– 30 –

TROUBLESHOOTING GUIDE

To avoid injury from an accidental start, turn the switch OFF and always remove the plug from the power source before

making any adjustments.

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our service website at www.portercable.

com. You can also order parts from your nearest Porter-Cable Factory Service Center or Porter-Cable Authorized

Warranty Service Center. Or, you can call our Customer Care Center at (888) 609-9779.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about Porter-Cable, its

factory service centers or authorized warranty service centers, visit our website at www.portercable.com or call our

Customer Care Center at (888) 609-9779. All repairs made by our service centers are fully guaranteed against

defective material and workmanship. We cannot guarantee repairs made or attempted by others.

You can also write to us for information at

Power Tool Specialists, Inc. 684 Huey Road, Rock Hill, SC 29730,

(888) 609-9779 - Attention: Product Service. Be sure to include all of the information shown on the nameplate of your

tool (model number, type, serial number, etc.).

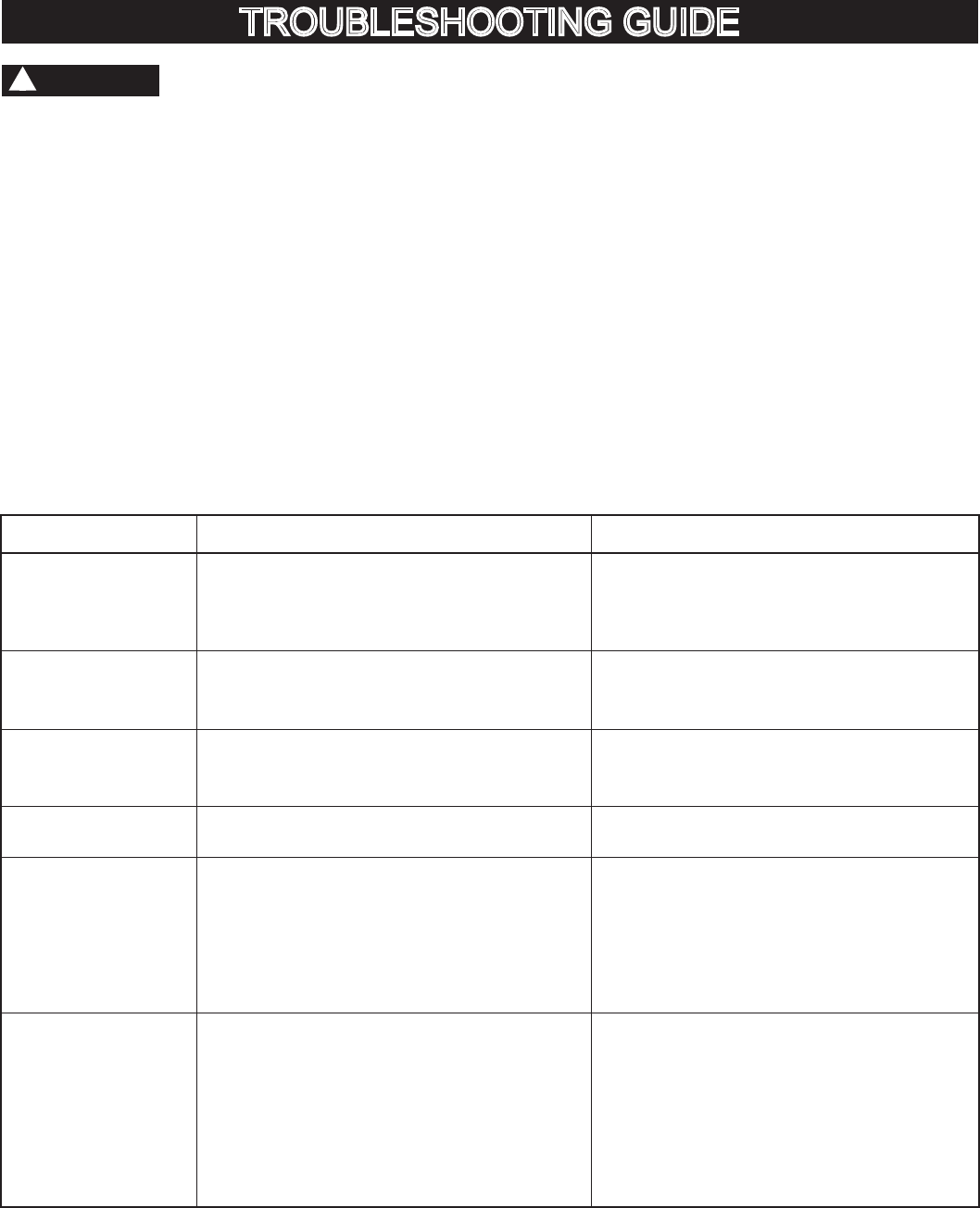

PROBLEM POSSIBLE CAUSES CORRECTIVE ACTION

Saw will not start. 1. Saw is not plugged in.

2. Fuse blown or circuit breaker tripped.

3. Cord is damaged.

1. Plug in saw.

2. Replace fuse or reset circuit breaker.

3. Have cord replaced by Porter-Cable Service

Center or Authorized Service Station.

Does not make

accurate 45°

and

90° rip cuts.

1. Positive stop not adjusted correctly.

2. Tilt angle pointer not set accurately.

1. Check blade with square and adjust

positive

stop.

2. Check blade with square and adjust to zero.

Material pinched blade

when

ripping.

1. Rip fence not aligned with blade.

2. Warped wood, edge against fence is not

straight.

1. Check and adjust rip fence.

2. Select another piece of wood.

Material binds on

riving

knife

.

1.

Riving knife

not aligned correctly with blade. 1. Check and align

riving knife

with blade.

Saw makes

unsatisfactory

cuts.

1. Dull blade.

2. Blade mounted backwards.

3. Gum or pitch on blade.

4. Incorrect blade for work being done.

5. Gum or pitch on blade causing erratic feed.

1. Replace blade.

2. Turn the blade around.

3. Remove blade and clean with turpentine

and coarse steel wool.

4. Change the blade.

5. Clean table with turpentine and steel wool.

Material kicked back

from

blade.

1. Rip fence out of adjustment.

2. Riving knife not aligned with blade.

3. Feeding stock without rip fence.

4. Riving knife not in place.

5. Dull blade.

6. The operator letting go of material before it

is past saw blade.

7. Miter angle lock knob is not tight.

1. Align rip fence with miter gauge slot.

2. Align riving knife with blade.

3. Install and use rip fence.

4. Install and use riving knife. (with guard)

5. Replace blade.

6. Push material all the way past saw blade

before releasing work.

7. Tighten knob.

WARNING

!