. A complete Parts List is available at www.MillerWelds.com

OM-1327 Page 19

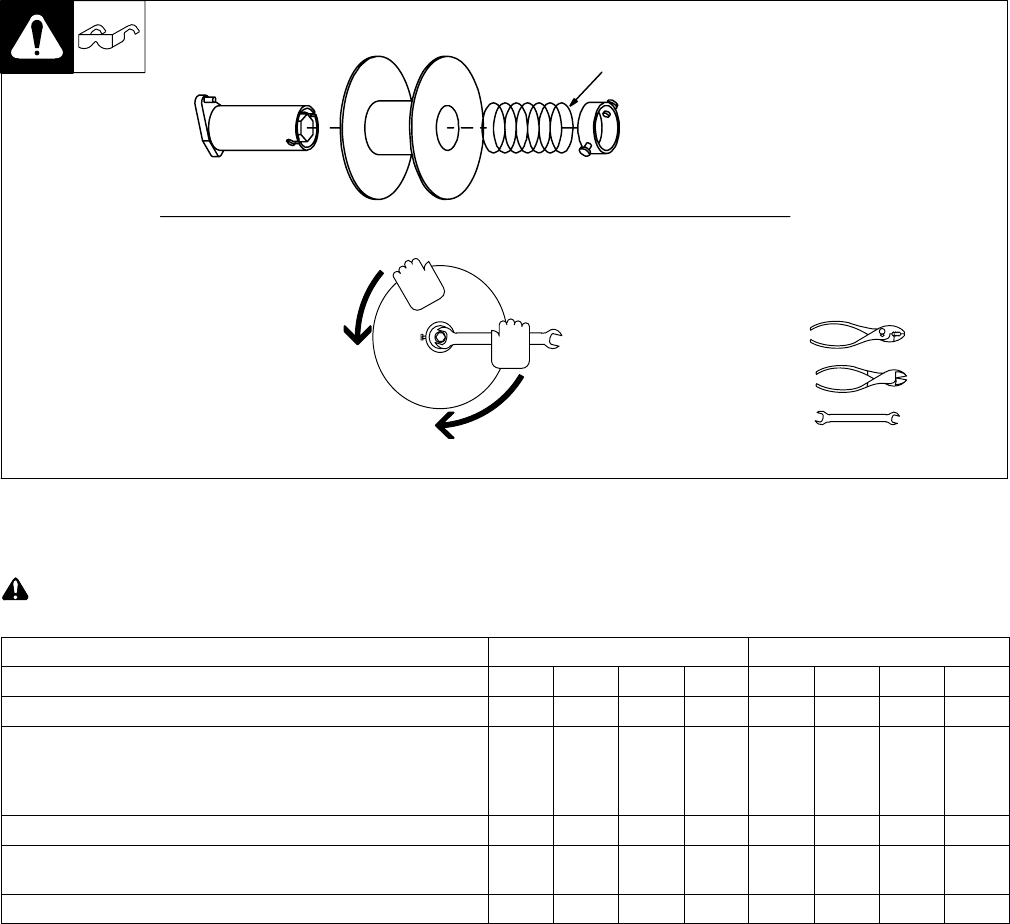

3-12. Installing Wire Spool and Adjusting Hub Tension

072573-B

When a slight force is needed to turn spool, tension is set.

15/16 in

Use compression spring with

8 in (200 mm) spools.

Tools Needed:

3-13. Electrical Service Guide

Failure to follow these electrical service guide recommendations could create an electric shock or fire hazard. These recommenda-

tions are for a dedicated branch circuit sized for the rated output and duty cycle of the welding power source.

60 Hz Single Phase 60 Hz Three Phase

Input Voltage 200 230 460 575 200 230 460 575

Input Amperes At Rated Output 69 61 30 24 34 30 15 12

Max Recommended Standard Fuse Rating In Amperes

Circuit Breaker

1

, Time-Delay

2

80 70 35 25 40 35 15 10

Normal Operating

3

100 90 40 35 50 45 20 15

Min Input Conductor Size In AWG

4

6 8 10 12 10 10 14 14

Max Recommended Input Conductor Length In Feet (Meters)

101

(31)

86

(26)

229

(70)

217

(66)

86

(26)

114

(35)

178

(54)

277

(85)

Min Grounding Conductor Size In AWG

4

8 8 10 12 10 10 14 14

Reference: 2005 National Electrical Code (NEC) (including article 630)

1 Choose a circuit breaker with time-current curves comparable to a Time Delay Fuse.

2 “Time-Delay” fuses are UL class “RK5” .

3 “Normal Operating” (general purpose - no intentional delay) fuses are UL class “K5” (up to and including 60 amp), and UL class “H” ( 65 amp and

above).

4 Conductor data in this section specifies conductor size (excluding flexible cord or cable) between the panelboard and the equipment per NEC Table

310.16. If a flexible cord or cable is used, minimum conductor size may increase. See NEC Table 400.5(A) for flexible cord and cable requirements.

NOTICE − This unit is either a 200/230/460 ac input voltage model or 460/575 ac input voltage model. See rating label on unit and check voltage

available at site to be sure it matches the voltage specified on the rating label.