17

MAINTENANCE

Periodic or regular inspections are required to ensure

that the machine is in proper adjustment, that all screws

are tight, that belts are in good condition, that dust has

not accumulated in the electrical enclosures, and that

there are no loose or worn electrical connections.

Buildup of sawdust and other debris can cause your

machine to plane inaccurately. Periodic cleaning is not

only recommended but mandatory for accurate planing.

Close-fitting parts, such as the table locking rods, the

cutterhead slot and gibs, should be cleaned with a cloth

or brush and non-flammable solvent and freed from

clinging foreign matter.

Remove resin and other accumulations from feed rolls

and table with a non-flammable solvent.

Periodically check all the chains for proper tension and

adjust accordingly if required.

TIP: If a foreign object nicks the knives, instead of

throwing them away or trying to grind out the deep nick,

simply stagger the knives in the head, moving one knife

no more than 1/4” to the right and another knife no more

than 1/4” to the left. The nick will not be noticeable.

LUBRICATION

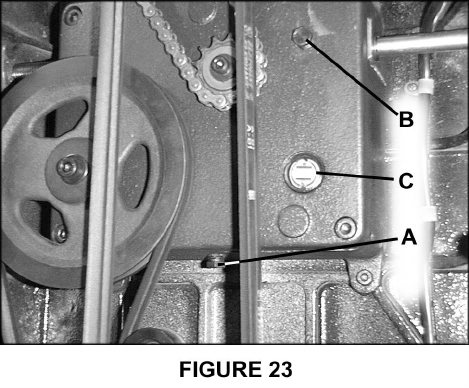

The gear box oil should be changed once a year. The

drain plug (A) is shown in Figure 23. Refill the gear box

with 60-90 weight gear oil through the fill hole (B). The

sight glass (C) should be checked periodically and oil

added as necessary.

The recommended lubrication for roller chains used in

medium to slow speed operation is to simply wipe the

chain clean. When there is an appreciable build up of

dust, dirt or wood shavings, use an oil cloth but never

pour the oil directly on the chain. Over-oiling defeats

the purpose of the lubrication, since it tends to invite the

collecting of dust, shavings, etc. and works into

members of the chain. This hastens wear and leads to

premature replacement.

The bearings on the cutterhead are factory lubricated

and sealed. They require no further attention.