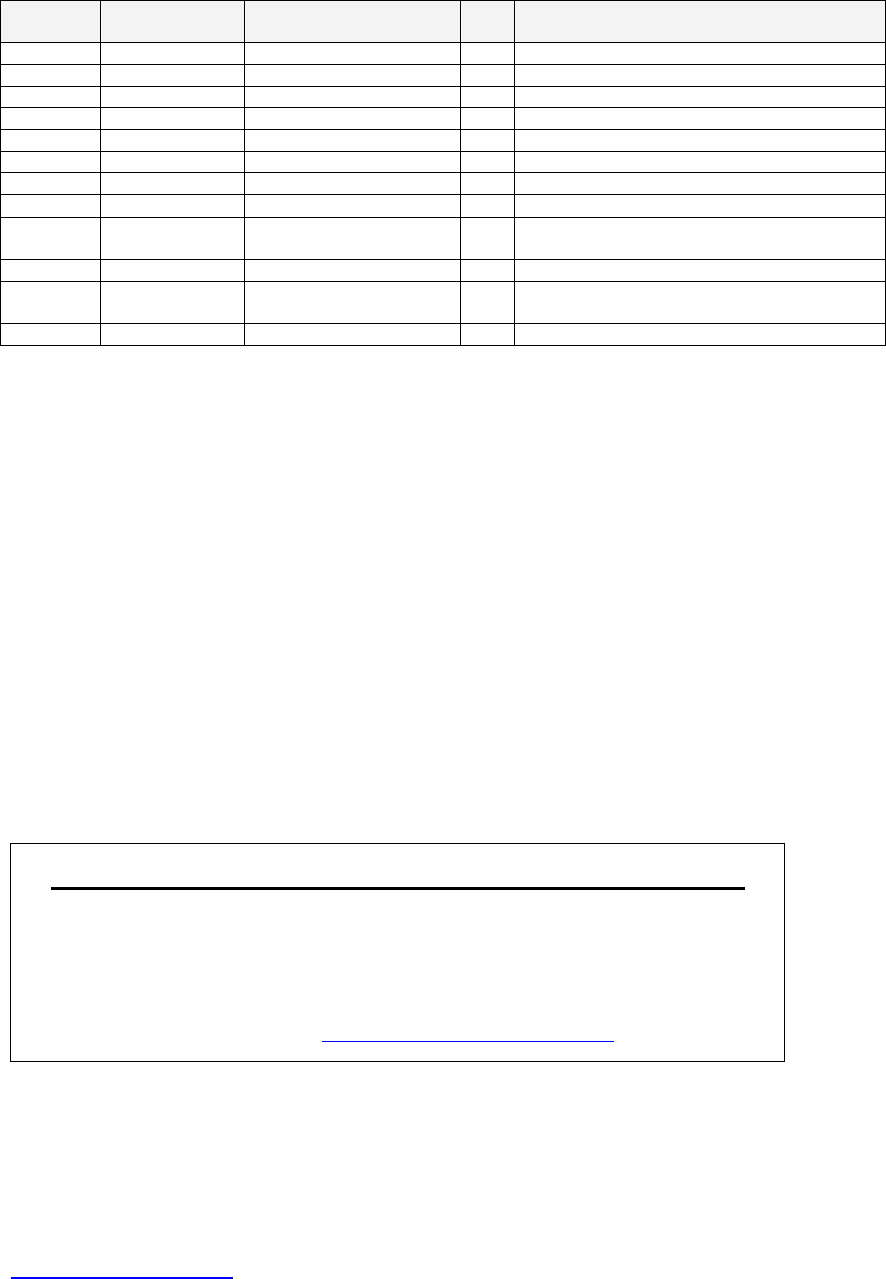

Parts no.

Figure no.

(ID number)

Part name Qty Guideline for parts exchange

38 150406 Tras bis (M4 x 6) 1

39 60736 Skirt band 1 When the deformed or damage is found.

40-1 110310 Screw (M3 x 10) (1)

40-2 2103 Nut (M3) (1)

41 Cap 1

42 60733 Skirt 1 When cut or cracked or worn-out.

43 130305 Screw (M3 x 5) 4

44 60735

φ30 x 4t pad

1 When surface flatness is lost

45 60738 Speed controller

(exclusive product)

1 When parts become worn such as the inlet

screws

60 60740 Housing 1

61 60741 Throttle Valve 1 When outer diameter is worn and air leaks

seriously from the valve pin sleeve joint

62 60742 Valve Plug 1

f. Assembly method

- Before assembly, clean each part and check for wear or damage. Use only proper

spare parts.

- Apply lubricant oil lightly on each part.

- Replace damaged O rings. Install O rings using grease (multipurpose grease - Military

Specifications G-46006, or equivalents).

- Assemble the parts carefully in reverse order from disassembly.

- Carefully confirm end clearance in the motor.

- Do not over-tighten the cup lock.

- When installing the angle housing, install the cap in the end of the angle housing

beforehand. Tighten the cup lock while confirming the position of the angle housing.

- Install the EX, shaft Assy., while confirming proper meshing of the gears. Never

assemble the gears to hit tooth to tooth.

- After assembly, look for loose or missing screws.

- Apply lubricant oil into the air inlet, and run the tool at a medium pressure to make sure

it rotates freely.

Repair services after Warranty period & Parts supply contact

Tool Warehouse Inc.

Contact: Jeff Houk

3410 East 42

nd

Street,

Minneapolis, MN 55406-3333

Phone: 1-612-722-4260 Fax: 1-612-722-3415

e-mail:

sales@ToolWarehouseInc.com

3M Industrial Business Quality Direct / abrasives

Phone: 1-800-362-3550 (USA only)

3M Industrial Business Customer Response Center

900 Bush Avenue, Building 21-1W-10

St. Paul, MN 55106

Phone: 1-866-279-1235

www.3M.com/abrasives © 3M 2006

11