Model G0740 (Mfg. Since 11/12)

-79-

The clamping pressure of the half nut is fully

adjustable with a gib that can be loosened or tight-

ened by two set screws. Use this procedure to

adjust the half nut if it becomes loose from wear,

or it is too tight for your preferences. A half nut that

is too loose will make it difficult to produce accu-

rate work. A half nut that is too tight will increase

the rate of wear on itself and the leadscrew.

Tool Needed: Qty

Hex Wrench 3mm .............................................. 1

To adjust the half nut:

1. DISCONNECT LATHE FROM POWER!

2. Disengage the half nut, then remove the

thread dial.

3. Turn the two set screws (see Figure 121)

clockwise to tighten the half nut and counter-

clockwise to loosen it. Make sure to turn the

set screws in even amounts so that one end

of the gib does not become tighter than the

other.

V-belts stretch and wear with use, so check the

tension on a monthly basis to ensure optimal

power transmission. Replace all of the V-belts as

a matched set if any of them show signs of glaz-

ing, fraying, or cracking.

Tools Needed: Qty

Phillips Screwdriver #2 ...................................... 1

Open End Wrench 24mm .................................. 1

To adjust the V-belts:

1. DISCONNECT LATHE FROM POWER!

2. Remove the end gear cover, the motor

access panel, and the rear access panel to

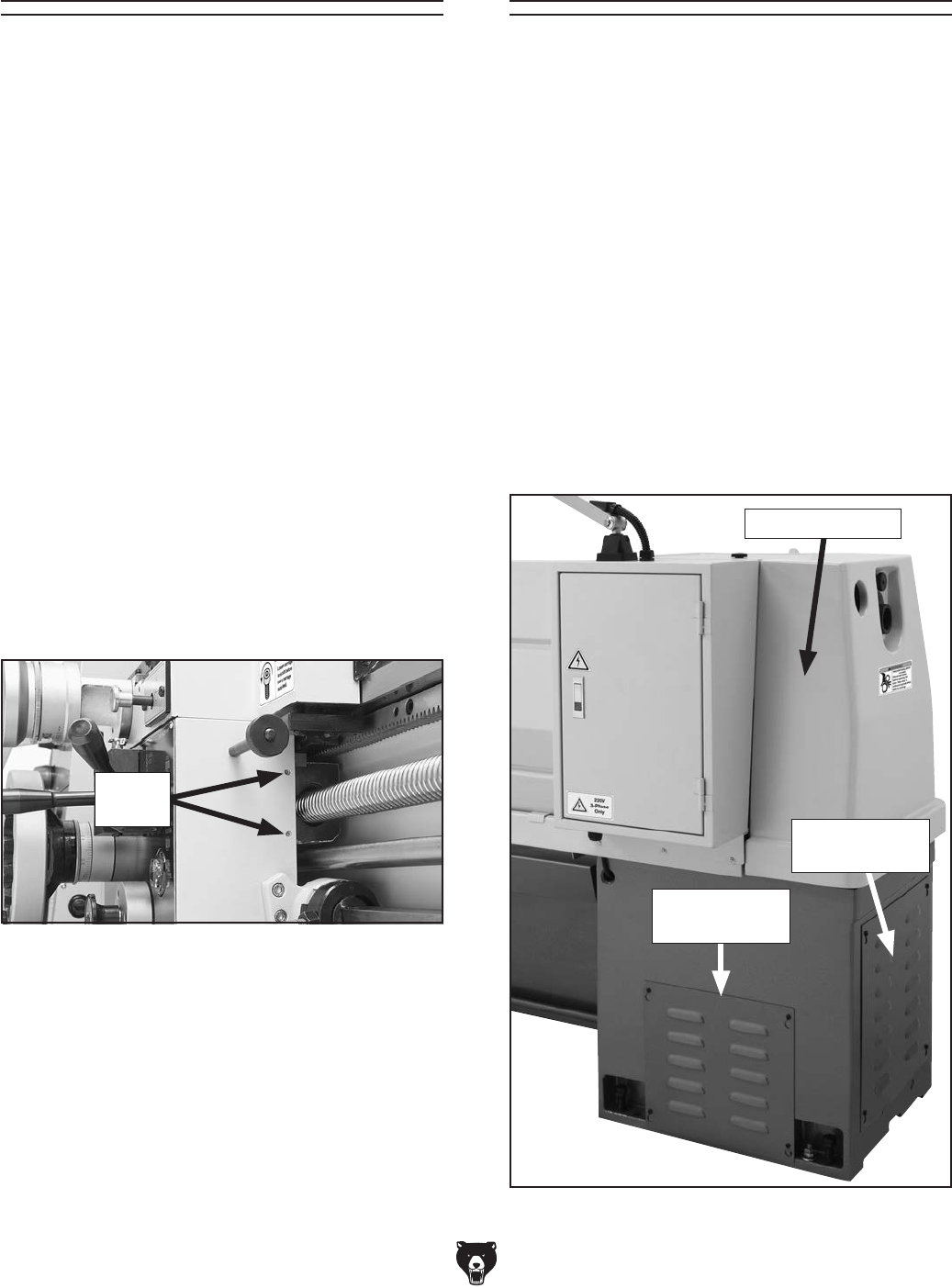

expose the V-belts, pulleys, and motor (see

Figure 122).

V-BeltsHalf Nut Adjustment

4. Engage/disengage the half nut several times

and notice how it feels. The half nut is cor-

rectly adjusted when it has a slight drag while

opening and closing. The movement should

not be too stiff or too sloppy.

5. Repeat Steps 3–4, if necessary, until you are

satisfied with the half nut pressure.

6. Re-install the thread dial.

Figure 121. Half nut gib adjustment.

Set

Screws

Figure 122. End gear cover and access panels.

Motor Access

Panel

Rear Access

Panel

End Gear Cover