308584 41

Service

Turbine Alternator Replacement

NOTE: Replace turbine bearings after 2,000 hours of

operation. See your authorized Graco representative.

1. Prepare the gun for service as instructed on

page 30.

2. Remove the barrel as instructed on page 39.

3. Remove the power supply as instructed on

page 40.

4. Squeeze the two ends of the retaining ring (35)

together, and carefully pull the alternator (37) away

from the power supply (18) until the connector (V)

disengages. See Fig. 27, page 40.

5. Use an ohmmeter to test the turbine alternator coil.

Measure the resistance between the two outer

terminals of the 3-wire connector (V). The

resistance should be 3 to 5 ohms. If the resis-

tance varies from this value, replace the alternator.

6. Measure the resistance between each outer

terminal of the 3-wire connector (V) and the turbine

alternator (37) housing. The resistance should be

infinite. If the resistance is not infinite, replace the

alternator.

7. Connect the 3-wire connector (V) to the 3 prongs

in the power supply (18). Push the alternator (37)

onto the power supply until the retaining ring (35)

engages with the alternator.

8. Install the power supply in the gun handle as

instructed on page 40.

9. Install the barrel on the handle as instructed below.

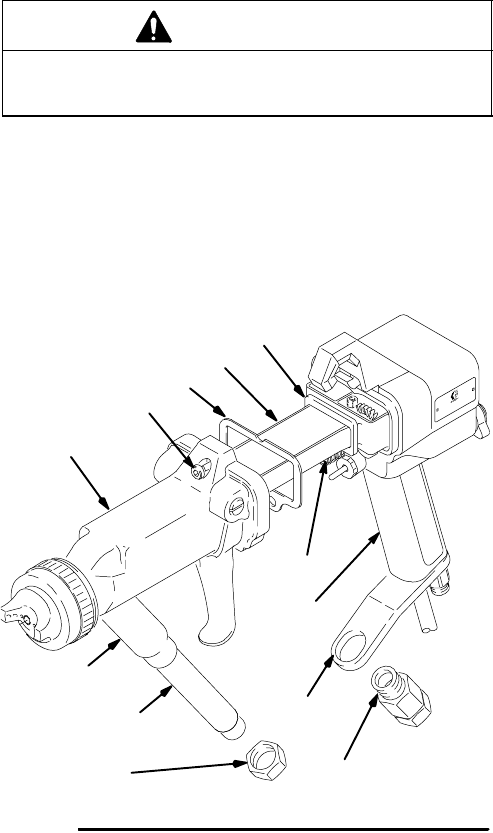

Barrel Installation

1. Clean and dry the inside of the fluid inlet tube (75).

See Fig. 28.

2. Be sure the gaskets (34, 18a) and spring (30) are

in place. Replace the parts if they are damaged.

3. Place the barrel (3) over the power supply (18) and

onto the gun handle (7). Make sure the fluid nee-

dle spring (30) is seated properly, and align the

fluid inlet tube (75) with the bracket port. Slide the

nut (78) onto the end of the fluid inlet tube.

4. Tighten the three screws (5) oppositely and evenly

with the ball-end wrench (63). Tighten the cap

screws to 18 in-lbs (2 NSm) maximum (about a half

turn past snug). Do not over-tighten the screws.

CAUTION

To avoid damaging the gun, do not over-tighten the

screws (5).

5. Install the ferrule housing (79) through the gun

bracket (76), and secure it with the nut (78).

6. Test the gun resistance as instructed on page 28.

Fig. 28

18a

18

34

5

3

30

7

75

78

79

76

Tighten the screws (5) to 18 in-lbs (2 NSm) maximum (about half

turn past snug), using the wrench (63) provided..

91

05158B