OM-1588 Page 34

13-2. Redefining Teach Points

Ref. S-0259 / Ref. ST-154 109

1 IPM

IPM determines the weld metal de-

position rate.

. Redefining IPM is not normally

required unless special wire or

unusual joint design is needed.

Use front panel parameter select

button to move > to select IPM. Use

Display Control to select teach

point value.

Press and hold Purge button while

turning Display Control to redefine

the ipm teach point. For example:

there are teach points at 150, 200,

and 250 ipm; the teach point at 200

can be adjusted to a wire feed

speed of 151 to 249 ipm.

2 Vpk − Peak Voltage

Arc voltage during peak current

phase of the pulse waveform. This

determines arc length during

adaptive pulse welding.

3 Apk − Peak Amperage

4 Abk − Background Amperage

Peak and background amperage

depend on the range of the welding

power source.

5 PPS − Pulses Per Second Of

20-400

6 PWms − Pulse Width Of

1.0-5.0 Milliseconds

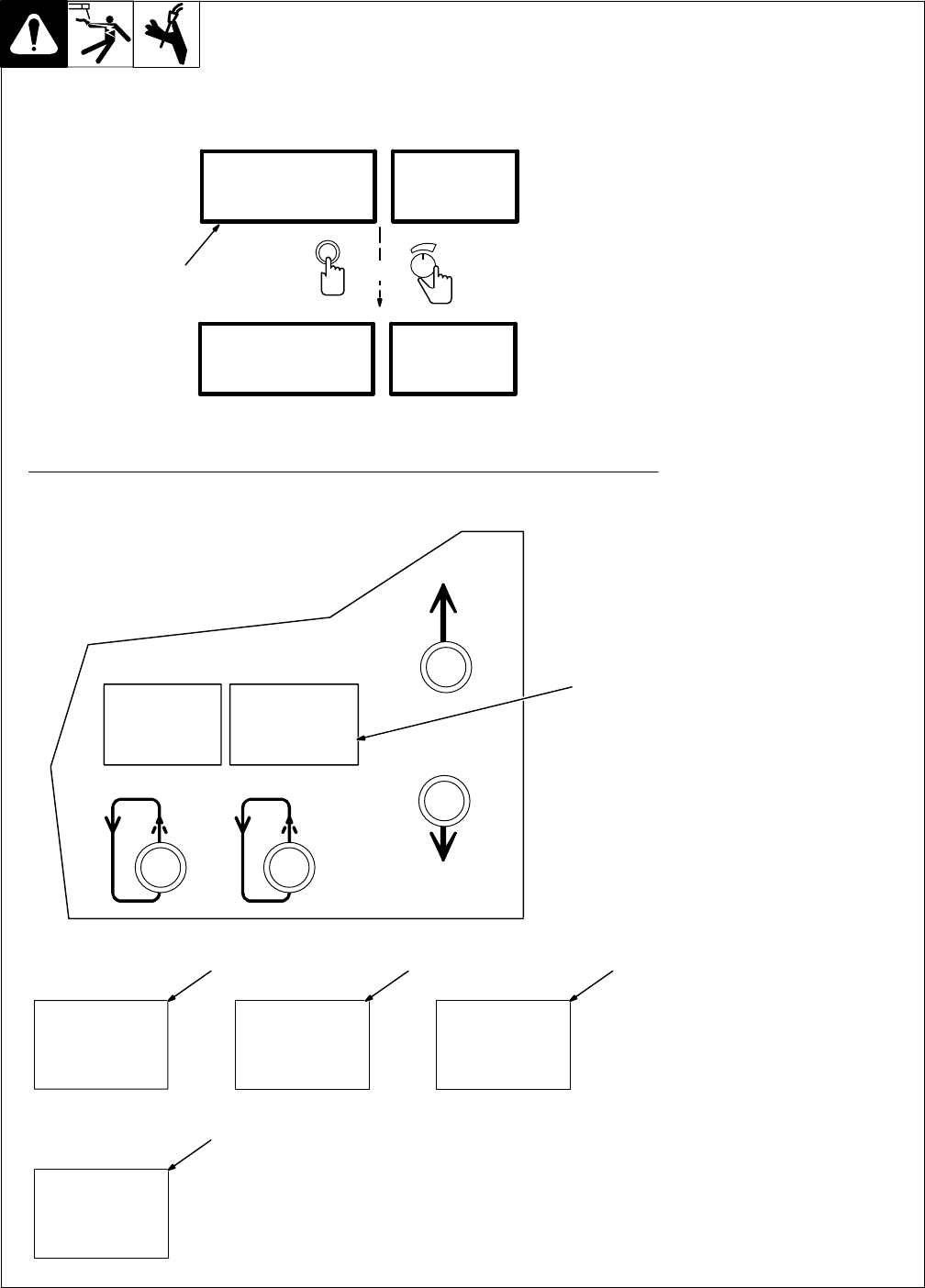

Use side panel controls to change

pulse parameters. See Menu Guide

for detailed programming steps.

After values are set, strike and

maintain an arc for five seconds.

Do this for each teach point.

End weld by releasing gun trigger,

not by pulling gun out of weld. Re-

peat for each custom teach point.

The taught arc length represents a

Trim (arc length) setting of 50.

Once the teach points are set, the

wire feeder adjusts parameters be-

tween teach points synergically.

Redefining IPM Teach Point

Redefining Pulse Parameters

50 Tr im

>450 IPM

Prg 1

Pu l se

50 Tr im

>460 IPM

Prg 1

Pu l se

1

Purge

And

Process

400 IPM

32.4 Vpk

>385 Apk

108 Abk

2

32.4 Vpk

385 Apk

>1 0 8 A b k

126 PPS

385 Apk

108 Abk

>126 PPS

2.3 PWms

34 5

Teach On

400 IPM

>3 2 . 4 V p k

385 Apk

385 Apk

108 Abk

126 PPS

>2 . 3 PWm s

6