36 308584

Service

Fluid Adjustment Assembly Repair

(continued)

5. To remove the sleeve (45d), hold the cap (45c)

and turn the sleeve stop (45e) counterclockwise

with a pliers.

6. Remove the stem (45a) and o-ring (45b).

7. Repair or replace any damaged parts. Lubricate

the o-ring (45b).

8. Carefully apply low strength (purple) Loctiter or

equivalent thread sealant to the sleeve (45d)

external threads. Turn the sleeve in with the sleeve

stop (45e) until it is bottomed out, then back it out

1/8 turn.

CAUTION

Do not allow Loctite to get onto the stem (45a) during

assembly or the stem will not turn.

9. Place the fluid adjustment assembly on the work-

bench with its threaded end facing down and allow

the Loctite to cure over night.

10. After the Loctite has cured, assemble the fluid

adjustment assembly into the gun.

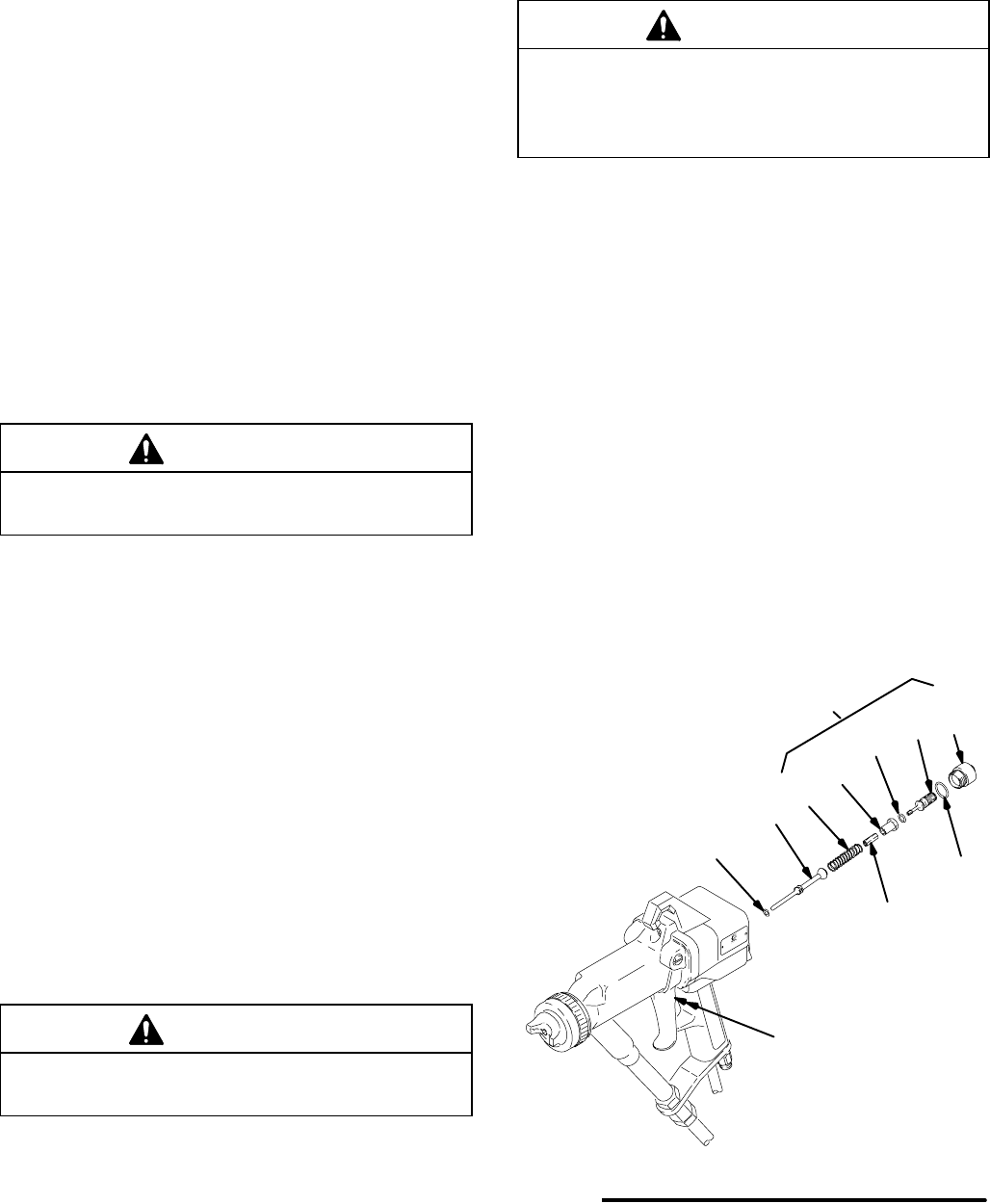

Air Trigger Valve Repair

1. Prepare the gun for service as instructed on

page 30.

2. Using a 14 mm socket wrench, remove the fluid

adjustment assembly (45), o-ring (23), and spring

(44). See Fig. 22.

3. Loosen the air valve packing nut (40) one full turn.

Remove the air valve shaft (39) with a pliers.

CAUTION

When removing the air valve shaft (39), be careful

not to damage the seat area.

4. Check the o-rings (41, 23) for damage and replace

them if necessary. Apply a very light coat of

petroleum jelly to the o-rings.

CAUTION

Do not over-lubricate parts. Excessive lubricant on

the o-ring (41) and air valve shaft (39) can be pushed

into the gun air passage and blemish the finish on

the workpiece.

5. Unscrew the packing nut (40) to check the u-cup

(42). Do not remove the u-cup unless it is dam-

aged.

6. Install the air valve shaft (39), with the o-ring (41),

and spring (44) into the back of the gun handle (7).

If the u-cup (42) was removed, install the air valve

shaft (39) before installing the u-cup. Install the

u-cup with its lips facing into the gun handle.

7. Install the fluid adjustment knob (45), with the

o-ring (23). Tighten the cap with a screw driver.

Tighten the air valve packing nut (40) until it bot-

toms.

Fig. 22

41

39

44

23

45a

40, 42

45e

45d

45b

45c

45

Apply a very light coat of lubricant to the o-rings (41, 23).

Carefully apply low strength (purple) Loctite or equivalent to

sleeve (45d) external thread. Turn sleeve in with sleeve stop

(45e) until it bottoms out, then back out 1/8 turn. Allow Loctite to

cure overnight.

Do not remove u-cup (42) unless damaged. Install with lips

facing into handle. Tighten packing nut (40) until it bottoms.

05162B