OM-216 244 Page 15

SECTION 5 − INSTALLATION - STUD GUN

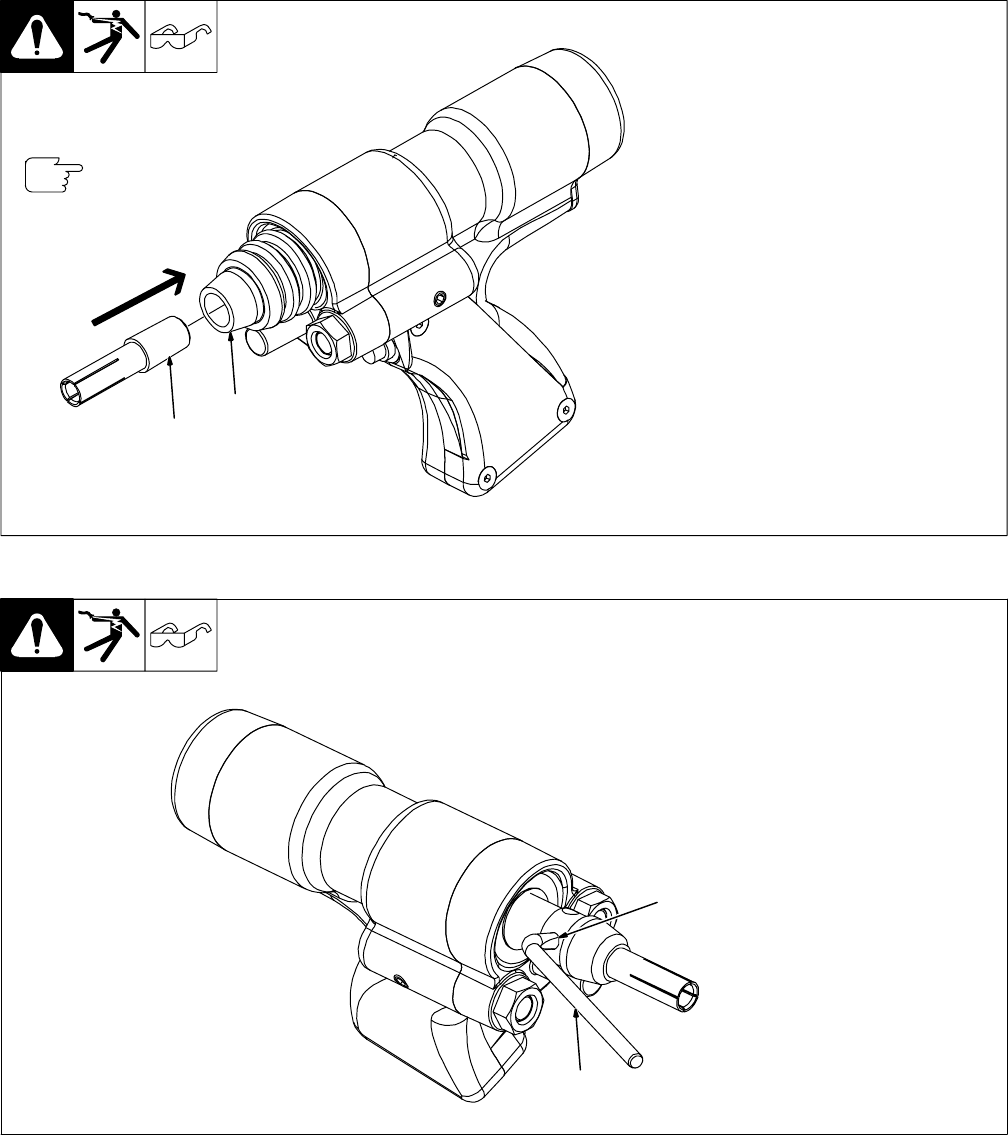

Y Disconnect gun from power

source before installing or

removing components.

1 Chuck

2 Chuck Adapter

To install chuck, align chuck in front

of chuck adapter. Tap firmly on the

end of chuck to seat chuck into

adapter. Not necessary to pound

on the end of the chuck. This will da-

mage the chuck.

. There is a unique chuck for ev-

ery diameter of stud. Rectan-

gular and other special shape

studs may require specialized

chucks. There is also a depth

stop inside of the chuck. The

depth stop should be adjusted

so that you are retaining a good

portion of the stud you are set-

ting up to weld. Typically, this is

one third to one half of the

length of the stud being welded.

1

5-1. Chuck Installation

2

Do not hammer or beat

chuck into position.

1 Chuck Key

2 Hole - Chuck Adapter

To remove chuck, insert short, ta-

pered end of chuck ejector key into

one of the holes in the side of the

chuck adapter. It may be necessary

to move the rubber bellows to see

the holes in the side of the chuck

adapter.

Rotate chuck key clockwise or

counter clockwise and the chuck

will pop out of the chuck adapter.

. Chuck is held into the chuck

adaptor with a #2 morse taper.

1

5-2. Chuck Removal

2