13

ADJUSTING BLADE

TENSION

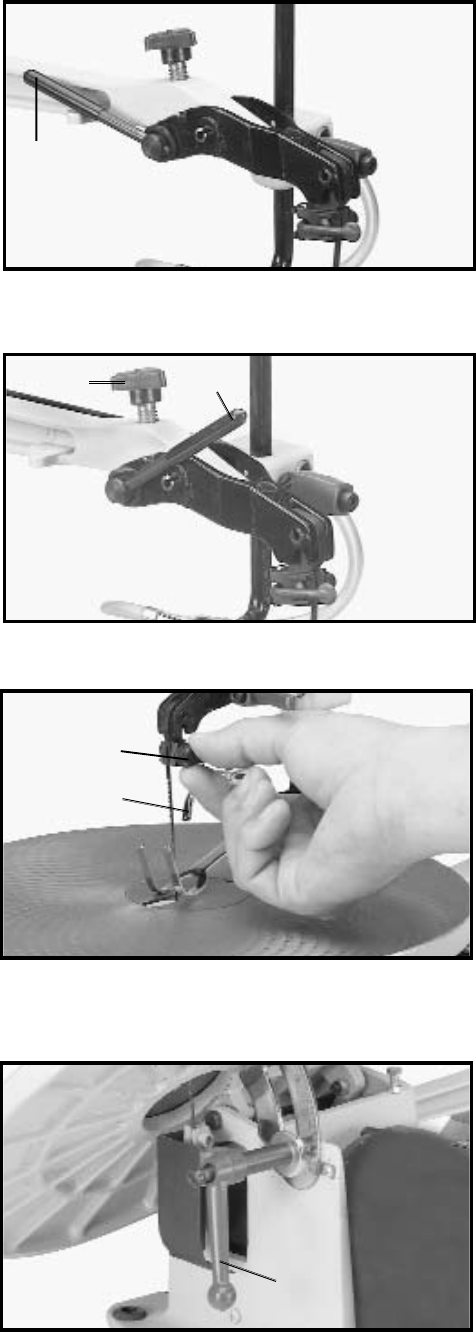

Tension is applied to the blade when the blade tension

lever (A) Fig. 27, is in the rear position, as shown.

When the lever (A) is moved forward, as shown in Fig.

28, blade tension is released.

When adjusting blade tension, lever (A) should be in

the forward position, as shown in Fig. 28. To increase

blade tension, turn knob (B) Fig. 28, clockwise and to

decrease blade tension, turn knob (B)

counterclockwise. NOTE: It is necessary to adjust the

blade tension knob (B) only when the blade is removed

from both upper and lower blade holders and a new or

different type of blade is assembled to the holders. It is

not necessary to adjust blade tension when the blade is

removed and replaced in only the upper blade holder as

in performing inside cutting operations.

Adjusting the blade for proper tension is usually

accomplished by trial and error. One method is to pull

back on the blade tension lever (A) Fig. 28, the blade

should start to have tension (resistance) when the

blade tension lever is half way between open Fig. 28,

and closed Fig. 27. Finer blades require more

tensioning while thicker blades require less tension.

Fig. 27

Fig. 28

A

A

B

ADJUSTING

CLAMPING ACTION OF

UPPER BLADE HOLDER

Different widths of scroll saw blades will make it

necessary to adjust the clamping action of the upper

blade holder. It should be noted, however, that very little

adjustment is necessary and very little clamping force is

required to hold the blade.

1. Move the chuck locking lever (C) Fig. 23, to the

rear (open) position, as shown.

2. Turn locknut (C) Fig. 29, clockwise to tighten and

counterclockwise to loosen the clamping action of the,

blade holder. Very little movement of locknut (C) is

necessary.

Fig. 29

A

C

Fig. 30

TILTING THE TABLE

The table on your scroll saw can be tilted 45 degrees to

the left for bevel cutting operations by loosening table

lock handle (A) Fig. 30, tilt the table to the desired

angle and tighten lock handle (A).

A