SET-UP

WARNING: Be sure to use appropriate

protective gear and unplug unit.

WARNING: Make sure area is well

ventilated and free of flammable vapors.

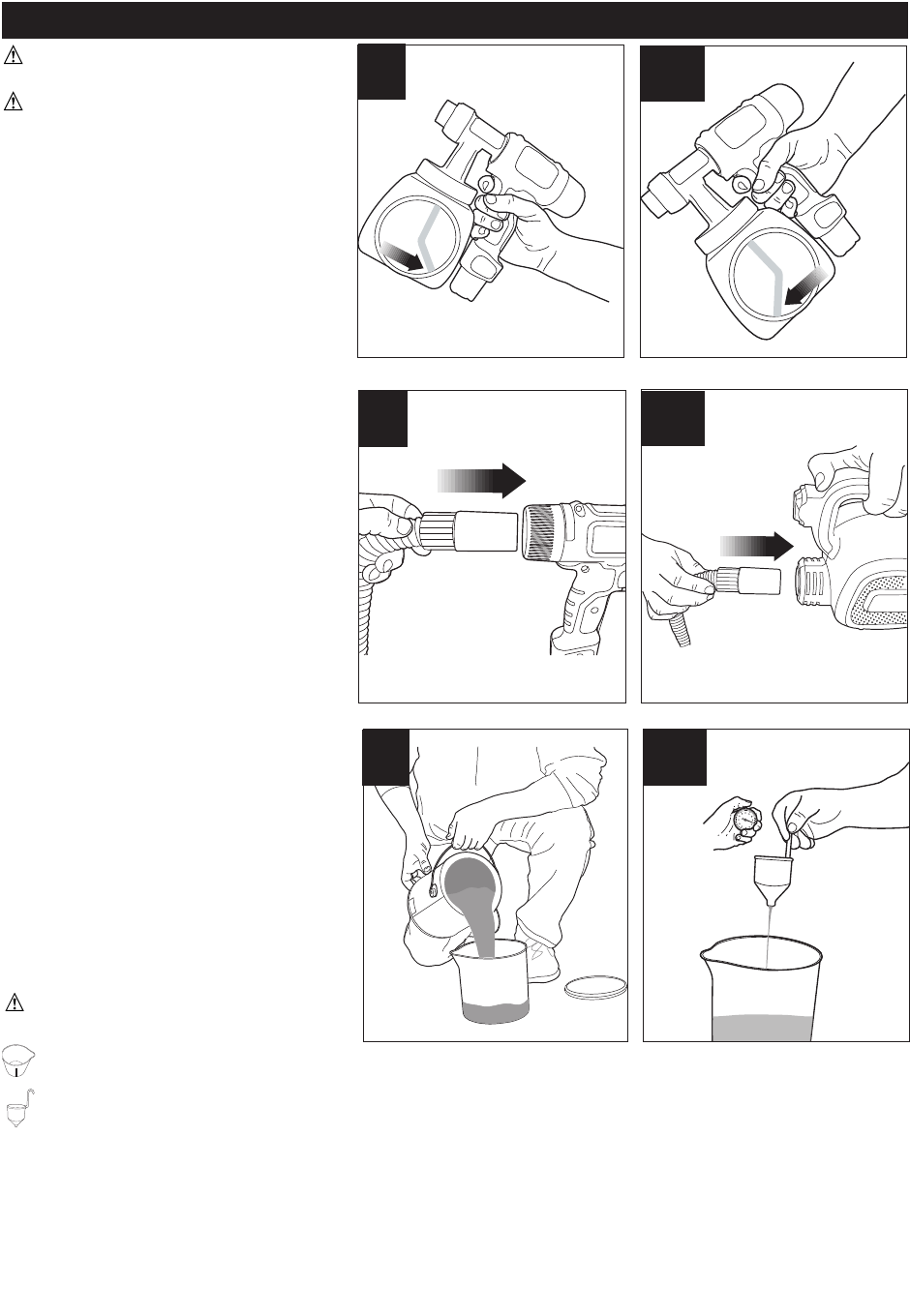

ALIGNING THE PICKUP TUBE -

(

FIGURES B AND B1)

T

he pickup tube can be aligned in the

d

irection that you will be doing the most

spraying to help minimize the amount of

times that you will have to refill the canister.

• If you are spraying at an upward angle or

straight on, position the pickup tube

(figure B) toward the back of the canister.

• If you are spraying at a downward angle,

position the pickup tube (figure B1) toward

the front of the canister.

This will ensure you spray as much material

as possible before you need to refill.

ATTACHING THE AIR HOSE - (FIGURES C

AND C1)

• Insert one end of the air hose into the back

of the sprayer. A slight twisting action when

inserting the hose will help insure a snug fit.

• Insert the other end of the air hose into the

back of the power unit. A slight twisting

action when inserting the hose will help

insure a snug fit.

LIQUID MATERIAL PREPARATION -

(FIGURES D, D1 AND D2)

TIP: Make sure the type of material you

use can be cleaned with either mineral

spirits or paint thinner (for oil-based

paints) or a warm water and soap solution

(for water soluble paints like latex). Use

drop cloths during pouring, mixing, and

viscosity testing of materials to be

sprayed to protect your floors and

anything else in the spraying area that

you wish to remain untouched.

The liquid being sprayed may need to be

thinned (diluted) before starting. When

thinning, use the proper liquid thinner

recommended on the container by the

material manufacturer.

WARNING: Do not use materials with

a flashpoint higher than 60°C (140°F) .

A 2-

3

/4 quart mixing bucket is provided

to use when transferring spray material from the original container into the bucket for thinning and measuring

purposes (figure D).

A viscosity test cup is provided to determine the “runout time” of the material being used.

• Before measuring for the proper viscosity, stir the material throughly.

• Dip the viscosity cup into the material being sprayed and fill the cup completely.

• With the cup held over the material container, measure the amount of time it takes for the stream of material flowing

out to “break” or stop being a constant stream out of the bottom of the cup (2 minutes or less) (figure D1). This is the

“runout time” Refer to the thinning table for information on the thinning required for different materials.

6

B

B1

C

D

D1

C1