16

CHATTER:

Chatter marks usually appear on thin material. See

Figure 21. Even at their lowest point, the table rolls are

too high to handle thin material. Solve the problem by

either using a slave board or making an auxiliary table

out of Formica countertop material, cleating at each end

of the table to keep it stationary.

TAPERS:

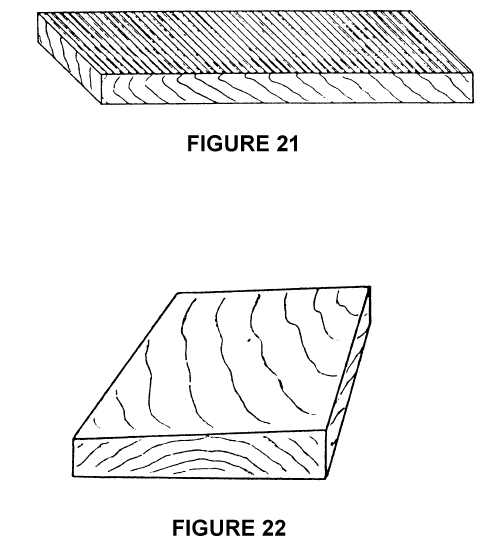

If the machine planes a taper across the full width of the

board, as shown in Figure 22, the table is not parallel

with the cutterhead. First check that all knives are

properly installed with equal protrusion from the

cutterhead. If they are, then the table itself must be

adjusted. See “Table Adjustment” above.

TWISTING:

If material twists while feeding through the planer, either

the table rolls, pressure bar, or outfeed roll may be out

of level. Place the bed and feed roll gauge (or a gauge

block) on the table directly under the right end of the

infeed roll, move table up until light contact is made

between roll and gauge. Move the gauge to the left end

and check. Repeat this process under the chipbreaker,

pressure bar, and outfeed roll until the problem is

discovered. Generally the pressure bar will be out of

level due to its constant adjustment to compensate for

knife wear. At this point, level the pressure bar (or other

part of the planer) and proceed with operation.

HALTED FEEDING:

If the infeed roll takes stock away from you while

feeding, then feeding stops immediately, the

chipbreaker is too low, causing material to hit high on

the heel. Reset the chipbreaker.

In a similar situation, the infeed roll takes the stock, the

chipbreakers lift, and just as you hear the knives contact

the material, then it stops feeding. In this case the

pressure bar is too low. Reset the pressure bar

according to instruction in this manual.