28 308584

Electrical Tests

WARNING

ELECTRIC SHOCK HAZARD

Follow the Fluid Voltage Discharge

and Grounding Procedure on page 16

before checking or servicing and when-

ever you are instructed to discharge the voltage to

ensure the voltage is discharged and avoid serious

injury from an electric shock.

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of an injury, follow the Pressure

Relief Procedure on page 16 before checking or

servicing the gun and whenever you are instructed

to relieve the pressure.

WARNING

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

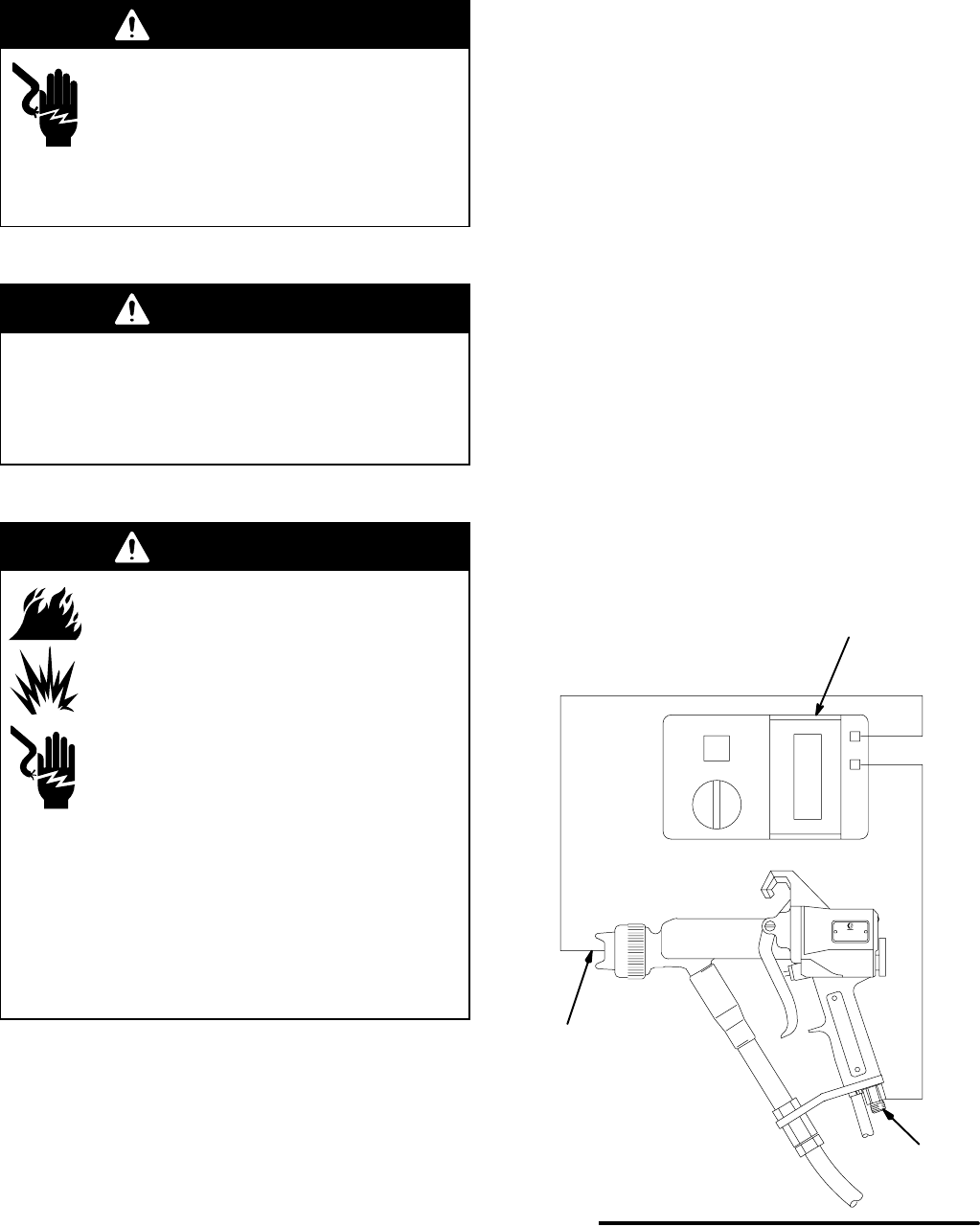

Megohmmeter P/N 218979 (A-see Fig.

13) is not approved for use in a hazard-

ous area. To reduce the risk of sparking,

do not use the megohmmeter to do

electrical tests unless:

D The gun has been removed from the

hazardous area;

D Or all spraying devices in the hazardous area

are turned off, ventilation fans in the hazardous

area are operating, and there are no flammable

vapors in the area (such as open solvent con-

tainers or fumes from spraying).

Failure to follow this warning could cause fire,

explosion, electric shock and result in serious injury

and property damage.

The performance and safety of the spray gun are

directly affected by the condition of the electrical

components contained inside the gun. The electrical

tests can be used to determine the condition of the

power supply (18) and the resistor stud (22) as well as

the continuity of the electrical path between the com-

ponents.

Use the megohmmeter (A), part no. 218979, and an

applied voltage of 500 volts to complete these

electrical tests. Connect the leads as shown.

Test Gun Resistance

NOTE: The fluid passage must be flushed and dried

to get an accurate reading. Check the resistance with

the gun triggered and untriggered.

1. Prepare the gun for service as instructed on

page 30.

2. Measure the resistance between the end of the

gun electrode (20) and the air inlet fitting (17). See

Fig. 13.

3. The resistance should be between 180 to 220

megohms. If the resistance is outside the specified

range, go to the next test.

4. If you still have problems, refer to Voltage Loss

Troubleshooting, page 22, for other possible

causes of poor performance, or contact the near-

est authorized service agency.

Fig. 13

17

20

A

KEY-Fig. 13

A Megohmmeter

17 Air Inlet Fitting

20 Electrode

5153B

Continued on the next page.