9

INSPECTION

Before putting power to the machine, check that all

screws are tight, that all mechanical functions work

freely and that the cutterhead turns freely without knife

contact with the chipbreaker or pressure bar.

ADJUSTMENTS

Tools required

Philips screwdriver

Hex wrenches (provided)

Open-end wrench (provided)

DEPTH OF CUT

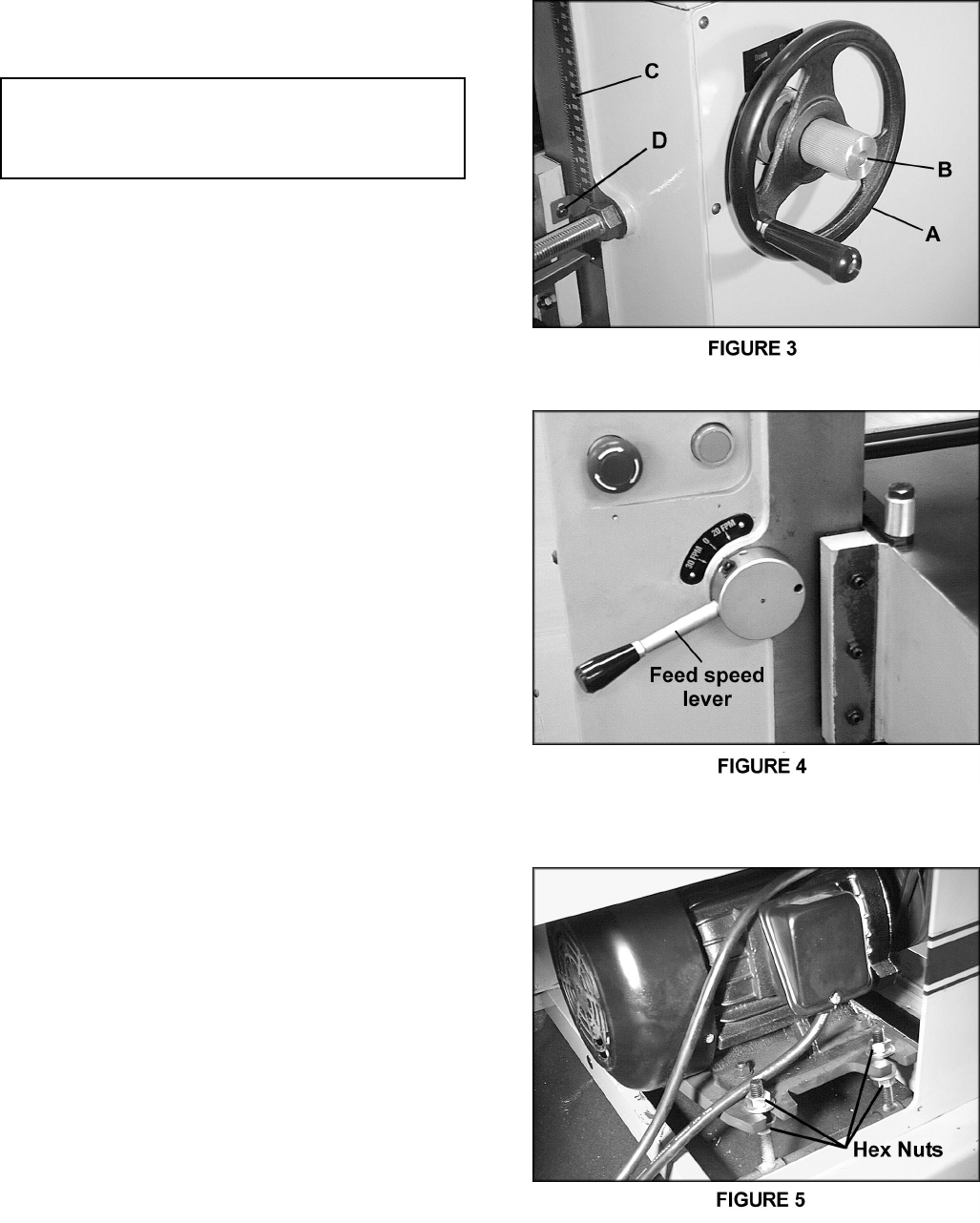

Depth of cut is controlled by raising or lowering the

table. This is done by using the handwheel (A), shown

in Figure 3.

1. Loosen the lock knob (B).

2. Raise or lower the table to the desired position

(clockwise to raise). One revolution of the handwheel

equals 1/16". The distance can be read on the scale

(C).

3. Retighten lock knob (B).

4. The pointer (D) can be adjusted if the scale should

ever need recalibrating.

FEED RATE ADJUSTMENT

The Model 201 is equipped with selectable feed speed

rolls that feed stock at 20 and 30 feet per minute. To

adjust speed, turn lever shown in Figure 4.

IMPORTANT: Always change speeds while the

machine is running.

BELT TENSION

1. Disconnect machine from power source.

2. Remove lower rear panel of machine, and use the

hex nuts to adjust tension. See Figure 5. Adjust motor

plate up or down until correct belt tension is achieved.

To lower motor plate, loosen lower nuts and tighten

upper nuts. To raise motor plate, do the opposite.

3. Correct tension is obtained when there is

approximately 1/4" deflection in the center span of the

belts using light finger pressure.

4. Re-tighten the nuts and replace panel.