SKU 95668 For technical questions, please call 1-800-444-3353 PAGE 24

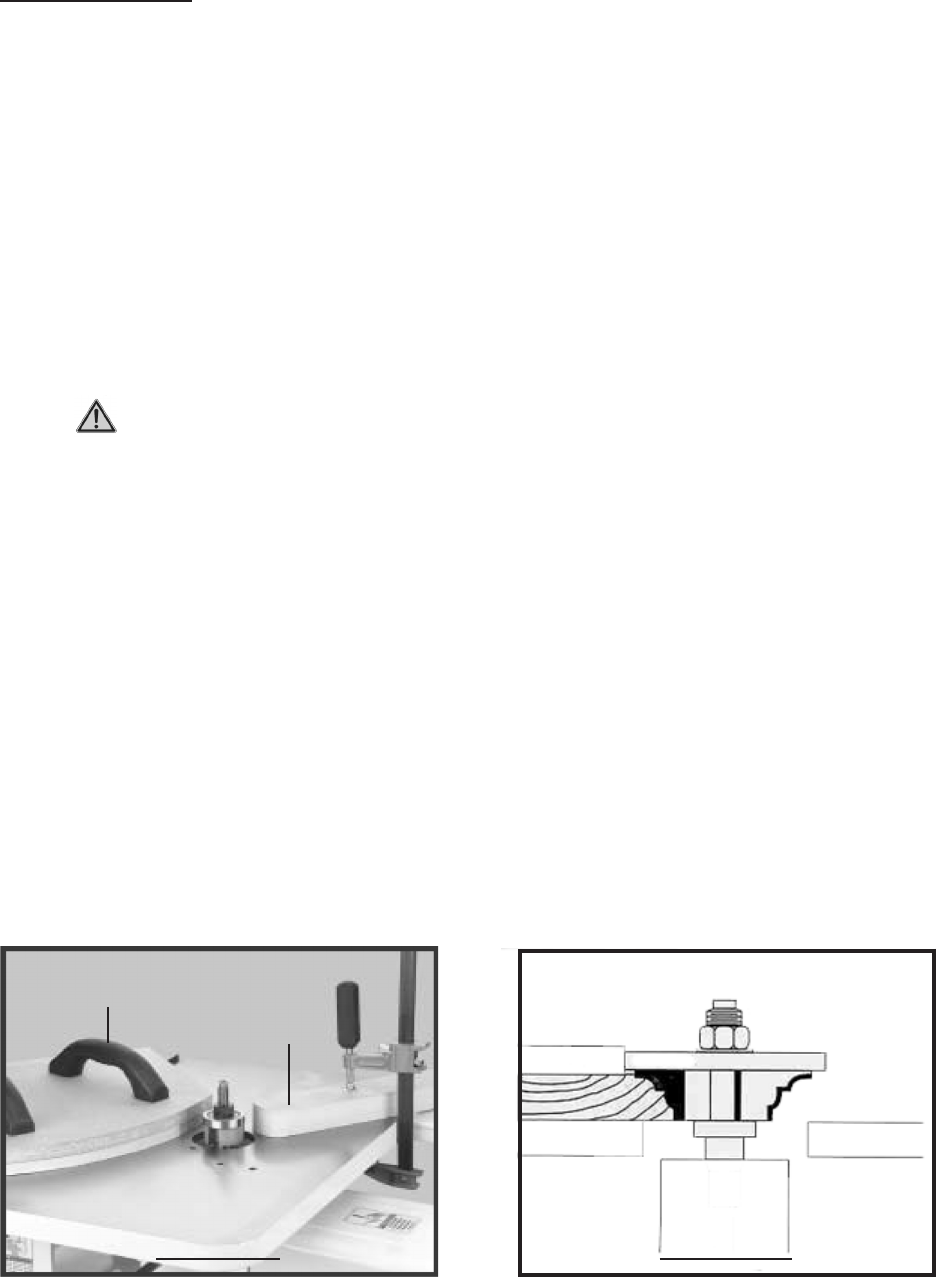

Pattern Shaping:

1. Sometimes the location of the Taper Pin (56) holes on the Work Table (52) will

not always be in the safest position. You can clamp a piece of scrap wood to the

Work Table so the edge of the scrap wood can be used as the starting support.

(See Figure JJ.)

2. The use of patterns (templates) allows identical parts to be cut with speed and

accuracy. Shaping with a pattern begins by attaching a prefabricated template to

the rough workpiece. The edge of the template rides against a Rub Collar (98,

99, 100) on the Spindle (105) as the Cutter cuts the matching prole on the

workpiece edge. Also, you can incorporate extra features into the template

assembly (such as toggle clamps - not included) to hold the workpiece or you

can use custom guards for safety and protection. (See Figure KK.)

CAUTION! Make sure to design jigs and xtures so screws and clamps DO

NOT contact the Cutter and the workpiece is held securely to the jig. The jig

must be stable on the Work Table (52).

3. To make a template, design the assembly so that cutting will occur underneath

the workpiece. Make sure screws or clamps will not come into contact with the

Cutter.

4. Make handles for safety and control.

5. Use materials that will move easily across the Work Table (52) surface and Rub

Collar (98, 99, 100).

6. Remember to consider the Cutter and Rub Collar (98, 99, 100) diameter when

making the pattern.

7. Install hold-down clamps (not included) at three sides of the pattern assembly, or

screw the pattern assembly to the back side of the workpiece.

SCRAP WOOD

PUSH BLOCK

(NOT INCLUDED)

TEMPLATE

RUB COLLAR (98, 99, 100)

FIGURE JJ FIGURE KK