39

Troubleshooting

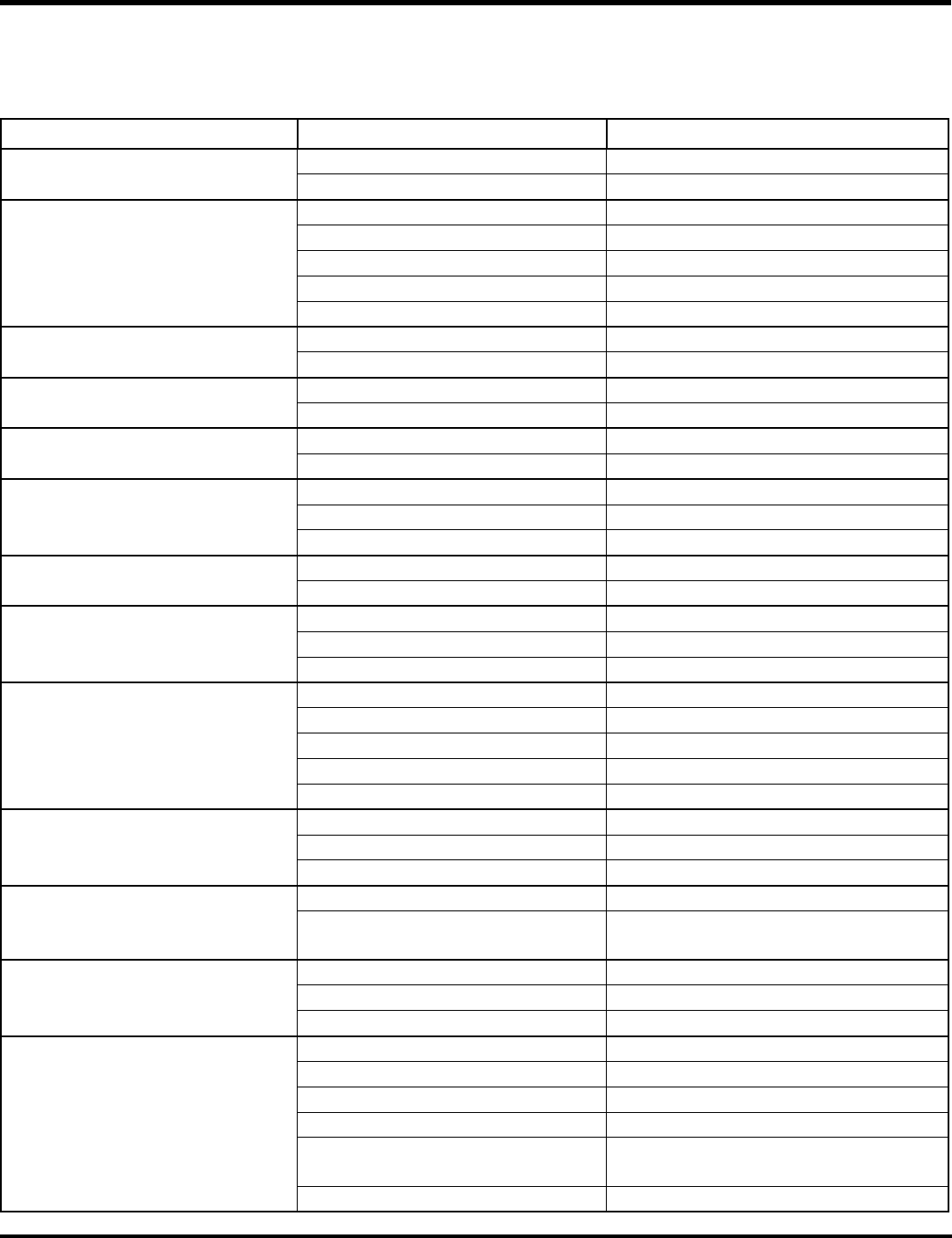

Problem Cause Remedy

Bad Spray Pattern

Air cap or nozzle clogged Clean with appropriate solvent

Bentuidneedle Replaceuidneedle

Blistering

Moisture on surface Clean surface

Wrong solvent Check solvent

Coats not compatible Check material compatibility

Insufficient dry time Longer dry time

Surface too cold Warm surface

Fish Eyes

Air contamination Add air filtration

Silicone contamination Clean surface with solvent

Heavy Middle Pattern

Toomuchuidpressure Reduceuidpressure

Not enough atomizing pressure Increase atomizing pressure

Intermittent Pulsating Spray

Worn or loose packing Tighten or replace

Lowuidpressure Adduidorincreaseuidpressure

Insufficient Fluid Flow, Pressure Feed

RestrictioninuidlineBlockedhose Use3/8”uidhoseFlushorreplacehose

Fluid nozzle too small Use larger needle/nozzle

Lowuidpressure Increaseuidpressure

Coarse or Lumpy Surface

Dirt or dust on surface Tack wipe before spray

Material is contaminated Change or strain

Mottled Looking Surface

Coating too thin Use less thinner

Coats too wet Use less thinner

Improper spray technique Ensure gun is parallel to work

No Paint Flow

Cloggeduidnozzle Cleanuidnozzle

Lossofuidpressure Out of paint

Clogged air passage Clean with solvent

Restrictioninmat’lhose Flush with solvent

Clogged check valve Replacecheckvalve

Orange Peel

Paint drying too fast Use proper solvent

Gun too far from target 6-8 inches is ideal

Viscosity too high Reducewithsolvent

OversprayisExcessive

Gun too far from target 6-8 inches is ideal

Too much atomizing air for coating being

sprayed

Reduceatomizingair

Pin-Holing, Solvent Pops

Trapped solvent Apply lighter coats

Improper solvent Check coating manufacturer

System contaminated Clean all parts

Paint Leak

Wrong needle size Replace

Damaged-worn needle Replace

Looseuidnozzle Tighten or replace

Worn/loose packing nut Tighten or replace

Needle not closing

Packing too tight. Broken or missing needle

spring. Dried paint on needle.

Looseuidtting Tighten or replace