1

Form A348B

Date 2007January9/B

Page 1 of 2

Printed In U.S.A.

INSTRUCTIONS FOR

SIOUX NO. 1980, 1981, 1982, 1983

AIR ROUTERS,

NO. 1985 AIR DIE GRINDER

AIR SUPPLY

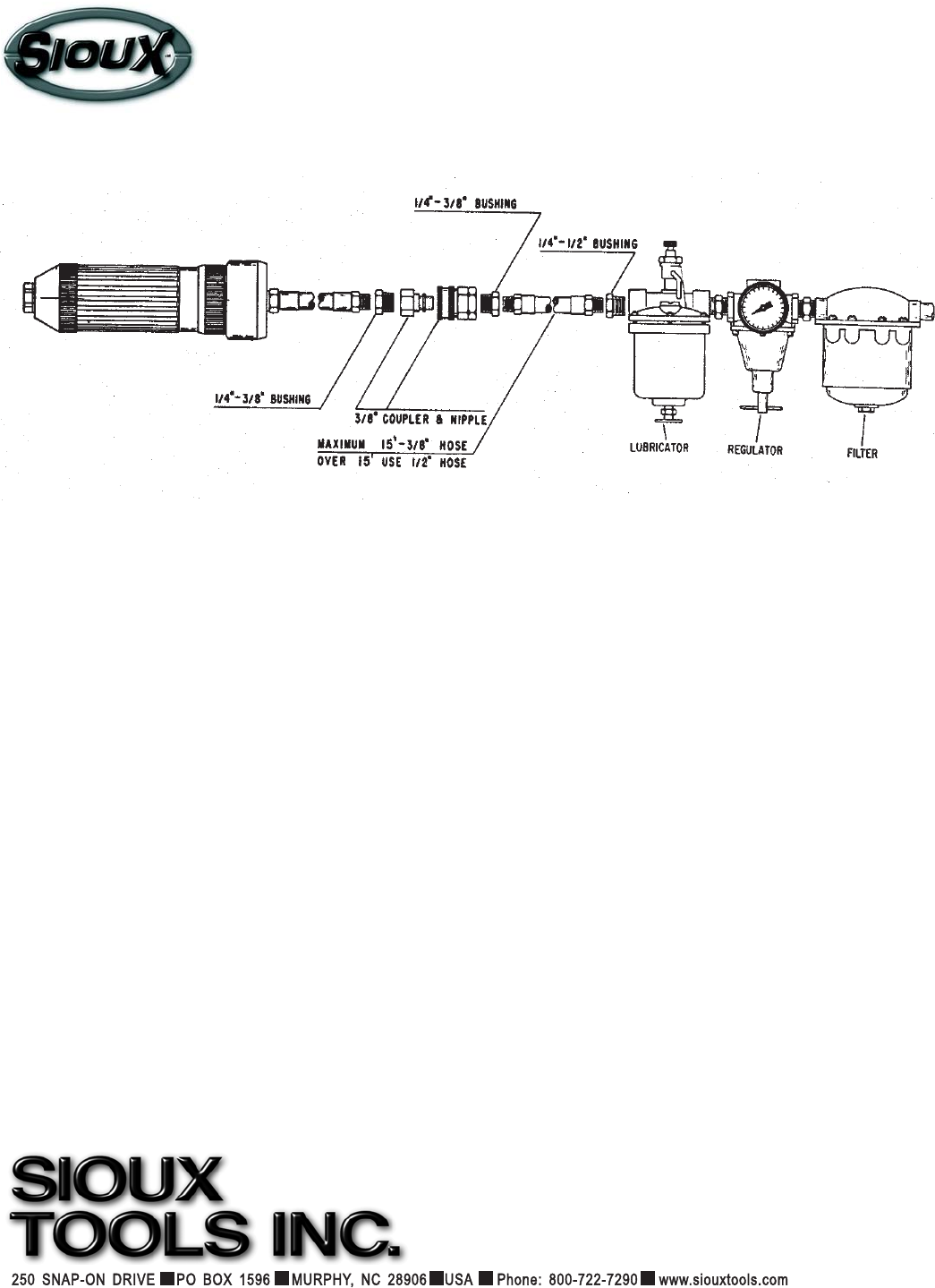

These power units are designed for operation on clean, dry air at a Pressure of 90 p.s.i. Line filters, lubricators and a

pressure regulator will insure that the air supply is properly conditioned.

Even the best air systems accumulate dirt and moisture over a period of time. Blowing out hoses and air lines periodi-

cally will help prolong motor life.

HOSE

A special 3/8 I.D. hose is provided. It is more flexible than comparable rubber hoses and has a swivel fitting at the tool

end. If an extremely long extension hose is required (over 25 feet), use 1/2 I.D. hose with 3/8 quick couplings.

MOTOR LUBRICATION

An air line lubricator set to deliver 1-2 drops per minute is recommended.

SPEED CONTROL

Speed of the tool may be adjusted by turning the slotted speed control which is accessible thru a hole in the valve

operator ring.

MAINTENANCE

To flush motor, disconnect air hose and pour petroleum solvent into the air inlet. Connect to air line and run motor, then

lubricate with oil.