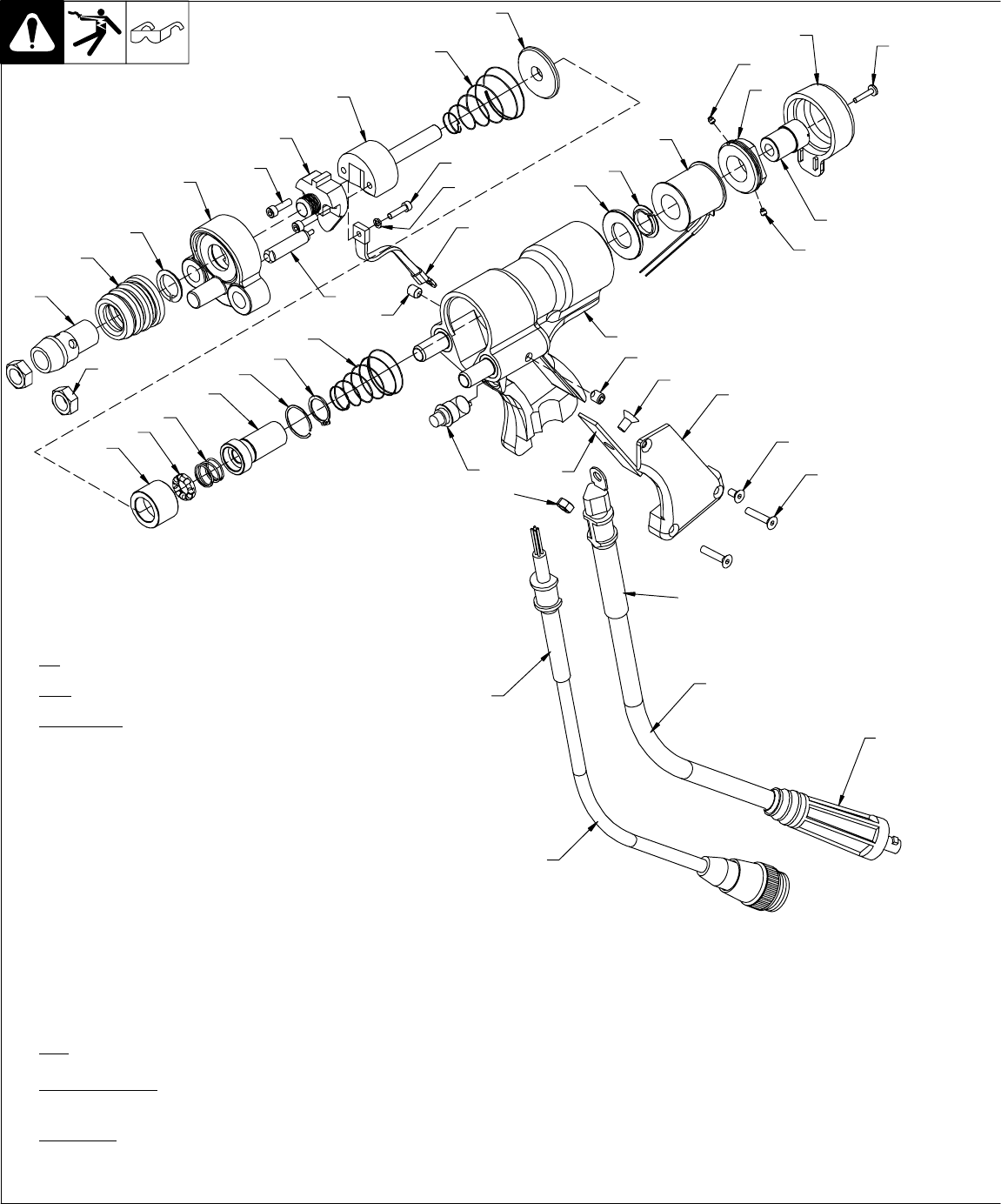

OM-216 244 Page 28

8-3. Maintenance Procedures for Stud Gun

When is Maintenance Required?

Maintenance requirements will vary with environment and usage. Dirty

work areas or high volume stud welding will require more frequent main-

tenance.

There are three primary reasons for maintenance:

• Dirt - Dirt can enter the lifting mechanism and cause erratic lift and

plunge operations. Typically , cleaning is all that is required.

• Wear - Components do wear out over time. Typically, items such

as plastic bearings or cables wear out and need to be replaced.

• Improper Use - Components can arc out by inadvertently placing

them against grounded materials during a weld sequence. Also, by us-

ing the gun as a hammer to test welds will damage parts and require

maintenance.

Maintenance Steps

Proper Maintenance Procedures:

• Disassemble the gun.

• Inspect all parts for wear or damage.

• Replace worn or damaged components.

• Clean all components.

• Reassemble components.

• Adjust settings and test.

Disassembly / Assembly Procedures:

Y To prevent accidental activation disconnect the gun from the

power source before adjusting or servicing the gun.

. Remove all accessories from gun before servicing.

. Items referenced ( ) will correspond with list items.

1 Legs: Loosen set screws (23) and pull legs (not shown) straight out.

Inspect legs for damage and straightness, replace if necessary.

2 Chuck (Not Shown): Insert chuck key into chuck adapter and turn

key 180 degrees. Inspect chuck for damage. If taper on chuck

appear worn out replace chuck.

3 Dust Bellows (3): Remove dust bellows by sliding over end of chuck

adapter. The bellows prevent contaminates from entering the

internal mechanisms of the gun. If bellows has holes or is torn,

replace.

1

2

3

4

5

6

8

7

12

13

14

11

10

23

9

24

4

25

27

26

29

30

28

27

22

23

33

35

36

37

32

31

34

15

16

17

18

19

20

21

38

40

41

42

39