OM-216 244 Page 25

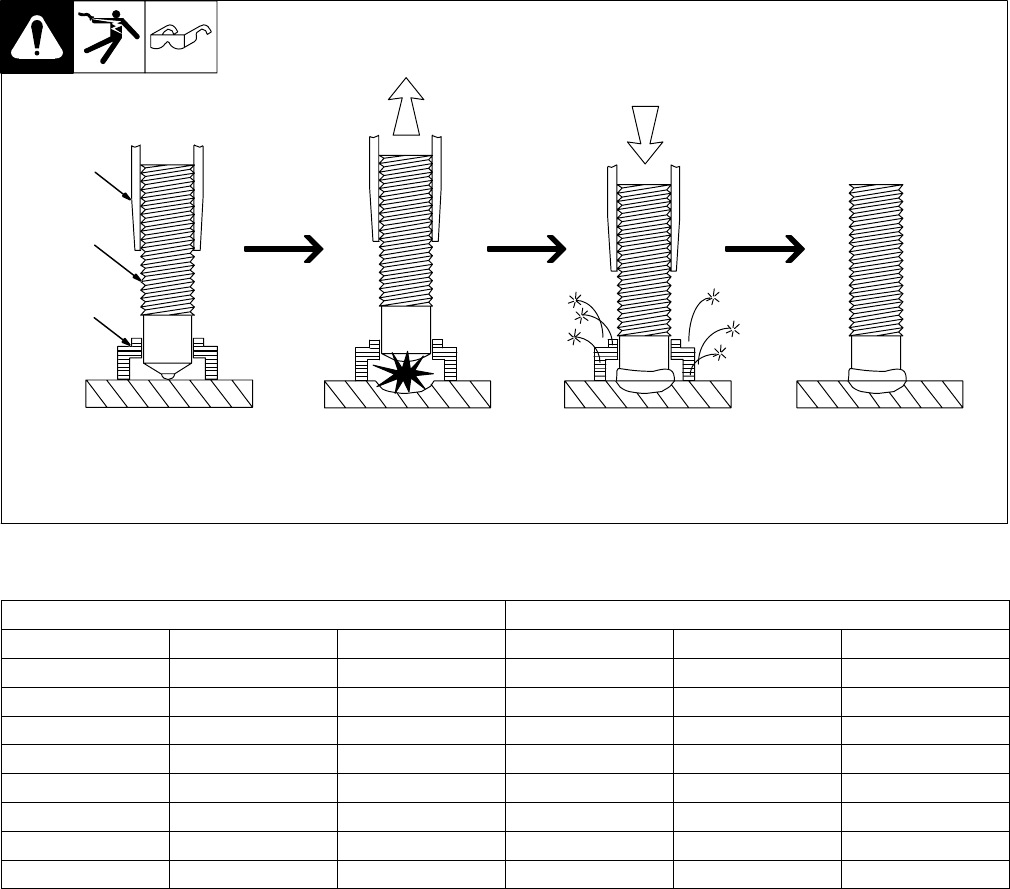

7-3. Welding Sequence

Gun is properely

positioned and main

gun spring is partially

compressed.

Trigger is pressed and the

stud lifts off the work. An

arc is created and melts the

stud and parent material.

After arcing is complete,

the main spring plunges

the stud into the molten

pool of metal.

Gun is withdrawn

from the welded stud.

The ferrule is broken

away and discarded.

Ferrule

Stud

Chuck

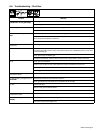

7-4. Recommended Settings

STANDARD TABLE METRIC TABLE

Stud Size Current Time Stud Size Current Time

1/4 Inch 300 Amps .220 Seconds 6 mm 350 Amps .250 Seconds

5/16 Inch 410 Amps .300 Seconds 8 mm 420 Amps .310 Seconds

3/8 Inch 520 Amps .360 Seconds 10 mm 580 Amps .430 Seconds

1/2 Inch 750 Amps .450 Seconds 12 mm 720 Amps .500 Seconds

5/8 Inch 980 Amps .730 Seconds 14 mm 880 Amps .590 Seconds

3/4 Inch 1325 Amps .750 Seconds 16 mm 1040 Amps .660 Seconds

7/8 Inch 1680 Amps .830 Seconds 20 mm 1440 Amps .780 Seconds

1 Inch 2000 Amps .870 Seconds 24 mm 1900 Amps .850 Seconds

The recommended settings are provided as initial settings. Settings may vary per specifications of application. Material surface condition along with lift

and plunge adjustments will vary exact settings.

S Material surface at weld location should be free of dirt, rust and paint.

S Typical adjustments for lift is 3/32 in and plunge is 1/8 in (see Sections 5-7 and 5-8).

S Adjust recommended settings as needed.