be caused by fluid leaking past the

o-ring seals on the end of the hose. Remove

the hose at the gun connection and look for

signs of fluid leakage along the PTFE tube.

12. Before reassembling the gun, clean and dry the

gun fluid inlet tube (item 75 on page 46). Repack

the inner spacer of the fluid packing rod with

dielectric grease and reassemble the gun as

instructed on page 34.

13. Reconnect the fluid hose as instructed on page 12.

14. Check the gun voltage with the voltage probe and

meter before filling the gun with fluid.

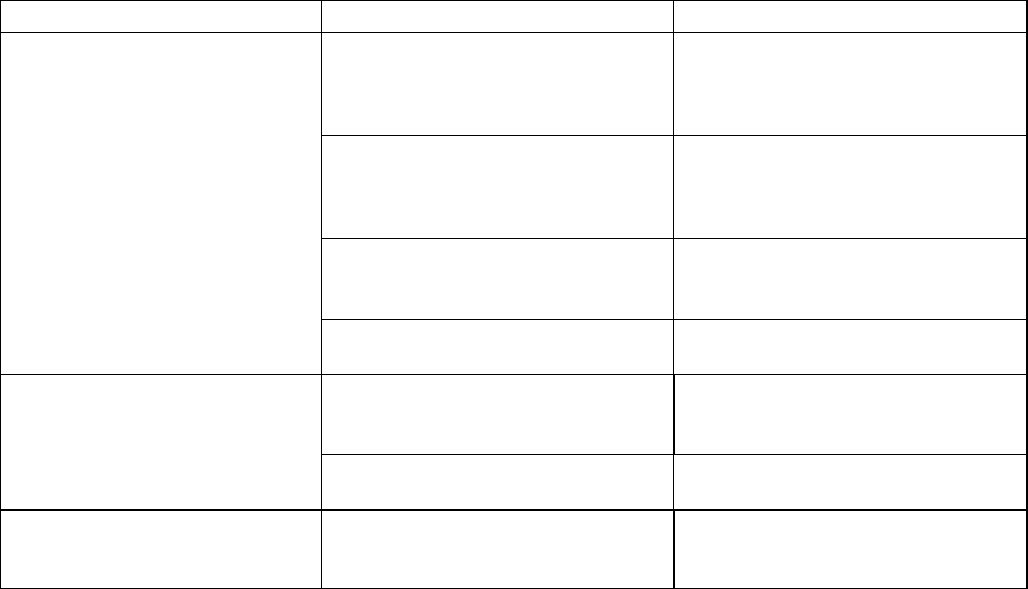

Electrical Troubleshooting

Problem Cause Solution

Voltage is still present at the gun

after following the Fluid Voltage

Discharge and Grounding Pro-

cedure

Gun electrostatics (gun ES lever) are

not turned off.

Turn off the gun electrostatics.

Did not wait long enough for the volt-

age to discharge through the voltage

bleed resistor.

Wait a longer period of time before

touching the electrode with a

grounded rod. Check for possible

bleed resistor failure.

There is an air pocket in the fluid line

that leaves the fluid near the gun

isolated.

Determine the cause of the air pocket

and fix the problem. Purge the air out

of the fluid line.

Voltage isolation system failed. See the isolation system manual for

service information.

The operator gets a shock The operator is not properly grounded

or is near an ungrounded object.

Be sure the floor and the operator are

properly grounded; see Ground the

System, page 14.

The gun is not properly grounded. See Check the Electrical Ground-

ing, page 15.

The operator gets a shock when

touching the workpiece

The workpiece is not properly

grounded.

Clean the workpiece hangers; check

for proper grounding on the conveyor

or track