308584 27

Troubleshooting

Gun Operation Troubleshooting (continued)

Excessive spray fog

The air pressure is too high. Reduce the air cap air pressure by

closing the atomizing air valve more

or decreasing the gun air inlet pres-

sure; use the least air pressure

needed for good results. Do not re-

duce below minimum pressure need-

ed for full voltage. See page 18.

The fluid is thinned too much. Properly thin the fluid.

No fluid sprays from the gun

The fluid supply is low. Check the fluid supply; add fluid if

necessary.

The fluid nozzle is dirty or clogged. Clean the fluid nozzle; see page 21.

The fluid nozzle is damaged. Replace the fluid nozzle; see page

30.

The equipment is covered with

fluid

The exhaust air flow is insufficient or

not directed properly.

Check for the proper CFM; check the

baffles and direction of the air flow.

The distance between the gun and

workpiece is incorrect.

Adjust the spraying distance to 8 to

12 inches (203 to 305 mm).

Dirty air cap

The electrode is bent. Straighten the electrode.

The nozzle orifice is damaged. Replace the fluid nozzle; see page

30.

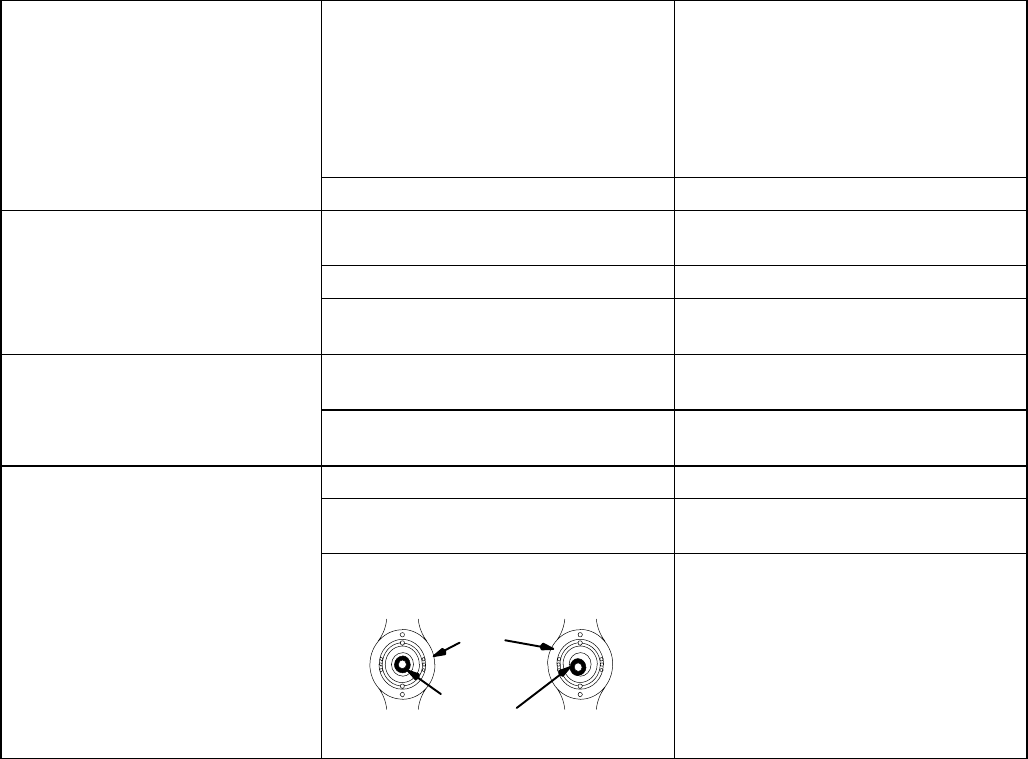

The air cap and fluid nozzle are mis-

aligned.

ALIGNED

Fluid

Nozzle

Air

Cap

MISALIGNED

Check the air cap and fluid nozzle

seat for fluid buildup. Clean or

replace parts as needed; see page 21

or 30.