Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

PRO-CUT 60

F-42

TRANSISTOR MODULE REMOVAL

REMOVAL/REPLACEMENT

PROCEDURE

NOTE: It is recommended that when

the Transistor Module is replaced,

the Power Board and the Control

Board should be replaced.

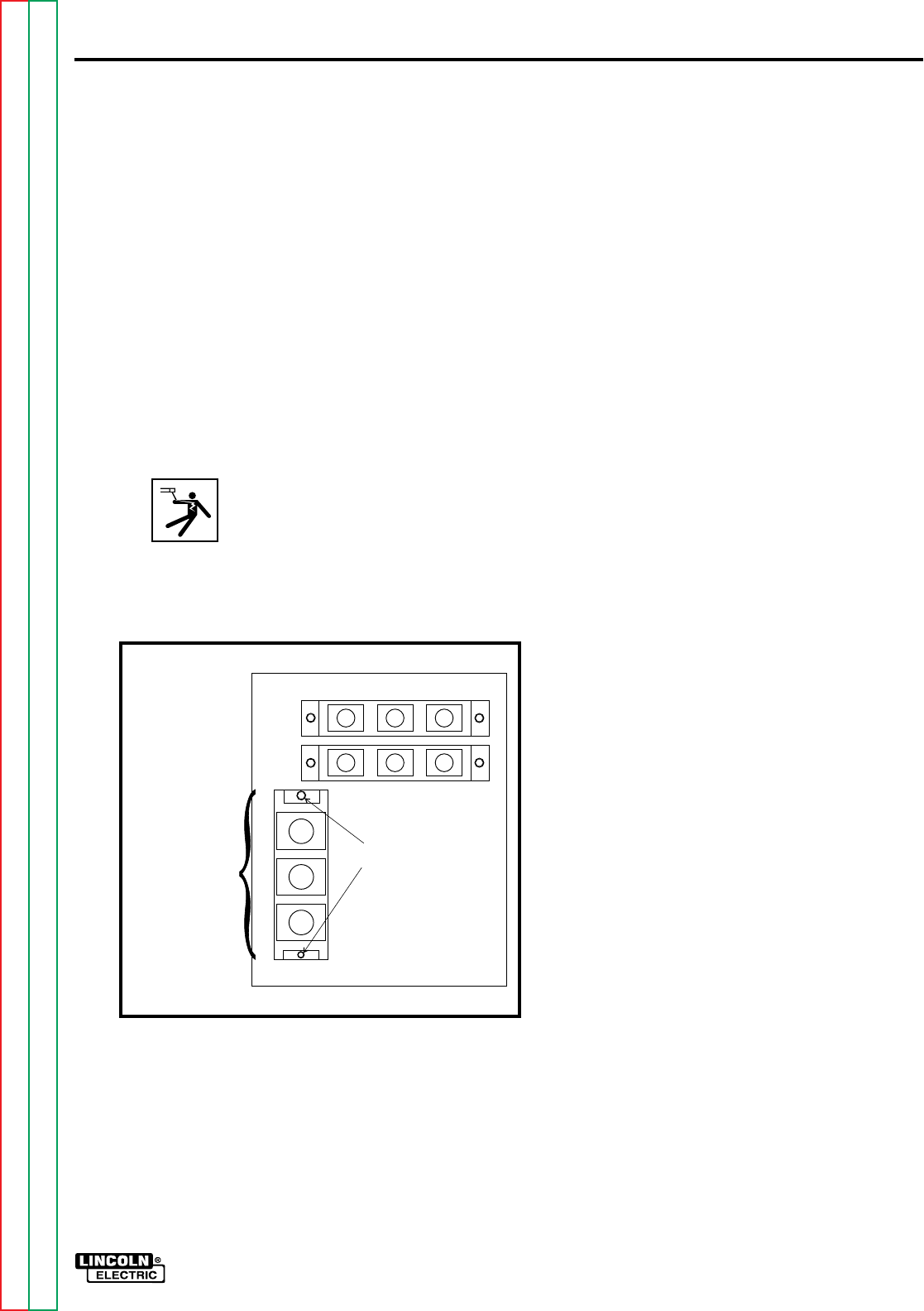

NOTE: See Figure F.15.

1. Disconnect input power to the

machine.

2. Remove the Left Case Side

assembly.

3. Perform the CAPACITOR

DISCHARGE PROCEDURE.

4. Perform the POWER BOARD

REMOVAL PROCEDURE.

5. Remove the two socket head

cap screws from the Transistor

Module using the 5mm Allen-

Type wrench.

6. Remove the Transistor Module

from the heat sink.

7. Install the replacement

Transistor Module.

a. Clean the heat sink surface

with “000 fine steel wool.

b. Rinse the heat sink surface

with alcohol or acetone.

c. Apply a .002” to .005” coat

of joint compound evenly to

the heat sink mounting

surface and the Transistor

Module mounting surface.

Use Lincoln Joint

Compound T12837, or

equivalent, such as Dow

Corning #340.

d. Press the Transistor Module

onto the heat sink surface.

Remove the module to make

sure enough joint compound

has been applied. When

removed, both surfaces

should have an even texture

with no bare spots. If this

even-textured look does not

appear, re-apply the joint

compound.

e. Mount the Transistor Module

on the heat sink with the

5mm socket head cap

screws to 26 in/lbs. Partially

tighten each cap screw one

at a time to avoid uneven

torque on the base plate.

8. Install replacement Power

Board. See POWER BOARD

REMOVAL PROCEDURE.

TRANSISTOR

MODULE

SOCKET HEAD

CAP SCREWS

(TORQUE TO

26 IN/LBS (2.9 N/M))

FIGURE F.15-Transistor Module loca-

tion with Power Board Removed