Servicing the Fluid Section

Use the following procedures to service the valves and repack

the fluid section. Perform the following steps before

performing any maintenance on the fluid section.

1. Loosen and remove the four front cover screws. Remove

the front cover.

2. Position the crankshaft/slider assembly at the bottom,

dead-center of its stroke so that the connecting pin and

retaining ring are visible below the slider assembly. This

is done by turning the sprayer on and off in short bursts

until the connecting pin is visible below the slider housing.

3. Turn off and unplug the unit.

Before proceeding, follow the Pressure Relief Procedure

outlined previously in this manual. Additionally, follow all

other warnings to reduce the risk of an injection injury,

injury from moving parts or electric shock. Always unplug

the sprayer before servicing!

4. Remove the return hose from the clamp on the siphon

tube.

5. Unscrew the siphon tube/siphon set from the foot valve.

6. Loosen and remove the high-pressure hose from the

nipple on the back of the upper housing of the fluid

section.

Servicing the Valves

The design of the fluid section

allows access to the foot valve and

seat as well as the outlet valve and

seat without completely

disassembling the fluid section. It

is possible that the valves may not

seat properly because of debris

stuck in the foot valve seat or outlet

valve seat. Use the following

instructions to clean the valves and

reverse or replace the seats.

1. Loosen and remove the foot

valve housing from the lower

housing.

2. Clean out any debris in the foot

valve housing and examine the

housing and the foot valve

seat. If the seat is damaged,

reverse or replace the seat.

3. Using two wrenches, hold the

upper housing at the wrench

flats with one wrench and loosen the lower housing with

the other. Remove the lower housing.

4. Using a 3/4” wrench, loosen and

remove the outlet valve retainer

from the piston rod.

5. Clean out any debris and

examine the retainer and outlet

valve seat. If the seat is

damaged, reverse or replace the

seat.

6. Remove, clean, and inspect the

outlet valve cage and outlet valve

ball. Replace if they are worn or

damaged.

7. Reassemble the valves by reversing the steps above.

NOTE: Always service the

outlet valve with the

piston rod attached to

the pump. This will

prevent the piston rod

from rotating during

disassembly of the

outlet valve.

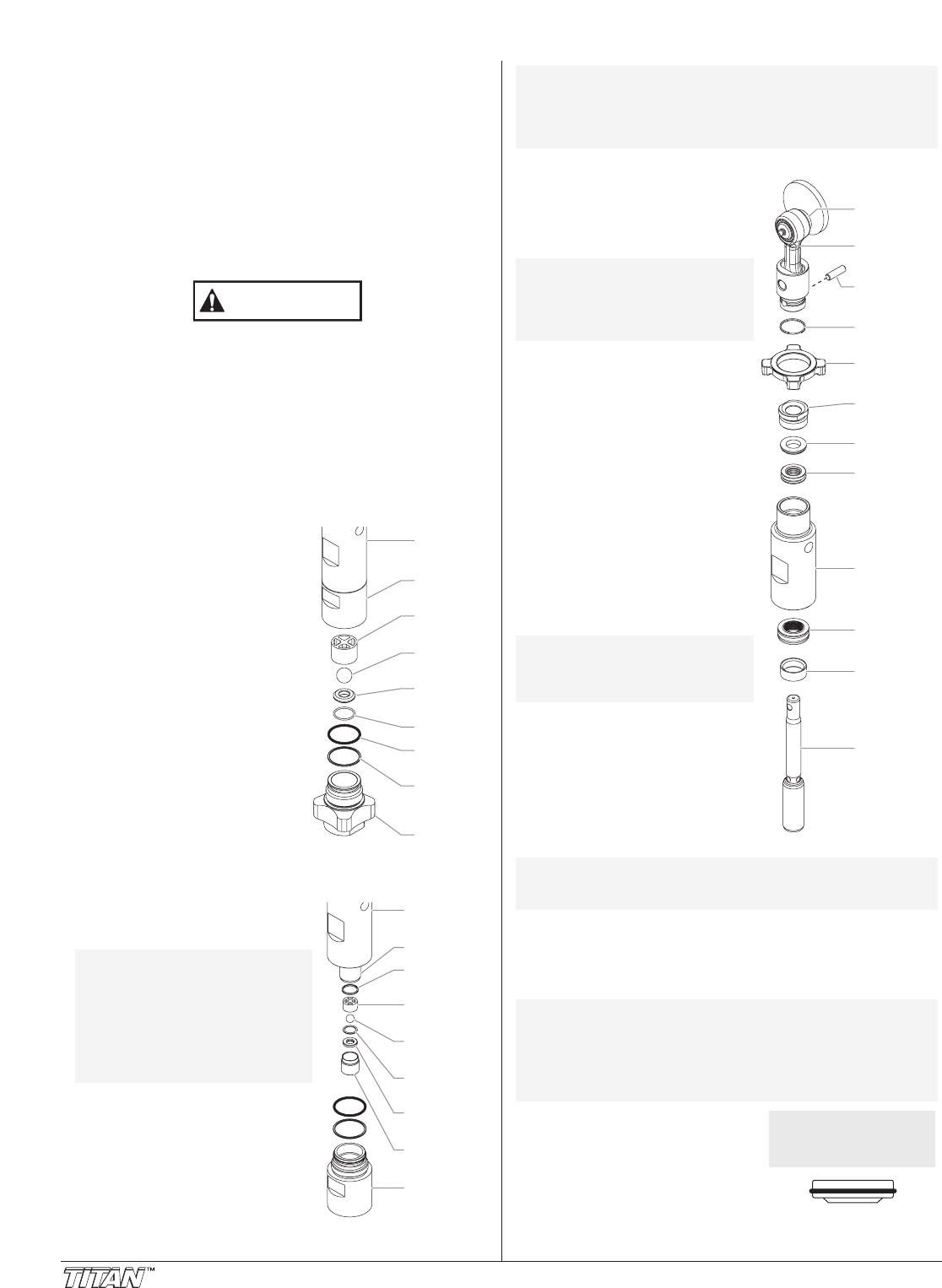

Outlet Valve

Retainer

Nylon

Washer

Outlet Valve

Seat

Outlet Valve

Ball

Outlet Valve

Cage

Outlet Valve

Seal

Piston Rod

Upper

Housing

Lower

Housing

Foot Valve

Housing

Black

O-Ring

O-ring

White

Back-Up

Ring

Foot Valve

Seat

Foot Valve

Ball

Foot Valve

Cage

Lower

Housing

Upper

Housing

WARNING

10 ©Titan Tool Inc. All rights reserved.

Repacking the Fluid Section

1. Remove the foot valve

assembly and the lower

housing using the steps in the

“Servicing the Valves”

procedure above.

2. Slide the retaining ring up on

the slider assembly to expose

the connecting pin.

3. Push the connecting pin back

through the slider assembly

and piston. The connecting

pin will fall into a recessed

area of the gear box housing

where it can be retrieved.

4. Tap the knock-off nut with a

soft hammer so that it turns

counterclockwise and loosens.

5. Turn the fluid section

counterclockwise to remove it

from the gear box housing.

6. Place the upper housing

upright in a vise by clamping

on the wrench flats.

7. Using a wrench, remove the

upper seal retainer.

8. Slide the piston rod out

through the bottom of the

upper housing.

9. Inspect the piston rod for wear

and replace if necessary.

10. Remove the upper and lower

packings from the upper housing.

11. Clean the upper housing. Inspect the upper housing for

damage and replace if necessary.

12. Locate the new upper and lower packings and remove the

pre-form tools. Save the upper packing pre-form tool for

use as the piston insertion tool later in this procedure.

13. Pack the areas between the

packing lips with grease.

Lubricate the o-rings on the

exterior of the packings with

grease.

14. Insert the upper packing into the

top of the upper housing with

the raised lip on the packing

facing down.

Install upper packing

with raised lip

facing down.

Raised Lip

NOTE: The factory-installed packings are black in

color. The replacement packings in the packing

replacement kit are white.

Do not remove the pre-form tools from the

upper and lower packings until immediately

before they are installed into the upper housing.

NOTE: Be careful not to scratch, score, or otherwise

damage the upper housing during removal of

the packings.

NOTE: Do not over-tighten

the vise. Damage to

the upper housing

may occur.

NOTE: The outlet valve does

not need to be

disassembled from

the piston rod for this

procedure.

Retaining

Ring

Connecting

Pin

Slider

Assembly

Crankshaft

Knock-Off

Nut

Upper Seal

Retainer

Spacer

Upper

Packing

Lower

Packing

Upper

Housing

Piston Rod

Wear Ring

NOTE: During reassembly, make sure the black o-rings

and the white back-up rings between the upper

housing and lower housing as well as between

the lower housing and the foot valve housing

are lubricated with grease and in position.