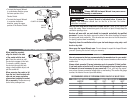

ROCKER SWITCH AND DIRECTION OF ROTATION

• To rotate the Impact Wrench

in a clockwise direction, press

the lower portion of the

Rocker Switch.

• To rotate the Impact Wrench

in a counter-clockwise

direction, press the upper

portion of the Rocker Switch.

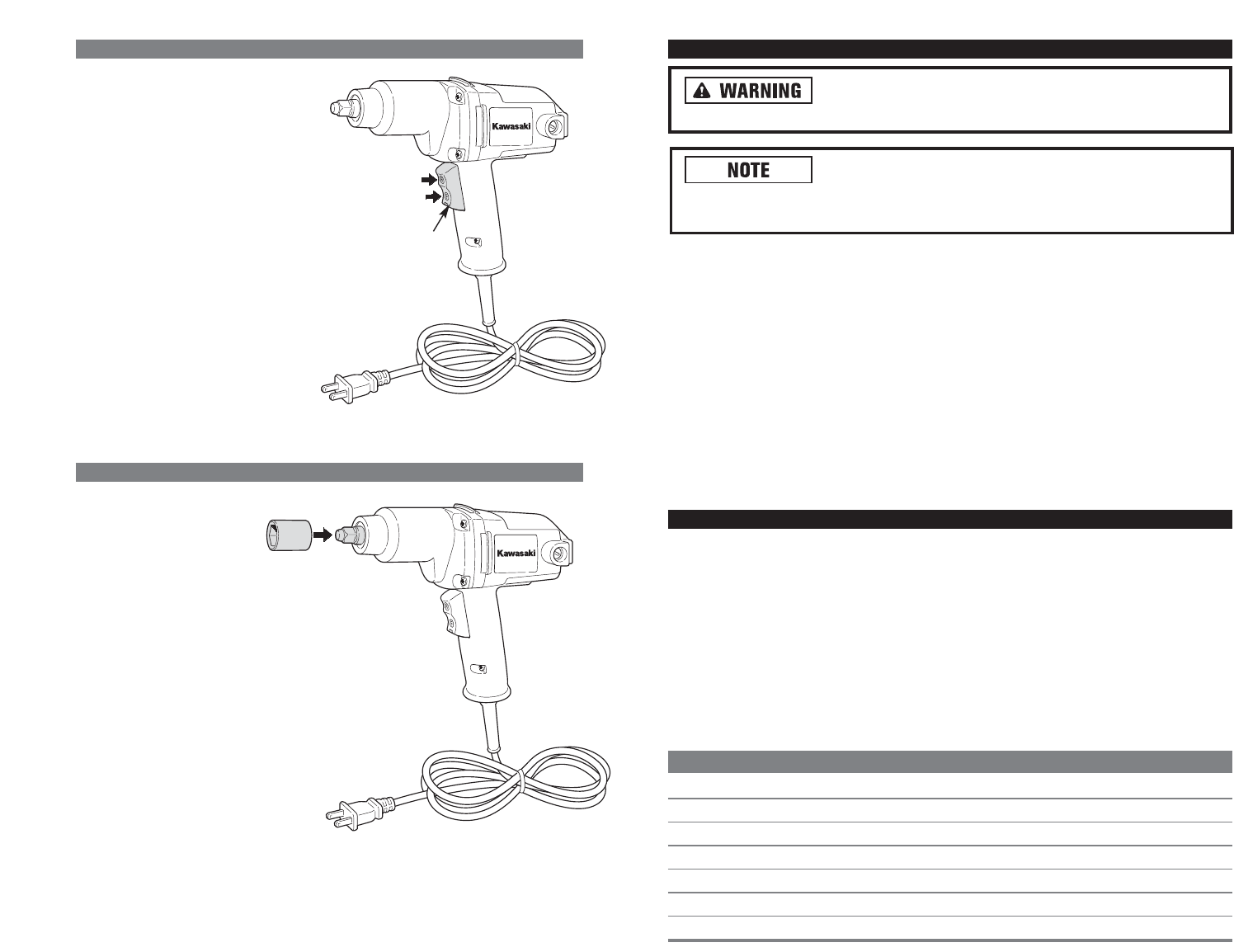

INSTALLING / REMOVING SOCKET

When installing a socket,

align the holes in the side

of the socket with the dent

pin. Press the socket on until

the dent pin engages in the hole.

To remove a socket, depress

the dent pin through the hole

using a small pointed object, and

pull the socket off.

When removing the socket or bit

from the tool, avoid contact with

skin and use proper protective

gloves when grasping the socket,

bit or accessory. Accessories may

be hot after prolonged use.

MAINTENANCE AND CLEANING

Always UNPLUG the Impact Wrench from power source

before attempting cleaning or maintenance.

This Impact Wrench is lubricated before it leaves the

factory. This lubrication should last for the life of the tool. No further

lubrication is required.

Use only mild soap and a damp cloth to clean the tool. Never let any liquid get

inside the casing. Never immerse any part of the tool in a liquid. Always keep the

ventilation openings clear.

Brushes will wear with use and should be inspected periodically by qualified

personnel. Unscrew the plastic caps on the sides of the motor housings to inspect

the spring and brush assembly. If the brushes are worn down to the line closest to

the spring, replace them immediately.

Regularly clean the ventilation slots in your tool and charger using only a soft

brush or dry cloth.

Never open the Impact Wrench case. Do not attempt to repair the Impact Wrench

yourself. Opening this tool will void your warranty.

ACCESSORIES

Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may become hazardous when used on

another tool.

Always attach grounded (3-prong) extension cords to grounded (3-hole) outlets.

If you must use an extension cord, be sure that the gauge is large enough to carry

the amount of current necessary for your power tool. If not, your tool may experi-

ence a loss of power, excessive voltage drop or overheating. The smaller the gauge

number, the heavier the cord (see table below).

RECOMMENDED SIZES OF EXTENSION CORDS 120 VOLT AC 60 HZ TOOLS

TOOL CURRENT RATING CONDUCTOR SIZE IN A.W.G

AMPERE 10FT. 25FT. 50FT. 100FT.

3-6 18 18 18 18

6-8 18 18 18 16

8-10 18 18 18 14

10-12 16 16 14 14

12-16 14 12 12 -

16-20 12 12 12 -

9

ROCKER

SWITCH

CLOCKWISE

COUNTER-CLOCKWISE