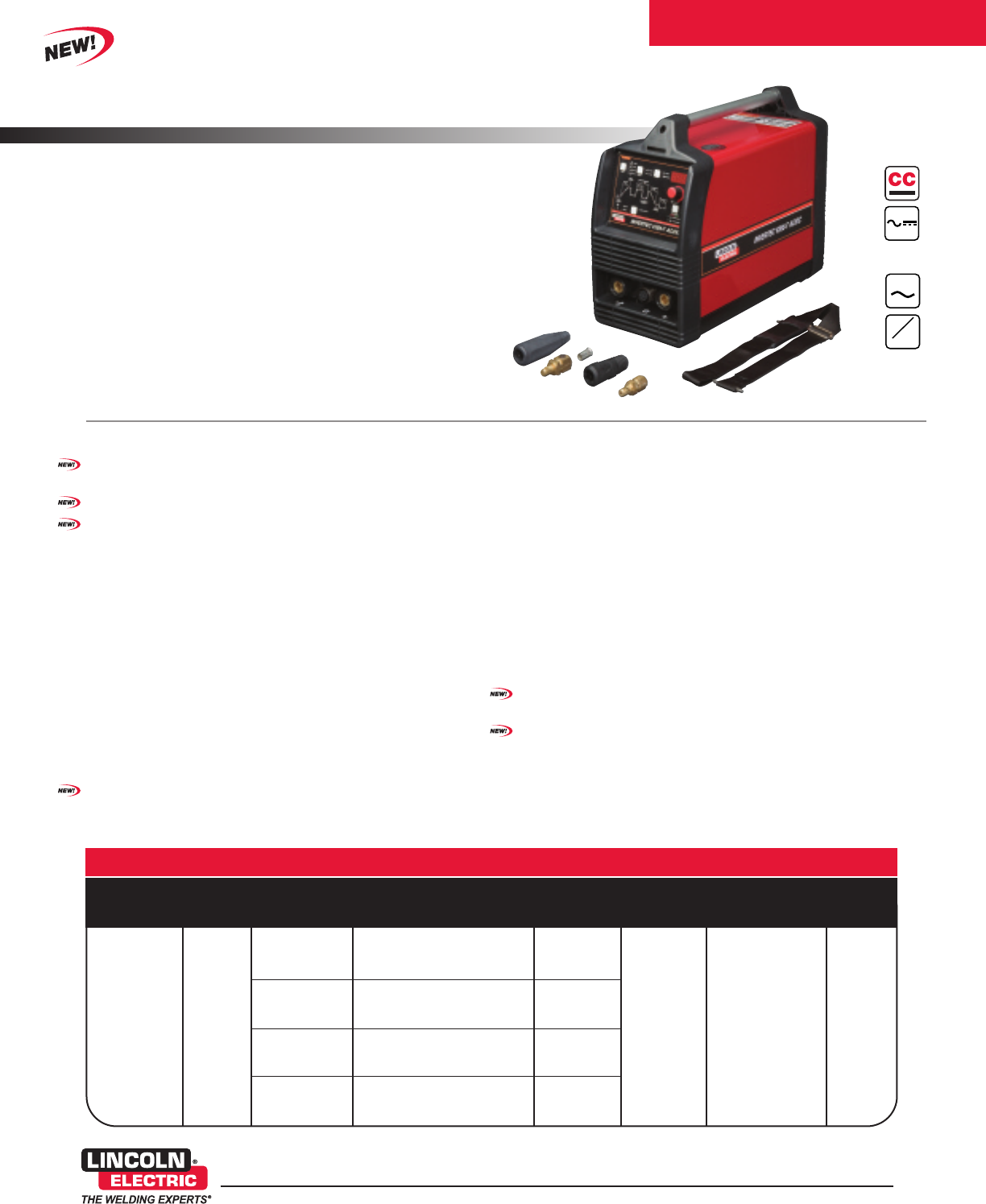

Invertec

®

V205-T AC/DC

For TIG and Stick Welding

TIG WELDERS

Publication E3.110 06/07

Web Update 06/08

www.lincolnelectric.com

The Invertec

®

V205-T AC/DC is a compact, TIG power source intended

for critical AC or DC TIG welding. From maintenance to production fabri-

cation, to motorsports, aerospace, nuclear piping and shipbuilding, this

feature-packed inverter is flexible enough for almost any job! Variable

AC frequency allows you to focus the arc when precise control is

required. The 115/230V input voltage auto-reconnect makes the V205-T

AC/DC extremely useful almost anywhere in the shop or in the field.

AC

D

C

1

PHASE

60

5

0

H

z

TECHNICAL SPECIFICATIONS

Input Dimensions

Product Product Rated Output Current @ Output H x W x D Net Weight

Name Number Input Power Current/Voltage/Duty Cycle Rated Output

(1)

Range inches (mm) lbs.(kg)

Invertec

®

150A/16.0V/40% TIG 34.0A

V205-T AC/DC K1855-4 115V/1/50/60 120A/14.8V/60% TIG 25.0A

100A/14.0V/100% TIG 20.0A

200A/18.0V/40% TIG 30.0A

230V/1/50/60

(2)

170A/16.0V/60% TIG 18.0A 6-200 A

140A/15.6V/100% TIG 15.0A AC/DC 15.0 x 8.5 x 19.0 38

110A/24.4V/35% Stick 34.0A Max. OCV: (381 x 216 x 483) (17.3)

115V/1/50/60 90A/23.6V/60% Stick 28.0A 53.7

70A/22.8V/100% Stick 20.0A

180A/27.2V/35% Stick 30.0A

230V/1/50/60

(2)

150A/26.0V/60% Stick 23.0A

130A/25.2V/100% Stick 19.0A

(1) Input amps on 60Hz input. (2) Also operates on 208 input volts.

Output

Input

Precision Arc Performance

• Added Stick Crisp Mode for exceptional Fleetweld

®

5P and 5P+ (E6010)

Performance.

• Improved TIG starting. Now starts DC(-) to maintain a sharp tungsten.

• Adjustable DC strike mode – Allows adjustment of a hotter or colder start

depending on the tungsten diameter.

• AC/DC inverter for TIG with advanced inverter technology to optimize arc

performance.

• Adjustable AC output frequency allows the operator to focus the arc

minimizing the heat affected zone.

• Extended AC Balance Control helps maintain a pointed tungsten to direct

the arc in the weld joint.

• Selectable waveshapes – Square wave for fast travel speeds and

excellent puddle control, sine wave for a traditional softer sounding arc,

triangular wave to reduce the heat input into the weld at low amperages.

• High quality stick welding with such popular Lincoln

®

electrodes as

Fleetweld

®

5P, 35, 37, 180 and Excalibur

®

7018.

Professional Features

• Voltage Reduction Device (VRD). When enabled from the set up menu

reduces the open circuit voltage in STICK mode for use in electrically

hazardous conditions or when the use of a VRD is required.

• 200 amps @ 40% duty cycle is the highest output rating in this

machine class.

• Auto-reconnects for single phase 115/230V 50/60 Hz input allows

the flexibility to weld in the shop or take in the field where 230V

may not be available.

• Weighs in at a mere 38 lbs. (17.3 kg) making it easy to carry around the

shop or job site.

Simple Controls

• Full featured TIG control – up to 11 variable – including pulse, upslope,

downslope and balance control.

• Easy to read sequence diagram with LEDs displays selected parameter

for easy setting with a single knob.

Outstanding Quality

• Fan-As-Needed (F.A.N.) fan only operates when needed to reduce power

consumption, noise and dust in machine.

• Newly designed using the latest power electronic technology for

improved reliability.

• CSA C/US Certified.

• Three-Year Lincoln

®

Warranty on parts and labor.

Advantage Lincoln

Stick, TIG

Processes