Description

Output Input

MIG Pulsed STT Flux-Cored

Power Feed

™

10R

Compact Wire Drive System for Automation

AUTOMATIC WIRE FEEDERS

The Power Feed 10R is a high performance, digitally controlled wire feeder designed to

be a part of a modular, multi-process welding system. It is specifically designed to mount to a

robot arm or to use in hard automation applications. Modular systems can be arranged in a

variety of ways for optimum, customized performance and easy maintenance. This four drive roll

feeder operates on 40VDC input power and is designed to be used with ArcLink™ Robotic

Power Wave™ power sources. Close integration of the feeder, power source and existing

equipment creates the foundation for a system with superior welding performance and reliability.

Publication E9.160 4/03

Web Update 1/07

www.lincolnelectric.com

Processes

Advantage Lincoln

Recommended Power Sources

Order

TECHNICAL SPECIFICATIONS

• Digitally controlled by the Power Wave power source, yielding

the best performance in the industry.

• Use with Lincoln power sources featuring ArcLink, the leading

digital communications protocol for welding, making it the best

choice for seamless integration with the power source and

networked equipment.

•Tachometer feedback provides calibration and precise control

of wire feed speed.

• Feeder brakes from maximum speed to zero in milliseconds,

minimizing the chance of wire sticking in the puddle.

• Select standard or high speed gears for wide wire feed speed

range.

• Split wire guides provide trouble-free feeding and offer fast,

tool-less wire installation, changeover and maintenance.

• Easy-to-read gauge for accurate drive roll tension.

•Brass-to-brass connections for good connectivity between

feeder and gun.

• Modular construction for easy servicing.

• Self loading wire feature for easy set-up.

Recommended General Options

Power Wave F355i, Power Wave 455M Robotic,

Power Wave 455M/STT Robotic, Power Wave 655R

Water Connection Kit, 14-Pin to 14-Pin Control Cable, 4 Drive Rolls

and Split Wire Guide, Torch Bushings, Incoming Conduit Bushings,

Wire Straightener, Magnum Low Drag Wire Conduit, Accu-Trak™

Drum Payoff Kit

K1780-2 Power Feed 10R

Call the Lincoln Electric Automation Division at 216.383.2667 for

more information.

Wire Size Range Wire Size Range Dimensions Net

Product Product Wire Feed Speed Range Solid Cored H x W x D Weight

Name Number inches/min (m/min) inches (mm) inches (mm) inches (mm) lbs (kg)

Power Feed 10R K1780-2 50-800 in/min (1.3-20.3m/min) .025-3/32 in (0.6-2.4mm) .035-.120 in. (0.9-3.0mm) 8.9 x 10.3 x 8.1 22.4 lbs

75-1200 in/min (2.0-30.5 m/min) .025-1/16 in (0.6-1.6mm) .035-5/64 in (0.9-2.0mm) (226 x 261 x 206) (10.2 kg)

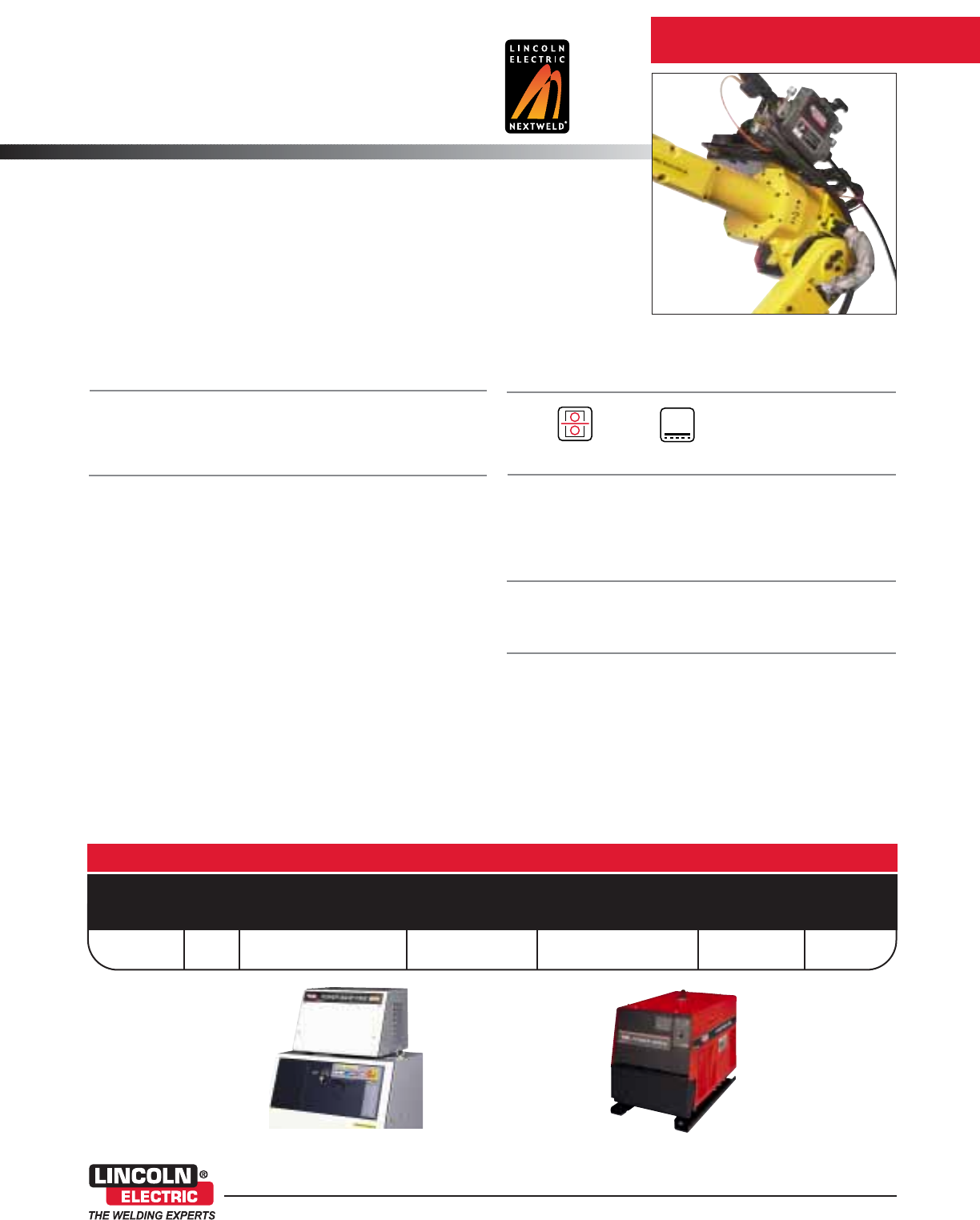

Power Feed 10R mounted

on FANUC Robot Arm.

Power Wave F355i shown integrated with

FANUC Arc-Mate RJ3iB controller.

Power Wave 455M Robotic.

40

VDC