US-M1800-LS

Date:

11/5/06

MSDS No.:

Blue Max Nyloid 2

Trade Name:

Sizes: All

2/1/04

Supersedes:

M A T E R I A L S A F E T Y D A T A S H E E T

For Welding Consumables and Related Products

Conforms to Hazard Communication Standard 29CFR 1910.1200 Rev. October 1988

SECTION I - IDENTIFICATION

Product Type:

Covered Electrode

Manufacturer/

The Lincoln Electric Company

Supplier:

22801 St. Clair Avenue

Cleveland, OH 44117-1199

Classification:

AWS ENiCrMo-6

(216) 481-8100

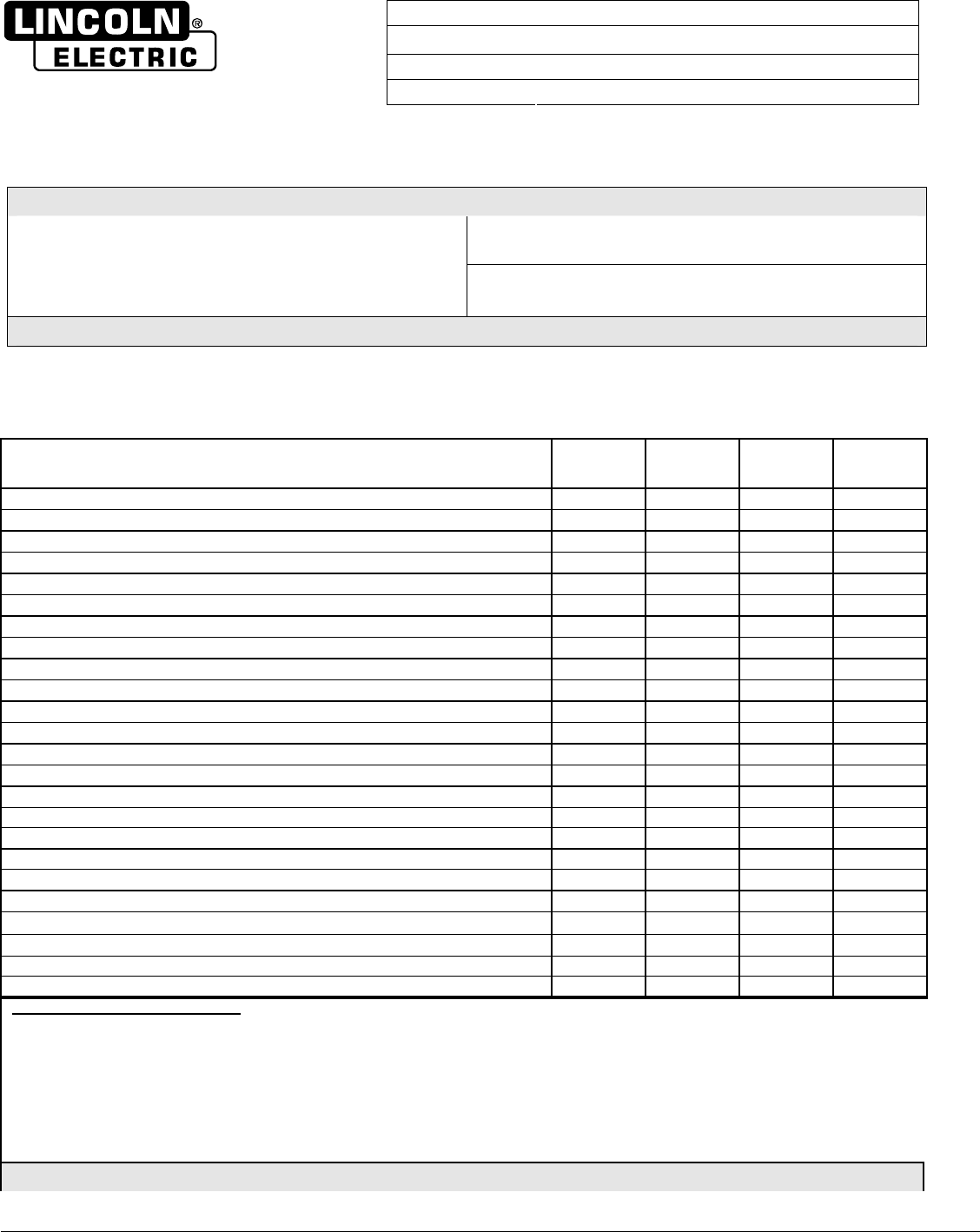

SECTION II - HAZARDOUS MATERIAL (1)

I M P O R T A N T !

This section covers the materials from which this product is manufactured. The fumes and gases produced during welding with the normal

use of this product are covered by Section V; see it for industrial hygiene information.

CAS Number shown is representative for the ingredients listed. All ingredients listed may not be present in all sizes.

(1) The term “hazardous” in “Hazardous Materials” should be interpreted as a term required and defined in the Hazards Communication

Standard and does not necessarily imply the existence of any hazard. All materials are listed on the TSCA inventory.

TLV PEL

Ingredients: CAS No. Wt.%

mg/m

3

mg/m

3

Chromium and chromium alloys or compounds (as Cr)***** 7440-47-3 10 0.5(b) 1.0(b)

Limestone and/or calcium carbonate 1317-65-3 10 10 15

Molybdenum alloys (as Mo) 7439-98-7 5 10 10

Iron 7439-89-6 < 5 10* 10*

Silicates and other binders 1344-09-8 < 5 10* 10*

Fluorides (as F) 7789-75-5 < 5 2.5 2.5

Manganese and/or manganese alloys and compounds (as Mn)***** 7439-96-5 < 5 0.2 1.0(c)

Niobium alloys (as Nb) 7440-03-1 < 5 10* 10*

Tungsten alloys and compounds (as W) 7440-33-7 1 5 5

Mineral silicates 1332-58-7 0.5 5** 5**

Silicon and/or silicon alloys and compounds (as Si) 7440-21-3 0.5 10* 10*

Titanium dioxides (as Ti)***** 13463-67-7 < 0.5 10 15

Titanium and/or titanium alloys (as Ti) 12719-90-3 < 0.5 10* 10*

Aluminum and/or aluminum alloys (as Al)***** 7429-90-5 < 0.5 10 15

Nickel core wire*****

7440-02-0 55 1.5 1

Supplemental Information: (*) Not listed. Nuisance value maximum

is 10 milligrams per cubic meter. PEL value for iron oxide is 10 milligrams per

cubic meter. TLV value for iron oxide is 5 milligrams per cubic meter.

(b) The OSHA PEL for chromium (VI) is 5 micrograms

(0.005 milligrams) per cubic meter. The TLV for water

soluble chromium (VI) is 0.05 milligrams per cubic meter

and the TLV for insoluble chromium (VI) is 0.01

(**) As respirable dust.

milligrams per cubic meter.

(*****) Subject to the reporting requirements of Sections 311, 312, and 313 of

the Emergency Planning and Community Right-to-Know Act of 1986

and of 40CFR 370 and 372.

(c) Values are for manganese fume. STEL (Short Term

Exposure Limit) is 3.0 milligrams per cubic meter.

Values are those proposed by OSHA in 1989. Present

PEL is 5.0 milligrams per cubic meter (ceiling value).

SECTION III - HAZARD DATA

Non Flammable; Welding arc and sparks can ignite combustibles and flammable products. See Z49.1 referenced in Section VI.

Product is inert, no special handling or spill procedures required. Not regulated by DOT.

Rev 11/06b (CONTINUED ON SIDE TWO)