22

ENGLISH

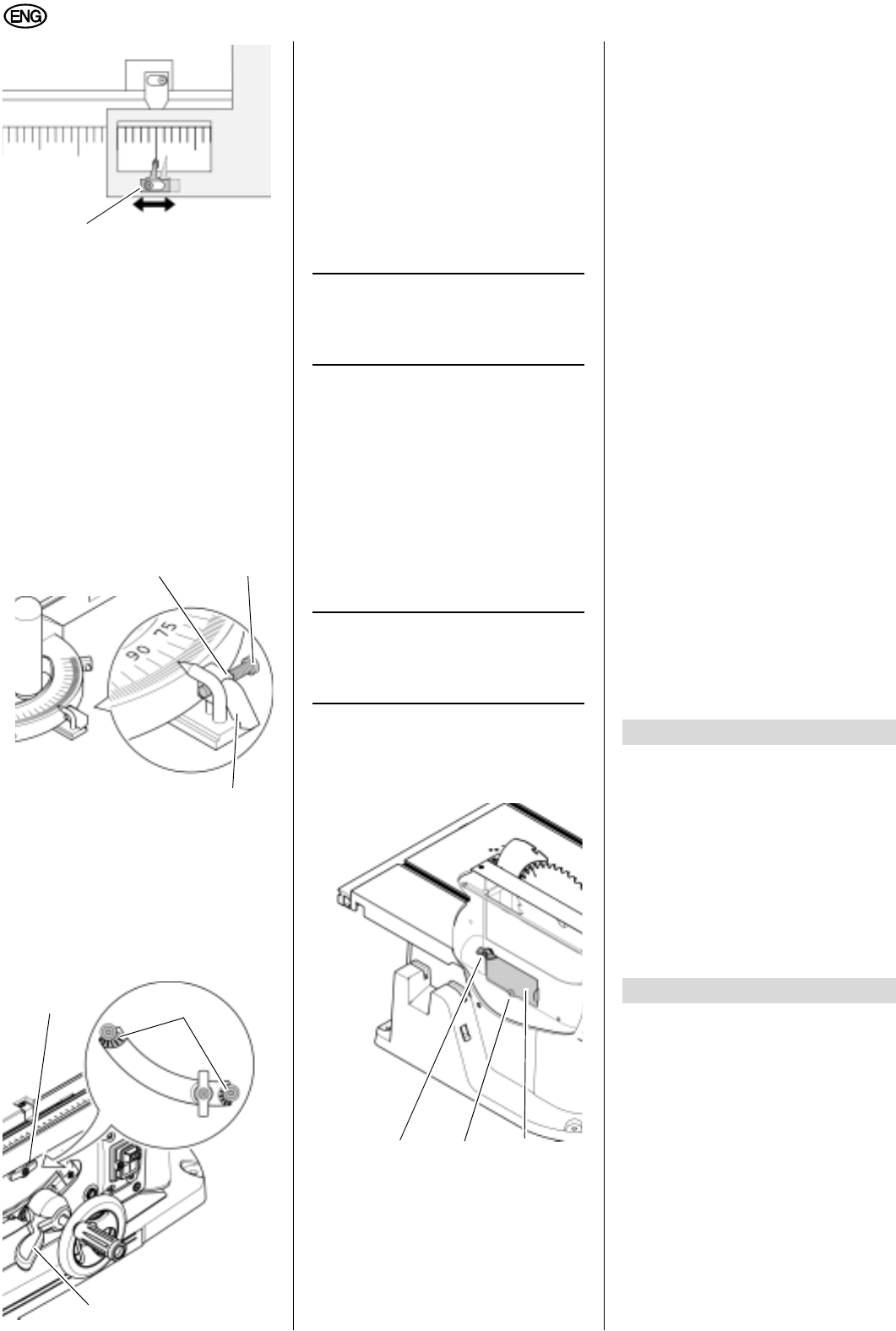

9.4 Adjusting the mitre fence

stops

The mitre fence's positive stops at both

45° positions and the 90° position are

adjustable.

1. Loosen the mitre fence locking han-

dle.

2. Set mitre fence to any positive stop

position and lock with locking handle.

3. Loosen locking nut (67) and turn

screw (68) so far out, until flip stop

(69) can be turned forward.

4. Turn screw (68) in until it just

touches the flip stop (69).

5. Tighten locking nut. The flip stop

should move without difficulty.

9.5 Adjusting the blade tilt stop

1. Set release lever (70) horizontal and

let engage (0q bis 45q).

2. Release lock lever (72) and set saw

blade tilt to 0°/45°.

3. Lock set bevel tilt by tightening lock

lever (72).

4. Check blade bevel angle:

0qsquare with the saw table

45qwith separate mitre square.

If these angles are not exactly

matched:

5. Adjust cam plates (71) of stops until

blade tilt against the saw table at

end positions is exactly 0°= square)

and 45°respectively.

3

Note:

To adjust the bevel tilt stop for

-1.5° to 46.5°, the release lever must be

pulled out and set into vertical position.

9.6 Saw Cleaning

x Remove chips and saw dust with

vacuum cleaner or brush:

from saw blade setting guide ele-

ments;

from motor vent slots;

chipcase.

Cleaning the chipcase.

If there is sawdust build-up in the chip-

case, the chipcase needs cleaning:

3

Note:

The chipcase is accessible from

below only. For cleaning, both table

insert and saw blade may be removed.

1. Loosen screw (74) only slightly.

2. Remove thumb screw (75).

3. Turn lid (73) 180°.

4. Clean chipcase.

5. Close lid (73) again, turn in thumb

screw (75). Then tighten both

screws (74), (75) hand-tight only.

9.7 Saw storage

A

Danger!

Store saw so that

it cannot be started by unauthor-

ized persons, and

nobody can get injured.

A

Caution!

Do not store saw unprotected

outdoors or in damp environment.

9.8 Maintenance

Before switching ON

Visual check to see if

distance saw blade – riving knife is

5 mm maximum;

riving knife is in line with saw blade.

Visual check of power cable and power

cable plug for damage; if necessary

have damaged parts replaced by a qual-

ified electrician.

Monthly (if used daily)

Remove saw dust and chips with vac-

uum or brush; apply light coat of oil to

guide elements:

threaded rod and guide rods of

blade rise and fall mechanismn:

swivel segments.

Every 300 hours of operation

Check all screwed joints, retighten if

necessary.

x Before cutting a workpiece to size

make trial cuts on pieces of scrap.

x Always place a workpiece on the

saw table in such way that it cannot

tilt or rock (e.g. always place a

curved board on the table with the

convex side up).

x To simplify repetitive cut-off work

use a stock stop .

x Keep surface of table clean.

For special tasks the following accesso-

ries are available at your specialized

dealer – see back cover for illustrations:

A Floor Stand

Provides for a secure machine

stand and optimal working height;

ideal in mobile use, folds up for sav-

ing space.

B Dust Collection Attachment

Helps to protect your health and to

keep the shop clean.

C Roller/Ball Transfer Stand

For accurate guiding of long stock.

D TCT Saw Blade

250 x 2.6/1.6 x 30, 48 inverted V/

hollow teeth, 2 pinholes

66

67 68

69

70

72

71

75 74 73

10. Tips and Tricks

11. Available Accessories