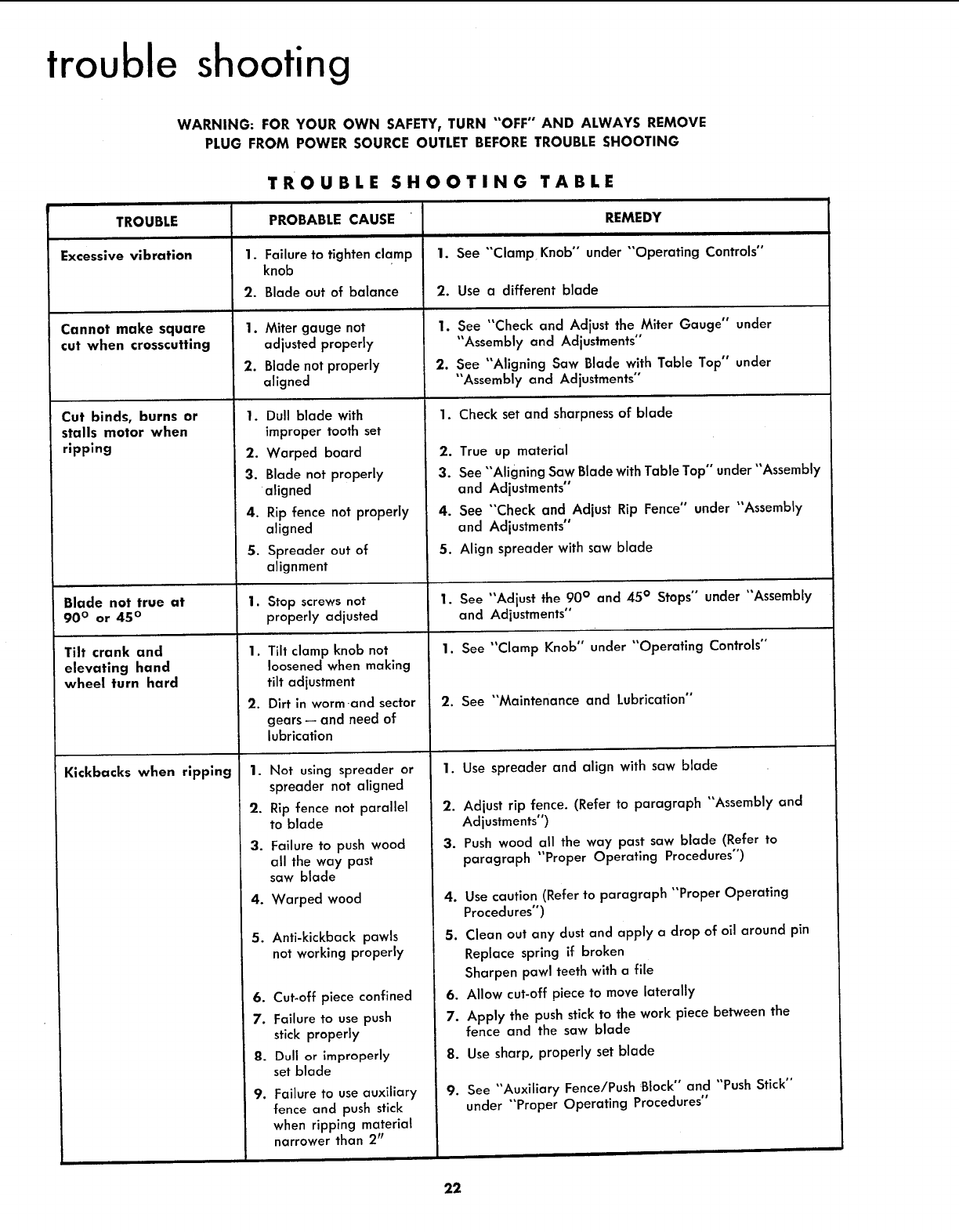

trouble shooting

WARNING: FOR YOUR OWN SAFETY, TURN "'OFF" AND ALWAYS REMOVE

PLUG FROM POWER SOURCE OUTLET BEFORE TROUBLE SHOOTING

TROUBLE SHOOTING TABLE

TROUBLE

Excessive vibration

Cannot make square

cut when crosscutting

PROBABLE CAUSE

1. Failure to tighten clamp

knob

2. Blade out of balance

1. Miter gauge not

adjusted properly

2. Blade notproperly

aligned

Cut binds, burns or 1.

stalls motor when

ripping 2.

Dull blade with

improper tooth set

Warped board

3. Blade not properly

aligned

4. Rip fence not properly

aligned

S. Spreader out of

alignment

REMEDY

1. See "Clamp Knob" under "'Operating Controls"

2. Use a different blade

1. See "Check and Adjust the Miter Gauge" under

"Assembly and Adjustments"

2. See "Aligning Saw Blade with Table Top" under

"Assembly and Adjustments"

1. Check set and sharpness of blade

2. True up material

3. See "Aligning Saw Blade with Table Top" under "Assembly

and Adjustments"

4. See "'Check and Adjust Rip Fence" under "Assembly

and Adjustments"

5. Align spreader with saw blade

Blade not true at 1. Stop screws not 1. See "Adjust the 90 ° and 45 ° Stops" under "Assembly

90 ° or 45 ° properly adjusted and Adjustments"

1. 1. See "Clamp Knob" under "Operating Controls"

2.

Tilt clamp knob not

loosened when making

tilt adjustment

Dirt in worm and sector

gears-- and need of

lubrication

1. Not using spreader or

spreader not aligned

2. Rip fence not parallel

to blade

3. Failure to push wood

all the way past

saw blade

Warped wood

Tilt crank and

elevating hand

wheel turn hard

Anti-kickback pawls

not working properly

Kickbacks when ripping

4.

5.

6. Cut-off piece confined

7. Failure to use push

stick properly

g. Dull or ;rnproperly

set blade

9. Failure to useauxiliary

fence and push stick

when ripping material

narrower than 2"

2. See "Maintenance and Lubrication"

1.

2.

3.

Use spreader and align with saw blade

Adjust rip fence. (Refer to paragraph "Assembly and

Adjustments")

Push wood all the way past saw blade (Refer to

paragraph "Proper Operating Procedures")

4. Usecaution (Refer to paragraph "Proper Operating

Procedures")

S. Clean out any dustand apply a drop of oil around pin

Replace spring if broken

Sharpen pawl teeth with a file

6. Allow cut-off piece to move laterally

7. Apply the push stick to the work piece between the

fence and the saw blade

8. Use sharp, properly set blade

9.

See "'Auxiliary Fence/Push :Block" and "Push Stick"

under "'Proper Operating Procedures"

22