HERO Operator’s Manual – Page 19 of 23

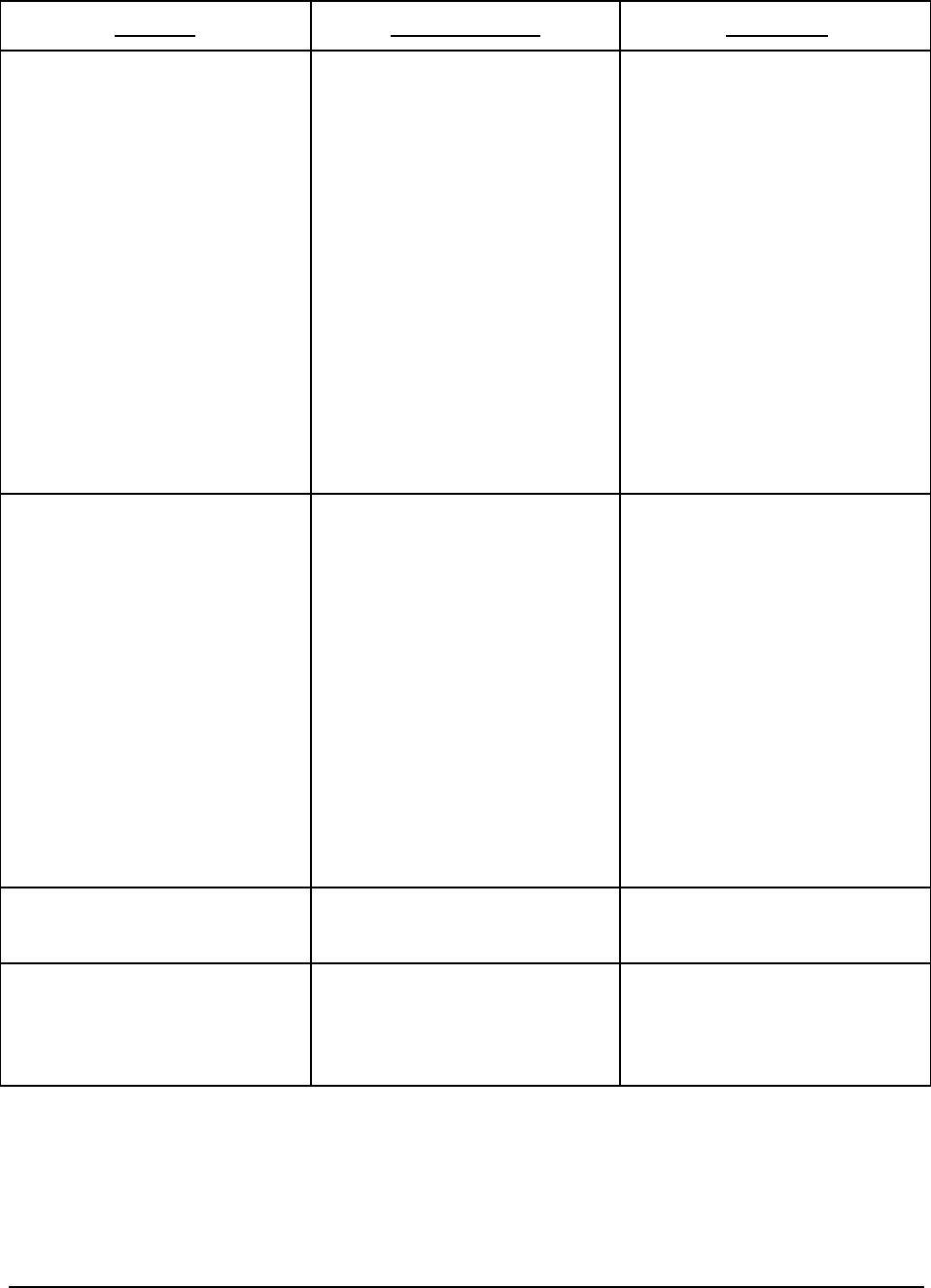

5.1 BASIC TROUBLESHOOTING CHART (Continued)

Problem Probable Cause Solution(s)

Not Spraying At All or

Inconsistent Material Flow

(spitting) With A Cup Gun

A. Air Cap too far from Fluid

Tip

B. Dry paint on end of Fluid Tip

C. Coating is too thick: not

enough pressure to pump

from cup to Fluid Tip

D. Foreign/unwanted particles

in the coating

E. Air Pressure Feed Tube

blocked: preventing

pressurization of paint cup

F. Cup Top Gasket not sealing

properly

G. Not enough paint in cup

A. Turn Sleeve Nut clockwise to

move Air Cap closer to Fluid

Tip

B. Clean Fluid Tip and continue

spraying

C. Add more thinning solvent if

possible

D. Empty cup; clean gun (see

Basic Clean Up, Sec. 4.1);

properly filter material when

pouring back into cup

E. See Sec. 4.3, Complete

Disassembly and Cleaning Of

Spray Gun

F. Tighten cup or see Sec. 4.5,

Replacing Cup Top Gasket

G. Check level and add

Not Spraying At All or

Inconsistent Material Flow

(spitting) With A Pressure-Fed

Gun

A. Air Cap too far from Fluid

Tip

B. Dry paint on end of Fluid Tip

C. Insufficient pressure in paint

tank

D. Fluid Line blocked

E. Fluid Line kinked

F. Paint Tank not properly

sealed

G. Not enough paint in tank

A. Turn Sleeve Nut clockwise to

move Air Cap closer to Fluid

Tip

B. Clean Fluid Tip and continue

spraying

C. Increase pressure in paint

tank

D. Disconnect Fluid Line from

gun and increase air pressure

in tank to flush hose.

E. Remove kink and straighten

as necessary

F. Tighten Wing Nuts on paint

tank or replace gasket if

necessary

G. Check level and add

Paint Leaking From Fluid Tip A. Damaged Needle and/or

Fluid Tip

B. Gland Nut too tight

A. Check and replace if

necessary

B. Loosen Gland Nut

Excessive Overspray A. Too much air volume for the

coating being sprayed

B. Spraying too far from the

surface

A. Use Variable Speed

Controller to reduce air

volume output of turbine

B. Spray 6-8” from the surface

to be coated