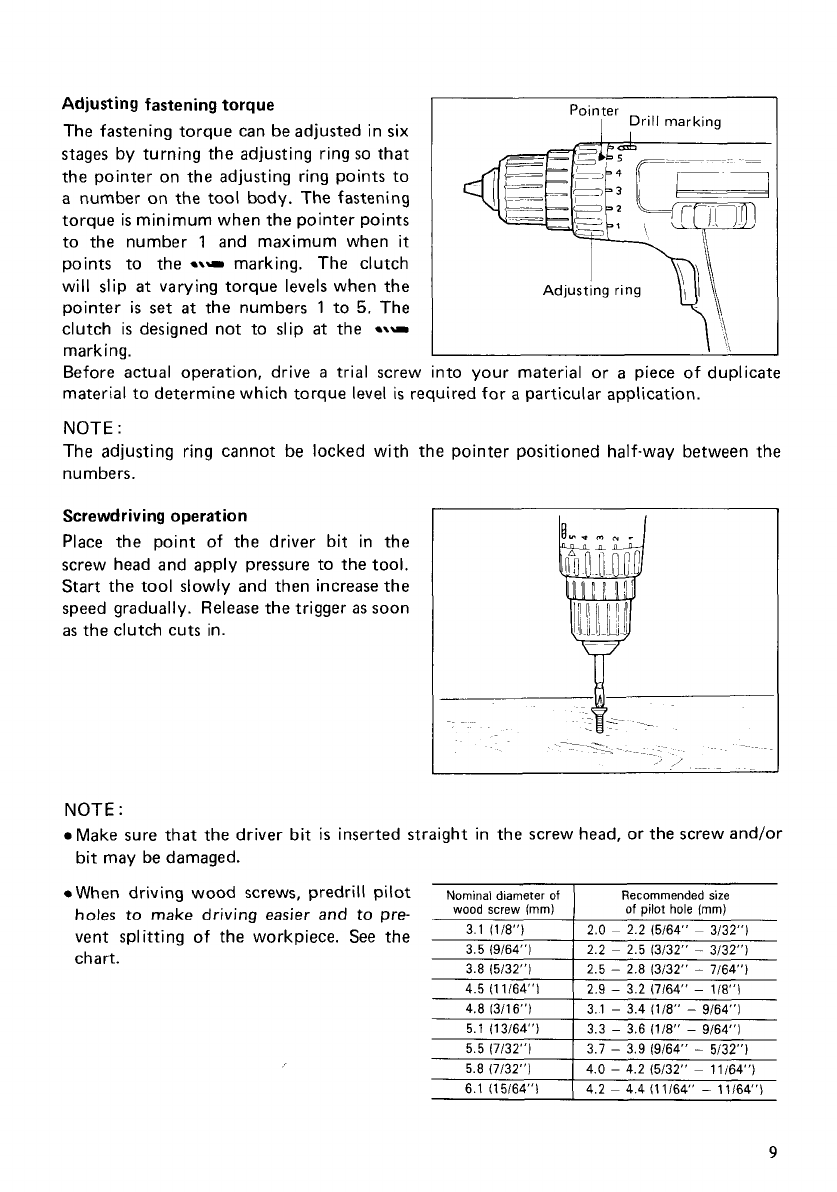

Adjusting fastening torque

The fastenina toraue can be adiusted in six

-

stages

by turning the adjusting ring

so

that

the pointer on the adjusting ring points to

a

number on the tool body. The fastening

torque

is

minimum when the pointer points

to the number

1

and maximum when

it

points to the

-8-

marking. The clutch

will slip

at

varying torque levels when the

pointer

is

set

at

the numbers

1

to

5.

The

clutch

is

designed not to slip

at

the

-8-

marking.

Pointer

1

Drill

marking

Before actual operation, drive

a

trial screw into your material or

a

piece of duplicate

material to determine which torque

level

is

required

for

a

particular application.

NOTE

:

The adjusting ring cannot be locked with the pointer positioned half-way between the

numbers.

Nominal diameter

of

wood screw

Imm)

Screwdriving operation

Place the point

of

the driver bit in the

screw head and apply pressure to the tool.

Start the tool slowly and then increase the

speed gradually. Release the trigger

as

soon

as

the clutch cuts in.

Recommended size

of

Dilot

hole

lmm)

NOTE

:

Make sure that the driver bit

is

inserted straight in the screw head, or the screw and/or

bit may be damaged.

3.8

15/32")

4.5 (11/64"1

4.8 13/16")

s

When driving wood screws, predrill pilot

holes

to

make

driving

easier

and to pre-

vent splitting of the workpiece.

See

the

chart.

2.5

-

2.8 (3132"

-

7/64")

2.9

-

3.2 (7164''

-

118")

3.1

-

3.4 1118"

-

9164"l

5 5

17/32")

5 8 (7132")

6

1 (15164")

3

1

(118")

1

2.0

-

2.2 15/64"

-

3132")

3.5

(9164")

I

2.2

-

2.5 13132"

-

3/32")

3 7

-

3 9 (9164"

-

5132")

4

0

-

4

2

15132"

-

11 164")

4

2

-

44 111164'

-

11/64'1

5.1 113164")

I

3.3

-

3.6

1118"

-

9/64"1

9